Why are one-story frame houses attractive? One-story frame houses for permanent residence

One-story projects frame houses appeared relatively recently. They have gained great popularity due to the rapid construction of the structure and the possibility of saving on heating the house, because the main part of the heat loss occurs through doors and windows. In this article we will analyze in detail the projects of frame houses and their advantages.

Features of frame construction

The frame house project includes the construction of several separate elements:

- racks;

- strapping;

- lumber;

- additional components.

The timber is used with a thickness of 50 mm or 200 mm; if necessary, material with a thicker cross-section is used. The structure is assembled on site, connecting it with staples, nails or other fasteners. The distance between the load-bearing beams is determined based on the conditions of rigidity and the choice of material for the cladding. Each work process is carried out in stages. For the strength of the structure, it is necessary to install heat and waterproofing, as well as install a deep foundation. With high-quality insulation, the temperature inside the house will be comfortable for living. Construction of a one-story frame house is possible at -70 and +50 degrees.

Advantages of frame buildings

- Fast construction. The average amount of time to build a frame house is 40 days. If the work is carried out by a team, the entire process takes a maximum of 3 weeks.

- Low cost. Compared to other materials, such projects are cheaper. The price depends on the chosen product and construction technology. Average price for projects one-story houses with an area of 105 m varies from 22 to 48 thousand dollars.

- Low costs for the heating system. This design is considered the warmest due to the fact that the wall thickness of 150 mm replaces 2 meters of brick wall.

- There is no need to update the façade of the house. With proper operation, the structure can last more than 50 years without major repairs.

- The absence of shrinkage of the foundation allows you to begin finishing the façade immediately after completion of construction.

- It is highly resistant to fire. During the installation process, non-combustible insulation is used inside, and non-combustible siding is used on the outside.

- A frame house can be built on a hilly and uneven surface.

- A smooth surface prevents the formation of cracks and the formation of air flows into the thickness of the walls.

- Due to the small thickness of the walls (30 cm), it is possible to increase the usable area.

- Construction can be carried out without the use of special equipment; for this, all processes should be studied.

Disadvantages of frame houses

- Most manufacturers try to save money on materials, so the frame of a house is often made of boards rather than timber. It is for this reason that the maximum service life is 50 years.

- When attaching heavy objects to the wall, additional blocks must be laid. These nuances should be taken into account at the design stage.

- A frame house has a high sound, any knock will be heard throughout the house. To eliminate this drawback, we recommend installing high-quality sound insulation.

- Carry out thorough sealing of all connections. Most often, mineral wool is used as insulation; with a strong gust of wind, it can simply be blown out of the joints.

Types and projects of frame construction

Single-story frame houses turnkey projects require a lot of work involving specialists. For correct compilation project documentation it is necessary to calculate all materials and develop a layout of all communication systems. The speed of building a house will depend on the number of people doing the work and the availability of all materials. It is possible to determine the final cost of the building only after completing the following work:

- development and approval of drawings in accordance with all construction and fire regulations;

- design of installation of all communications (gasification, sewerage, water supply and electricity);

- soil analysis, choice of foundation type;

- wall thickness and choice of rafter system.

Today, architects offer ready-made building plans that cost from $1,000. This is convenient because you save time and money on collecting all the data. The finished structures are already fully adapted to the type of soil and have all the markings for communications. Such a structure is simply transferred to the site and you get a ready-made frame house For permanent residence. One-story frame houses use two types of projects:

- Finnish;

- Canadian.

One-story frame houses according to Finnish design are built for permanent residence. Beams are used as the material, the entire structure is sheathed with OSB panels, insulation is laid, and after the entire assembly, interior and exterior finishing is performed.

The Canadian project is distinguished by its reliability and high thermal insulation qualities. You can live in such a house all year round. They build a house from SIP panels, which are cut according to the building design, taking into account window and doorways. This approach to work allows us to minimize the amount of waste and maximize the use of material. The photo shows the project of a Canadian house

The main features of the two types of buildings are that all communications will be located on the 1st floor, and the development and implementation of the project will not require much time. Similar designs - best option for a small budget. The photo shows project 1 storey building in Finnish style

For information! Recommended insulation thickness frame structures for permanent residence it must correspond to the width of the wall panels. As thermal insulation material use polystyrene foam, roll or fill insulation.

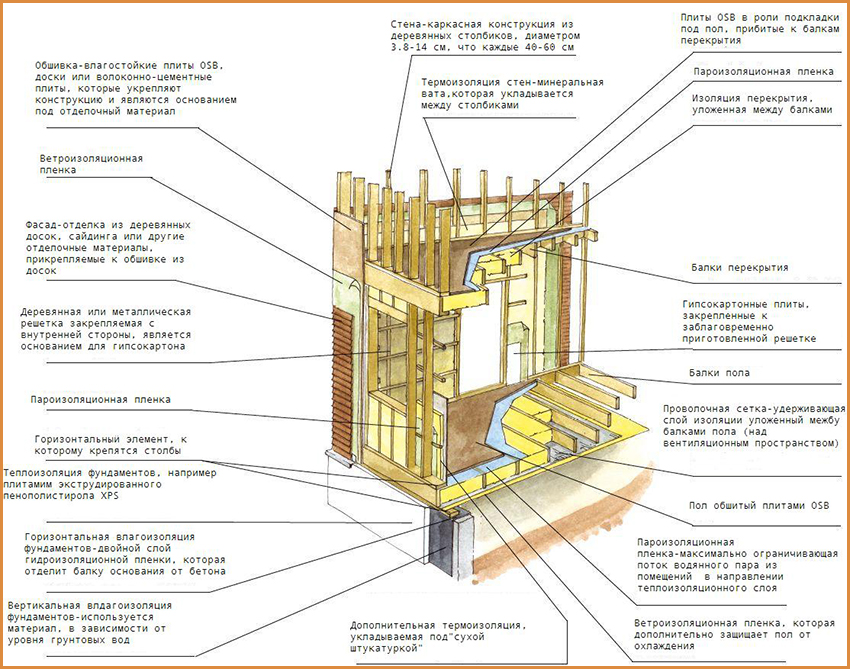

The process of constructing houses for permanent residence

Construction begins with the construction of the foundation and frame. When using SIP panels, the frame does not need to be installed, because they are a full wall. Assembling a house is reminiscent of a construction set; all parts are assembled and adjusted according to the drawing at the factory. Such panels are used to create floor structures and roofs, and, as a rule, they are already ready for exterior and interior decoration. If the house is built without the use of panels, then first of all they install a frame, cover it with waterproofing and insulate it. The outside is covered with OSB boards, and a vapor barrier is laid inside the house.

Important! Don't use cheap ones Construction Materials. The longevity of the house and health depend on them. This is especially true for insulation and slabs, because... low-quality products can release toxins and toxic substances that have a negative impact on the human condition.

There are frame technologies for constructing a foundation, installing a frame, finishing it - all these stages of work should be taken into account and carried out correctly. You cannot skip or ignore any moment, because... this will negatively affect the performance of your 1-story building. The main criteria for successful construction are:

- quality of materials;

- compliance with technology;

- experience of involved specialists;

- project cost.

One-story frame houses and their projects are quite difficult to complete on your own. To build such structures, it is necessary to understand and know the nuances of the work, have certain skills and the necessary tools.

For each of us, home is a very personal and important concept. For architects, this is a common job. But this word evokes the greatest emotions among developers. They are at that stage when it is already too late to give up, and there is still nothing to be happy about.

When choosing a project, many today pay attention to frame houses. Like others, they look very nice in pictures, but since this is a relatively new business for Russia, there are a lot of myths around them. Some promise a fairy-tale palace for little money, while others, on the contrary, dissuade, assuring that this very money will be thrown away - the house will be cold and uninhabitable. Meanwhile, developers are increasingly choosing frame houses, and more and more of them are appearing in the vastness of Russia.

A little about technology

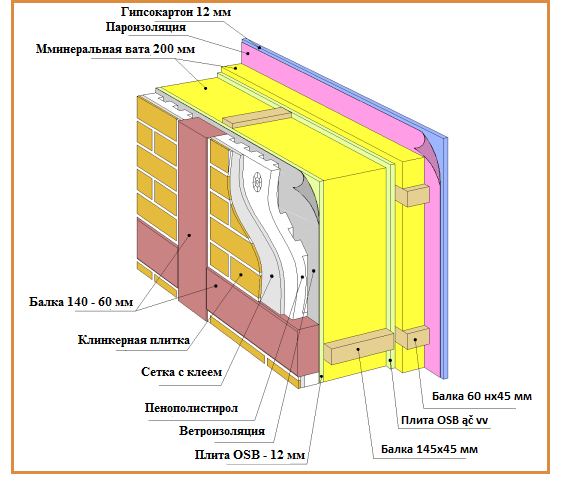

Frame houses, as their name implies, usually have a wooden frame at their base, but now metal technologies have appeared. The frame is made up of beams and sheathed externally and internally with panels with interlayers, insulation and various kinds fixatives. Today these panels are called sandwich panels, SIP, or panel panels. Their manufacturing technology varies, but the essence remains the same. In short, it is tied at the bottom and top wooden frame, covered with OSB board inside and outside, insulated with insulation.

Frame houses, as their name implies, usually have a wooden frame at their base, but now metal technologies have appeared. The frame is made up of beams and sheathed externally and internally with panels with interlayers, insulation and various kinds fixatives. Today these panels are called sandwich panels, SIP, or panel panels. Their manufacturing technology varies, but the essence remains the same. In short, it is tied at the bottom and top wooden frame, covered with OSB board inside and outside, insulated with insulation.

Mineral wool, sewn on both sides with an OSB board, is very effective, SIP manufacturing panels inside there is polystyrene glued with OSB boards in factory conditions. In addition, a layer of vapor barrier is laid inside and windproofing on the outside. The inside of the entire structure is usually sheathed with ordinary plasterboard, and the outside with any material you like. finishing material: siding, decorative bricks or plaster.

The thickness of such a wall is 15 cm. All communications are laid inside the hollow walls. If it is necessary to repair or replace them, it is enough to remove one panel and then simply insert it into place. It is clear that such a house is very light and does not require an overly heavy foundation. During its construction, already prepared and adjusted blanks are used, which makes heavy equipment unnecessary. It is built completely from scratch in 2–3 months by only 3–4 workers.

So difficult or not?

Many sites claim that it is easy to build yourself. It’s entirely possible to do it yourself, but it won’t be easy. The construction of a frame house is a high-tech process that requires certain knowledge and very precise adherence to technological requirements. At its core, this is the construction of a thermos. The jambs will result in a quick cooling of the house, drafts or dampness.

A little excursion

The construction of frame houses began in the late 20s of the last century in the USA, where it is the most popular type in modern conditions. Some of the houses built then are still suitable for living, isn’t this an indicator that, if the technology is followed, they can be long-lived, along with stone ones. Today, the technology of a wooden frame house is widespread in the Scandinavian countries, in particular in Finland, as well as in Canada, where it is no warmer than in the Siberian regions of Russia.

The construction of frame houses began in the late 20s of the last century in the USA, where it is the most popular type in modern conditions. Some of the houses built then are still suitable for living, isn’t this an indicator that, if the technology is followed, they can be long-lived, along with stone ones. Today, the technology of a wooden frame house is widespread in the Scandinavian countries, in particular in Finland, as well as in Canada, where it is no warmer than in the Siberian regions of Russia.

About our realities

Now a little about how frame houses stand in Russia. In practice, the construction of frame houses is the process of erecting half-finished structures in the right place. Today, in the vast expanses of Russia, factories for the production of SIP panels, frames and other necessary parts of the house are being built at a rapid pace. Many architectural bureaus offer their services for designing panel cottages. And no matter how many myths walk across the expanses of this great country, frame houses are being built, and construction is picking up pace .

One-story frame houses for permanent residence projects

Here we consider frame houses suitable for permanent residence, and they can be quite roughly divided into several categories:

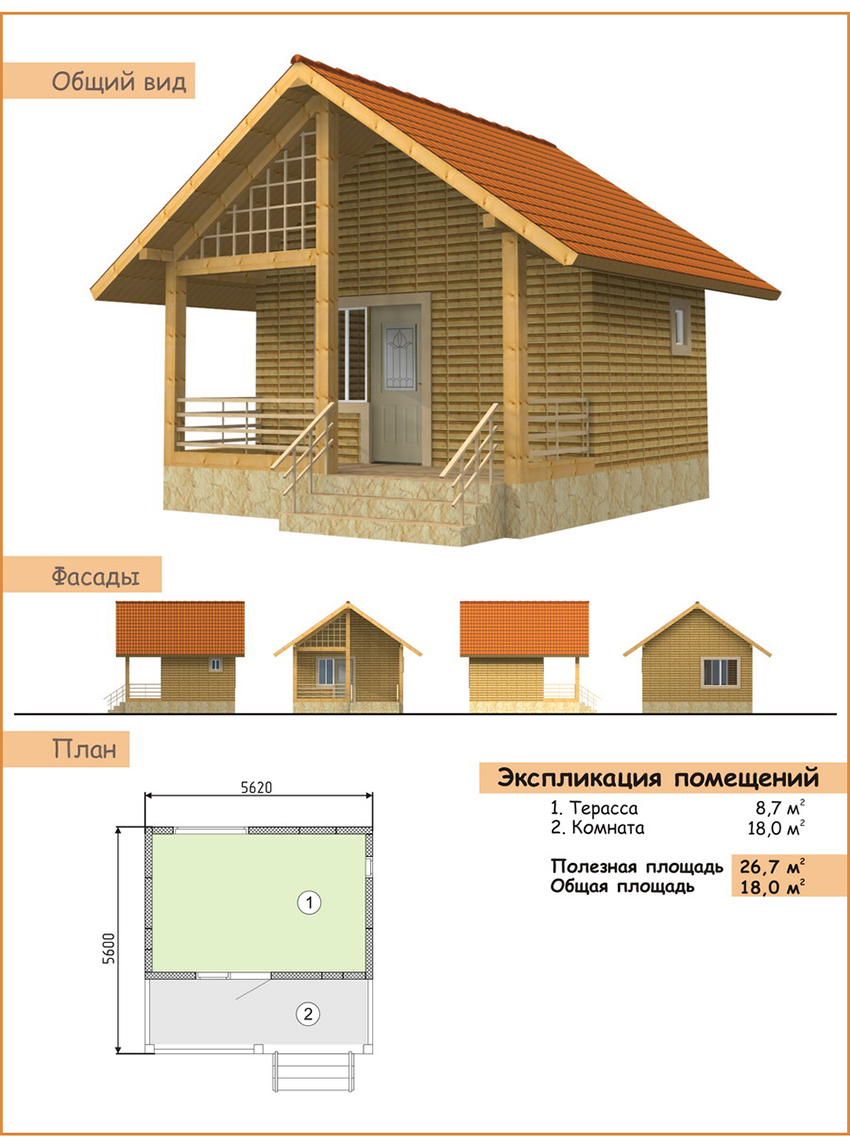

Projects of frame houses up to 50 sq. m.

Assumed to be small, usually insulated mineral wool. This house is designed to accommodate no more than three people and is very convenient for a small family.

The house has a boiler room with an entrance from the street, and, at the request of the customer, can include a carport. The terrace options are as varied as external finishing. Typically, several façade options and projects with and without a basement are offered.

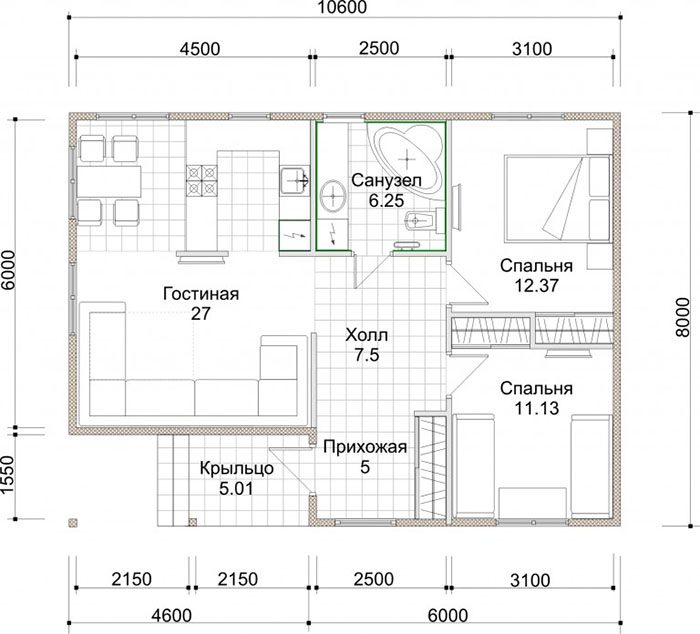

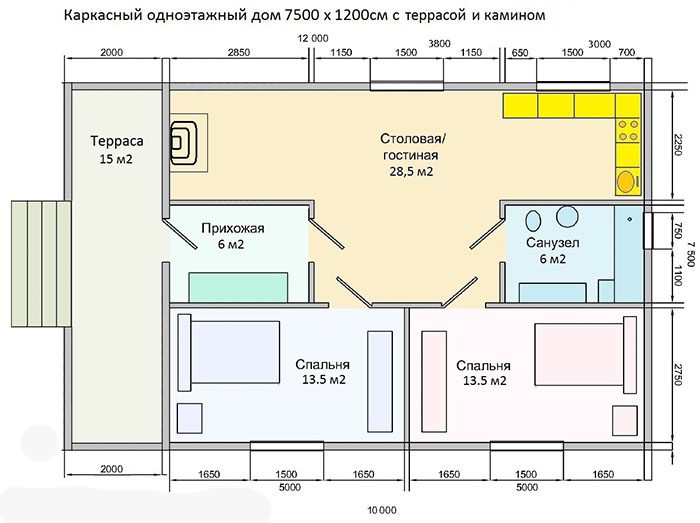

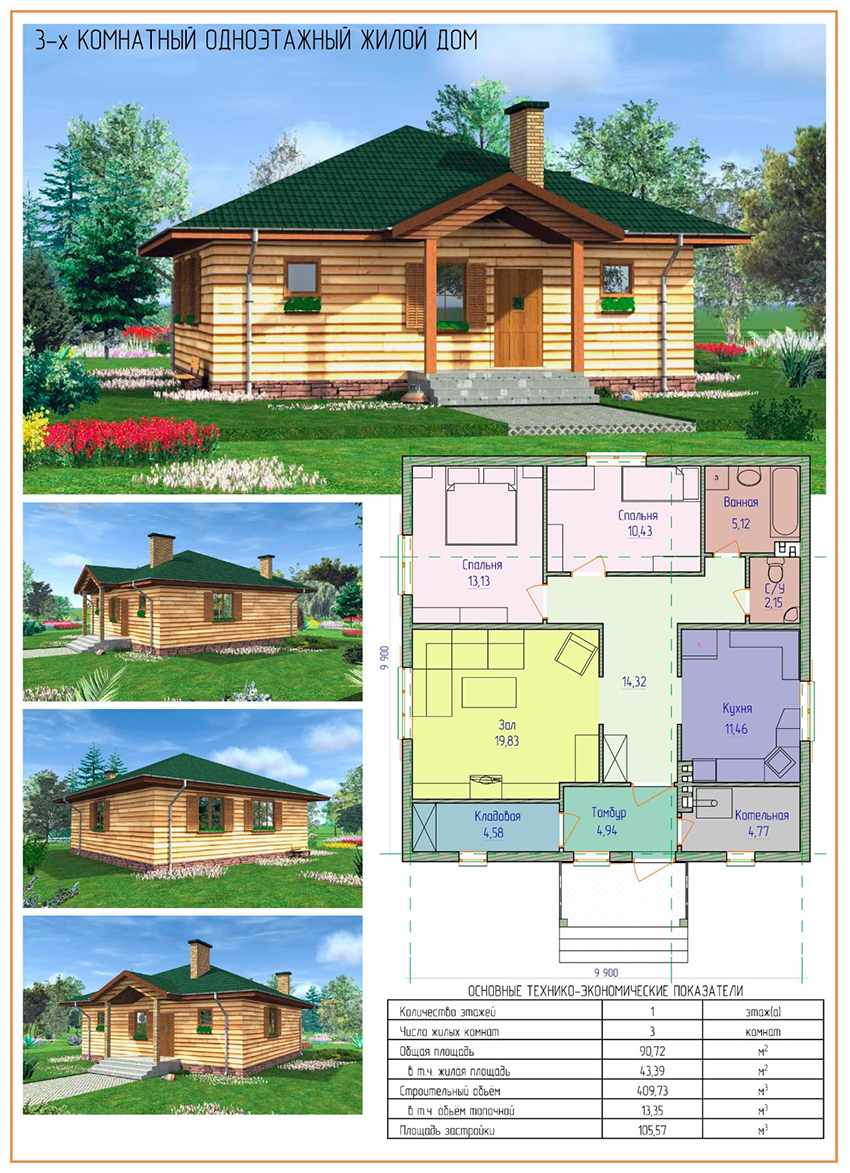

Projects of frame houses 50–100 sq. m.

As a rule, they do not exceed one floor, have a boiler room and a carport or, at the customer’s request, a garage. There are usually two bedrooms and a living room; the house is designed to accommodate no more than four people. Projects with and without a basement are possible. All communications typical for a city apartment are provided in this house.

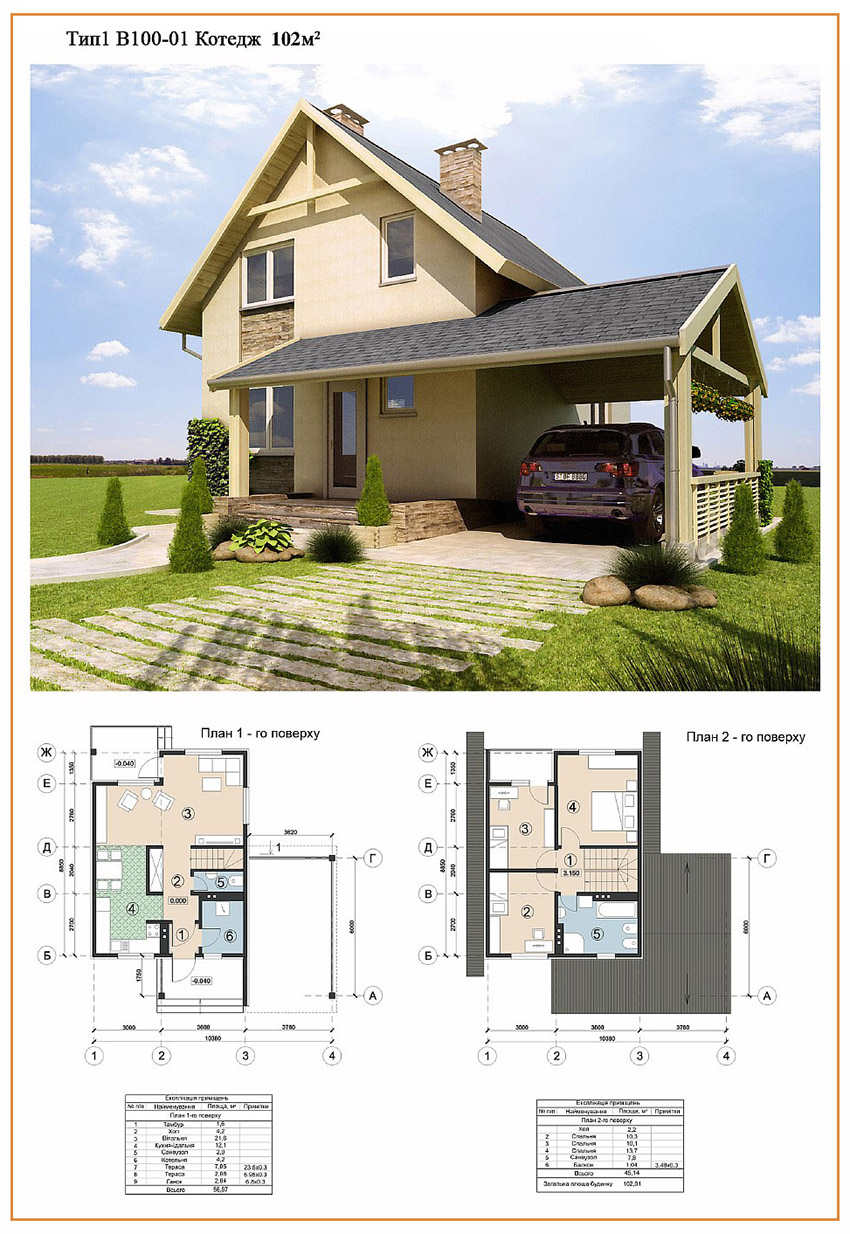

Projects of frame houses 100–150 sq. m.

They offer both one-story and two-story buildings. The floors will be made of reinforced beams and weighted SIP panels. Most often, such projects provide for the presence of common rooms on the ground floor: living room, hallway, kitchen, dining room, and on the second floor three bedrooms and a hall. Each floor has bathrooms and restrooms; at the request of the customer, a sauna can be installed. There is a boiler room and a carport or garage. Basement at customer's request. It is possible to design a bay window, terrace, balcony. Several façade options.

Projects of frame houses 150–200 sq. m.

In addition to all the possibilities described in smaller houses, it is also proposed to build a third floor or attic. Such houses look very impressive in the version of two floors and an attic. The maximum number of people recommended for accommodation is 7.

Projects of frame houses from 200 sq. m.

They provide a wide field for the architect’s creativity and allow one to envision both two- and three-story options, as well as simply spacious one-story buildings. Here it is possible to satisfy any whim of the customer.

About some advantages of frame houses

- Proponents of frame houses call the pace of construction one of the main advantages. Most of the work is done within the walls of the materials manufacturing plant, where they are cut and adjusted to fit the project. In this case, all components are treated with special antibacterial and anti-flammable mixtures. This allows you to assemble a house of 100–200 square meters. m. on a site allocated for construction in 14–21 working days.

- Many people call the low-budget nature of the project a big plus. But we must honestly admit that if all the rules are followed and high quality materials are used, square meter houses up to 50 sq. m. will cost from 90 S, houses from 100 sq. m. m. – from 85 S and from 200 sq. m. - more than 80 S. At the same time brick house the same size will cost 20–25% more.

- The construction of a frame house does not require heavy equipment and a large number of workers. It can be assembled by 2-3 people. Sami wooden floors and the panels are light and delivering them is not difficult.

- As for the house itself, the opportunity to hide all communications inside the walls will be a big plus.

- The house is light and will not shrink, which will allow you to immediately begin interior finishing work.

- If it is necessary to replace or adjust communications, you do not need to drill into the walls; just remove one panel. You can also inspect other internal components of the house. Rating: 3.9 8 votes

In our catalog in the photographs you can see a variety of options for frame-panel houses, cottages and summer houses. Many clients want to order our standard projects without making changes. Construction on typical projects proceeds quickly; our specialists have already built each of them more than once. You can find projects of one-story frame houses with which we work in our catalog.

Many people know that frame houses are those in which the role of a load-bearing element is performed by a frame made of timber or individual metal products. But not everyone knows what a frame-panel house is.

In such a building, a load-bearing frame is also present, but it is erected not from individual elements, but from entire panels - walls, facade elements and other large blocks. The panels are assembled at the manufacturing plant and sent to the construction site in assembled form. All that remains for specialists is to correctly fasten the panels to the frame.

Using shields instead of individual small components has advantages:

- building a house is easier and faster - builders need to fit large elements to each other, and not many small ones;

- Almost always such houses are built “turnkey”, saving the nerves and money of the future owner;

- The construction site area is not cluttered with large volumes of materials, which is very important if land plot small, and there is nowhere to put the things necessary for construction;

- heat loss is low, because the design of the shields involves multi-layering.

Contact us for the one-story frame house of your dreams!

We have been building inexpensive frame one-story turnkey houses for more than 10 years. We have many completed projects under our belt, both typical ones shown in the photo and unique ones. The price for objects of different complexity varies, but is always agreed upon in advance.

We build facilities in Pestovo, throughout the Moscow region, in Moscow itself and the vast Moscow region. You can buy a project from us or order the construction of housing at any time, consultants will always explain unclear points, construction will begin and end within the agreed time frame.

We recommend buying a one-story frame house - it will become a good dacha, summer house or place for permanent residence. It can be built inexpensively, unlike brick or wooden houses, but on operational characteristics he is not inferior to them.

Projects of one-story frame houses are successfully used in the construction of such private buildings as: residential buildings on summer cottages, small but functional guest and summer houses, “winter” options. The popularity of one-story frame houses for permanent residence or “seasonal” visits is due to:

- A simplified construction process, and, as a result, significantly “shortened” deadlines.

- No need for special equipment.

- The lightness of a “box” at home. The building does not shrink, it does not require a capital foundation, you can get by with an inexpensive and “pre-fabricated” option.

- Variability of layouts with the same footage.

- The ergonomics of the space used, despite its compactness.

- Simple installation of engineering systems.

- Economical and less labor-intensive, compared to houses with two or more floors, maintenance of the building.

- The resistance of one-story frame houses to soil shifts, which is important for seismically unstable areas.

- Significantly reduced final cost of construction due to the minimized amount of work and wisely selected materials.

In addition to the standard residential premises for a one-story frame house (a kitchen, most often combined with a living room, the required number of bedrooms, a bathroom), it is possible to add a spacious terrace, a closed veranda, and a spacious garage to the project. One-story project frame house is the best option for independent construction of your own home. We are ready to help in all matters: from detailed calculations of the project and making appropriate changes to assistance in the delivery of house kits and the construction of a reliable, durable, comfortable home.

Advantages of our one-story frame houses

Projects of one-story frame houses from "Karkas-Komplekt" - right choice! Construction of one-story frame houses with us means saving time, money and comprehensive support at any stage.

- There is no reason to waste time designing from scratch. One-story frame houses are a ready-made and simple solution!

- In the catalog of projects, you yourself choose the design of your future home and its layout.

- The final price of the project depends on the complexity of the configuration and the scope of work. One-story turnkey frame houses are inexpensive when compared with traditional options (for example, buildings made of brick or timber).

- If necessary, it is possible to modify the standard design of a one-story frame house to suit the individual tastes of the buyer.

- Depending on the purpose of the one-story frame house, you can choose one of the types of house kits: “economy”, “comfort”, “Finnish”. The house kit is included in the project package; If you need it, we’ll bring it and assemble it ourselves!

- In the production of frame houses we use modern, environmentally friendly materials.

- We provide quality control: from design to production of necessary components, assembly and finishing of the house.

- We provide a full package of documents: text materials, detailed instructions, drawings, communications wiring diagrams, documents for approval of construction and registration of construction.

- IC "Karkas-Komplekt" is not just a team, but a real team. We are united by experience, dedication to our work and the desire to provide high-quality and affordable frame one-story houses"turnkey" for everyone who plans to acquire their own home.

Have you decided to buy a one-story frame house? Do you need detailed advice on cost, timing, materials? Contact us! We will help you choose a project based on your budget, your individual wishes and preferences!

Construction by frame technology will allow you to become the owner of a comfortable home on a country plot in just 1–1.5 months. In most respects, buildings built on a load-bearing frame made of softwood are not inferior to brick houses.

Initially, the technology was developed for use in Canada and Scandinavia. The level of thermal insulation provided by multilayer insulated walls is optimal in the conditions of central Russia. Most projects provide their own boiler room and fireplace to maintain a comfortable temperature during the cold season.

Range architectural solutions, which can be implemented on the basis of frame technology, is practically unlimited. You can plan the perfect space for your family for a summer vacation or permanent residence. At the same time, one-story frame houses are at least 3 times lighter than cottages of comparable area made of brick. This significantly expands the architect’s capabilities when designing buildings that will be erected on difficult soils.

Advantages of one-story frame houses:

- Reducing the design load on the foundation and soil allows you to build reliable home for several generations with a general reduction in material consumption, land and installation work. The savings remain significant even when instead pile-screw foundation, for the construction one-story house used on clay soil strip foundation or monolithic reinforced slab.

- A space in which you feel comfortable: The useful area of a one-story house can be no less than that of a 2-story cottage. You can order the construction of a full-fledged country mansion with a garage, a large terrace that can be accessed directly from the living room, or a spacious veranda.

- Safety for everyone: stairs are a high-risk area for small children and the elderly. When it does not take up free space from living rooms, you can develop more interesting layout options that are comfortable and safe for each family member.

- Assembly in record short time: To build a frame house in most cases it is not necessary to use special equipment; all work can be completed by one team of professional builders in less than 1 month.

- No shrinkage effect allows you to start interior decoration and interior design as soon as construction work is completed on the site.