Exterior house cladding materials. How to sheathe the outside of a frame house.

Cladding a private house is an important final stage of construction. And at this stage, most developers choose the cheapest finishing for the facade of the house. Why is this happening?

On the one hand, the cladding of your own home must meet all the standards of reliability and aesthetics, and on the other hand, it is obvious that it is not worth throwing away a large amount of money, without guarantees that such a decision will be fully justified.

Only one family in ten can afford to choose any finishing option, regardless of its high cost. The remaining 9 families, which is 90 percent of developers, are trying to save as much as possible and choose the most cheap way facade finishing, sometimes even to the detriment of functionality and visual beauty.

Going to extremes will also not be the best option. If we stop at the very budget option, then you can lose on the performance characteristics of the facing material. As a result, it will not withstand adverse conditions well natural conditions such as: wind, frost, snow, rain. There is a saying about this: “the miser pays twice.”

Cheap cladding of the facade of a house is quite possible, you just need to choose the best option, the cheaper it is to finish the facade of a house, which takes into account all the most best characteristics material. In order to competently decorate your home, while saving a lot of money, you should decide on the main aspects of choosing the material. If you purchase a good and reliable finishing material, then this is already 50% success.

Selection of facing material

When choosing, you need to know that they mainly pay attention to aesthetic characteristics. There is no doubt that the “beauty” of such cladding is a very subjective question, because it depends on the individual preferences of each owner.

Nevertheless, there are parameters of facing materials that will not go unnoticed in any case. You can choose the most cheap material for the facade, you just need to take a closer look at criteria such as:

- availability of color lines provided by the manufacturer of the façade material;

- parameters of resistance to fading and external defects;

- what raw materials the finishing material is made from, including its environmental friendliness.

Another important criterion is the durability of the facade. When choosing inexpensive material you need to make sure it is durable so that it does not have to be replaced every year. Because cheap cladding of the facade of a house, initially low-cost, can result in annual renovations or repairs, which will hurt the budget of the thrifty owner.

Total cost of installation of facade materials

How to get a brick cheaply? Buy good brick with minor defects. This can be done at the factory or you can buy leftovers from the dealer's warehouse.

By choosing this inexpensive facing material, you don’t have to worry that the facade of the house will fade. The only downside is that there is a chance of efflorescence.

Ceramic tile

The prices for the material are quite low, and the tile itself is a reliable material, so facing the house with ceramic bricks will fully justify the investment. Installing tiles, as a rule, takes a long time, but if you have the necessary information on installing facing bricks, you can complete the work in the range of 5 to 8 weeks.

Facade tinted primer

Facade primer is a material that has become very popular in finishing facades in the shortest possible time. If the facade of the house is pre-plastered, then it is best to use a deep penetration primer for cladding private housing. For, which is impregnated with an antiseptic to avoid the appearance of harmful bugs.

As you know, the appearance of a house should create a feeling of comfort and coziness. Therefore, you should not save too much, as this may adversely affect the integrity of the house in the future.

Thermal panels

Another economical option is thermal panels. A façade made of this material has many advantages, since dense polystyrene foam is used in its manufacture, which contributes to excellent thermal insulation. In the summer, the house will be cool, and in the winter, heat will not escape from the house.

Installation of thermal panels is carried out using ordinary self-tapping screws, so almost everyone can carry out the installation themselves in the shortest possible time.

Another worthy advantage is that the panels can be installed at any time of the year, since the material has increased strength.

A natural stone

Facing the façade with natural stone cannot be considered an economical option at all. However, where it is possible to obtain this facade material virtually free of charge, this will be the cheapest way to finish the facade.

Where can I get natural stone for almost free? Drive to the nearest quarry with your own trailer, or try to buy a stone with minor defects from a dealer.

You can also purchase the remains of stone after facing large houses. If your house is small, then the remains from the cladding of a large house will be enough for you to make.

A house made with this particular material will look very beautiful. The stone will give it a very original and unique aesthetic look. The technology of facing a house with stone is very simple.

First you need to prepare the base. This stage includes leveling the surface of the base using ordinary plaster. Then you need to install extruded polystyrene foam on its surface. It is attached using self-tapping screws or dowels. Next, you need to apply an acrylic primer to the surface of the slabs. Are running out preparatory work the fact that a steel mesh is installed on the wall.

Then you need to decide on the mosaic that will be made of stone. You can draw a plan in advance so as not to make mistakes during the work process. You should try very hard, since the appearance of the facade depends on this. Next, you need to rub the seams and joints with mortar. After completing the work, experts advise applying a special varnish to the stone to make the color of the material brighter and more saturated.

Also, in this way you can protect the walls from wind, rain and frost. Facing the facade with natural stone will be the most reliable and, at the same time,...

Conclusion. The cheapest finishing of the facade of a house is possible if you have chosen the cheapest material for the facade or the material whose installation can save money.

Also, if you have the opportunity to get expensive cladding material very cheaply, it will give you the opportunity to make an expensive house façade for cheap.

See if you have the opportunity to remove substandard natural stone or decorative brick with defects. For these materials, small defects are not critical, but such a facade will be installed for centuries and will look very impressive.

-

So, you choose the materials that can be used to cover the facade of the house. Which material is better? Photos of different facades with different materials used will help you solve this... -

The original decoration of the facade of the house with stone-effect panels, the photo of which you see on this page, allows you to obtain a decorative and respectable facade at the lowest cost. Besides,...

The saying “You meet people by their clothes” applies not only to people, but also to their homes. Therefore, the facade of the house plays an important role for its owners, since...

Wooden house for many individual developers is the highest priority: it is environmentally friendly, it creates the most favorable atmosphere for human health, it heats up quickly and retains heat well. But wooden walls for protection from adverse influences, insulation and decoration, it is often required plating.

When choosing wall material for external façade cladding For your home, you need to know the pros and cons of each of the options on the market today. It is important that the chosen material is not only beautiful, but also practical and can protect your home from all adversity for a long time.

Options for sheathing wooden house outside mass - from lining to brickwork, and the possible outcome may be limited only by money and your imagination.

New home external cladding will give a finished appearance, and will improve the protection of the old structure from the negative effects of the environment and remove visible defects.

For outdoor wall cladding A wide range of materials are used, including machined steel, aluminum, wood, stone, vinyl and PVC coating. External cladding of windows, doors, roofs - any areas at risk of moisture penetration is carried out.

Lining- today the simplest, most convenient, easily accessible and cheapest type of material for exterior finishing wooden house. Anyone who has ever held a hammer or saw in their hands and accurately measures the distance with a ruler can sheathe the outside of a house with clapboards.

Lining- today the simplest, most convenient, easily accessible and cheapest type of material for exterior finishing wooden house. Anyone who has ever held a hammer or saw in their hands and accurately measures the distance with a ruler can sheathe the outside of a house with clapboards.

Lining was originally the name given to the wooden slats that were used to cover transport cars. So this name stuck to it.

Today, it is customary to call selected, specially treated wood clapboard. Simply put, lining is a cladding board.  The lining is produced in "tongue" and "quarter" and is divided into one and a half meter, six meter and three meter lengths. On opposite sides of the lining there is a groove and a ridge of equal size.

The lining is produced in "tongue" and "quarter" and is divided into one and a half meter, six meter and three meter lengths. On opposite sides of the lining there is a groove and a ridge of equal size.

The humidity of such a board should not be more than 10-15%. If the moisture content of the boards is higher, then after finishing the walls, in the process of further drying, the density of the connections between the boards will change and cracks will form, which will negatively affect the appearance of the house.  The house is clad with clapboard from bottom to top. The board is nailed with small nails to the wall with the ridge up, after which the next one is put on the ridge of the bottom board from above with a groove. Using small wooden wedges, the top board is pressed against the bottom board along the edges; if the board is long, in the middle. Then the top board is nailed down and the wedges are removed. And so on all the way to the roof.

The house is clad with clapboard from bottom to top. The board is nailed with small nails to the wall with the ridge up, after which the next one is put on the ridge of the bottom board from above with a groove. Using small wooden wedges, the top board is pressed against the bottom board along the edges; if the board is long, in the middle. Then the top board is nailed down and the wedges are removed. And so on all the way to the roof.

Finishing with wooden clapboard looks somewhat old-fashioned, but is environmentally friendly and vapor-permeable. Installing wooden lining is not difficult. After installation, impregnation or painting is required.  Wood is a material familiar to us all, environmentally friendly and relatively inexpensive for cladding a house ($4-7 per sq.m.). However, the initially neat appearance gradually ceases to be so.

Wood is a material familiar to us all, environmentally friendly and relatively inexpensive for cladding a house ($4-7 per sq.m.). However, the initially neat appearance gradually ceases to be so.

Wood does not withstand weather conditions and the appetite of insects as well and, like any wooden covering, is not able to withstand fire. Moreover, wood paneling requires annual maintenance, spending a certain amount of time and money. Some types finishing works cannot be carried out year-round, for example, at temperatures below zero.  In contrast to the lining can be imitation timber, which is a spruce or pine board laid out in horizontal position without visible intermediate grooves.

In contrast to the lining can be imitation timber, which is a spruce or pine board laid out in horizontal position without visible intermediate grooves.

When laying such a board, the surface turns out smooth and beautiful. It is not without reason that imitation timber is used not only for the exterior decoration of a wooden house, but also for cladding bricks, blocks, logs and other materials.

It is worth noting that the spruce board used for exterior cladding of the house goes well with metal and stone. This combination gives the house a sophisticated sophistication and makes it stand out from the rest.

IN Lately began to be used frequently wood-polymer lining, which combines the best qualities of wooden lining and polymer materials.

It is moisture resistant, does not rot, does not require frequent maintenance, and can last for decades.

Block house, as it is commonly called today, is a board made of coniferous trees; this material has a semicircular pattern on the front side.

Block house, as it is commonly called today, is a board made of coniferous trees; this material has a semicircular pattern on the front side.

The block house is most often used for cladding the exterior of a house. frame type. But even today it is not uncommon to see the use of rounded boards when finishing the facade of a wooden house.  Combination wooden beam with a block house creates an elegant appearance that will please not only its owners, but also guests, as well as all temporary visitors.

Combination wooden beam with a block house creates an elegant appearance that will please not only its owners, but also guests, as well as all temporary visitors.

It must be emphasized that the block house is not afraid of sudden changes in temperature and can withstand frosts and hot summer days.

Therefore, regardless of what region you live in, if the question arises of how to cover the outside of a wooden house, you can safely choose a block house as one of the ways to decorate the facade of your own home.

Siding– these are separate panels that are very conveniently fastened together.

Externally, siding is similar to plank cladding. Each panel has a snap lock and perforated nail edge. Siding strips come in different sizes. The length, as a rule, varies from 2 to 6 meters, width 10-30 cm, thickness up to 10 mm.  Manufacturers offer different kinds siding - basement, ceramic, steel, wood, cement, aluminum, copper.

Manufacturers offer different kinds siding - basement, ceramic, steel, wood, cement, aluminum, copper.

Siding has gained enormous popularity today. It is used for cladding private houses, office buildings, commercial premises, etc. The material has won such recognition due to its qualities - durability, strength, attractive and neat appearance.

The siding profile is made in two versions: “herringbone” (single fracture) or “ship plank” (double). This does not affect the quality of the material in any way, and the profile is selected only based on personal preferences.

The texture of siding most often imitates natural wood. To protect against impacts, scratches and corrosion, a special polymer coating or paint is used.  Siding retains its quality and original appearance for several decades. It perfectly protects the building from atmospheric agents.

Siding retains its quality and original appearance for several decades. It perfectly protects the building from atmospheric agents.

This is a very lightweight, easy-to-use material that looks great in any landscape. In addition, siding is environmentally friendly and easy to maintain. It is easy to clean and does not require periodic painting, unlike wood materials.

All types of siding for cladding a house are very easy to install and you can cladding the building yourself. Installation of siding does not require special skills, including careful preparation of the wall surface. On the contrary, it helps to hide many unevenness and other flaws.

Vinyl siding

made from polyvinyl chloride. It consists of solid strips, which are also called panels. Each panel is monolithic sheet, which is given the desired shape.  Vinyl siding does not crack, dry out, rot, and is not of any interest to insects, unlike wood materials. Another advantage of siding is that it does not support the combustion process, but simply melts under the influence of high temperatures.

Vinyl siding does not crack, dry out, rot, and is not of any interest to insects, unlike wood materials. Another advantage of siding is that it does not support the combustion process, but simply melts under the influence of high temperatures.

PVC panels are used both for the construction of new buildings and for finishing old houses. Often, simultaneously with the installation of siding, the building is insulated, since it is very convenient to install insulation into the sheathing space.

Vinyl siding is available standard sizes:

- length – 3000 mm, 3660 mm, 3730 mm, 3850 mm;

- width – 205 mm and 255 mm;

- thickness – 1.1 mm and 1.2 mm.

Advantages of PVC panels:

- low level of flammability;

- environmental Safety;  - resistance to weather conditions and chemical substances. It has proven itself well in conditions of high humidity and moderate acidic or alkaline environments. Does not crack, does not warp in the sun and does not rot;

- resistance to weather conditions and chemical substances. It has proven itself well in conditions of high humidity and moderate acidic or alkaline environments. Does not crack, does not warp in the sun and does not rot;

- operating temperature range 0t -50 to +50 degrees. Under such conditions, it does not burst and does not change the original shade;

- ease of operation: easy to clean with a hose and does not require additional painting during the entire service life; - huge selection of colors and shades;

- does not interfere with the ventilation of the house, as it does not seal the walls tightly;  - holes in the lower edges of the panels prevent condensation from accumulating. This protects the insulation material and wooden structural elements from rotting;

- holes in the lower edges of the panels prevent condensation from accumulating. This protects the insulation material and wooden structural elements from rotting;

- thanks to the possibility of insulation, it saves money on heating the house;

- low price compared to other types of facing materials;

- high reliability, which avoids expensive and energy-consuming repair work;

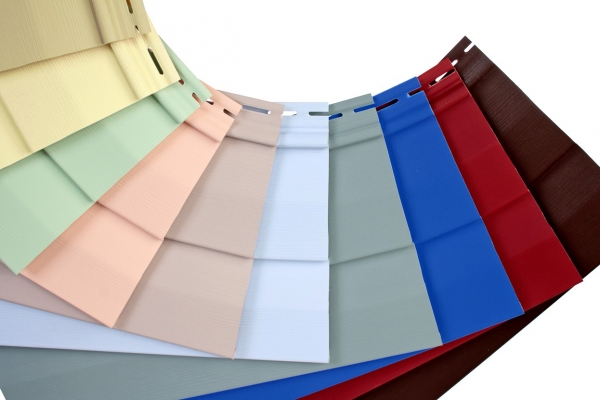

- the texture of the outer surface of the panels can be smooth or rough, imitating natural wood.  Today there are about 15-20 options on the market siding colors. All of them can be divided into three main groups:

Today there are about 15-20 options on the market siding colors. All of them can be divided into three main groups:

- white;

- pastel;

- colored.

Most often you can find siding in pastel shades. This type is optimal in terms of price, visual and operational qualities.

Siding in bright colors also has a very attractive appearance. But at the same time it costs twice as much as the usual material.

This increase in price is due to the need to add expensive substances that prevent sunburn.

In fact, lining is also siding, but still, returning to the origins of the emergence of this particular trend in the decoration of house facades, siding is a finishing material made of plastic that imitates a plank covering. Therefore, today the most popular type is considered to be covering a wooden house with “wood” siding.

There are two ways to install PVC panels: horizontal and vertical.

Vertical siding used relatively recently. In another way it is called soffit.

Soffit used for external decoration.

Soffit used for external decoration.

Soffits in construction industry are called panels that are designed for covering various horizontal surfaces facing down (eaves, overhangs, ceilings in open rooms, etc.).

One of their main functions, oddly enough, is not external beauty or giving the building a finished look, but providing ventilation of the under-roof space, which can significantly increase the service life of the roof.

If you need not only to beautifully arrange the roof surface, but also to ensure excellent ventilation of the under-roof space to prevent the appearance of dampness and mold, then you should hem the eaves and gable overhangs with siding - soffit.

This is a panel, it is attached to the box along the edge of the roof, which gives it a complete aesthetic appearance. The panels are joined together with a locking connection, this allows you to hide their fastenings.  In fact, it is the same siding or lining, but it is intended for decorating the ceiling and is called a beautiful Italian word, which means ceiling.

In fact, it is the same siding or lining, but it is intended for decorating the ceiling and is called a beautiful Italian word, which means ceiling.

A significant difference between soffits used outdoors and other types decorative panels, is the presence of perforation. It ensures free passage of air through them, which protects materials from mold, dampness and fungal attack.

There are both without perforation - for interior decoration, and with perforation - for outdoor use.

Wood siding.

Differently wood siding called glued lining.  The panels are made from wood fibers compressed under high pressure and high temperature. For better connection special resins are added to the fibers with each other.

The panels are made from wood fibers compressed under high pressure and high temperature. For better connection special resins are added to the fibers with each other.

For reliable protection from external influences, wooden siding must be coated with several layers of varnish or paint. Recently, wooden siding has been used less and less. And with the advent of new materials, it completely fades into the background.

This is due to the following disadvantages of this material:

- high price;

- short service life;

- tendency to ignite;

- high moisture absorption;

- the need for tinting and impregnation throughout the entire service life in order to avoid major repairs for as long as possible.

Basement siding- a type of vinyl panels that are used specifically for finishing the base. This siding has higher strength characteristics.

The basement is exposed to destructive factors much more than the rest of the house. In summer it gets very hot from sun rays and asphalt pavement. And in winter it is in conditions of high humidity due to sticking snowdrifts.

There is much more variety in basement siding designs than with simple vinyl panels. From a variety of colors and textures, you can always choose the most optimal option. Most often, basement siding models imitate alternative natural facing materials: wood, stone, brick, etc. ![]() Stone-look facade panels do not require maintenance, repairs, etc.

Stone-look facade panels do not require maintenance, repairs, etc.

Basement siding is resistant to any chemicals, mechanical damage, easy to clean. Cladding with stone-look facade panels, like siding, is done on a frame attached to the walls. With the help of basement siding imitated with stone or granite, it is possible to create a full-fledged ventilated facade - using a layer of insulation and a ventilated gap.

The panels are used for finishing both external and internal surfaces. Basement siding is used for:

- covering the walls of the house and the foundation;

- creating a building facade with a ventilation system and a layer of insulation;

- creating original designs for garages, bathhouses, fences, gazebos, etc.;

- decorating walls inside premises for various purposes.

Among the many advantages of basement siding, the most important are:

- moisture resistance (makes it possible to use in saunas and swimming pools);

- lightness (perfect for covering ceilings);

- speed and ease of installation (allows it to be used for the assembly and reconstruction of temporary exhibition stands).

Metal siding. It is a lightweight long panel of various widths: 120, 300 and 550 mm. Each panel has locks with which they are fastened together.

It is a lightweight long panel of various widths: 120, 300 and 550 mm. Each panel has locks with which they are fastened together.

The most common material is galvanized steel. A coating is applied to the surface. One of the coating options is a polymer material - polyester, plastisol, pural. In this case, the color choice is limited to only six to eight shades.

Another type is painting using a special powder. With this method, the color range is much more diverse.

Metal siding has advantages over vinyl:

- increased strength characteristics;  - durability;

- durability;

- resistance to sudden temperature changes;

- color fastness;

- non-flammability.

In addition, metal siding has hidden fastenings, which significantly improves the appearance of the structure. This is especially important when it comes to facade cladding.

The undeniable advantages of metal siding are its fire resistance and durability.

The color range of metal siding is varied, although too bright colors focus attention on the “artificiality” of the material, but, as they say, it depends on taste and color.

Metal siding has increased strength (galvanized steel at the core, then a passivated layer and a primer layer), and is absolutely not attractive to insects. It does not fade in the sun, so it retains its color throughout its entire service life (from 50 years). But with a strong impact, the surface may be deformed and dents will remain on it.

In addition to periodic washing, metal siding requires additional care, for example, applying special protective coatings due to the risk of corrosion. And it costs much more than wood or vinyl cladding ($12-25 per sq.m.).

A significant disadvantage of this type of cladding is that metal transmits heat more than other types of cladding materials, so when installing metal siding, the house needs additional insulating material to prevent cold in winter or excessive heat in summer.

It is also important to remember that metal siding panels are quite heavy and require a certain margin load-bearing structure buildings, so may not be suitable for every home.

Aluminum siding. This material is suitable for finishing residential premises, offices, industrial buildings. Due to the lightness of the panels (only 1.7 kg per sq.m.), safe use in multi-story buildings is possible.

Aluminum siding. This material is suitable for finishing residential premises, offices, industrial buildings. Due to the lightness of the panels (only 1.7 kg per sq.m.), safe use in multi-story buildings is possible.

This type of siding is ideal in situations where you need to quickly bring the building into decent shape. Behind short term you can update the walls and ceilings of the building, while avoiding complex and expensive repairs.

Corrugated sheet. The corrugated sheet is made from galvanized or steel profiled sheet, which is covered with a protective layer. It is used as wall decoration, for roofing, for the manufacture of fences and ceilings. In appearance, the corrugated sheet resembles a slate sheet.  The advantages of corrugated sheeting are: strength, durability, cost-effectiveness, a wide range of colors and ease of installation.

The advantages of corrugated sheeting are: strength, durability, cost-effectiveness, a wide range of colors and ease of installation.

Corrugated wall or fence sheeting does not withstand excessive loads and is mainly used as temporary fencing.

Corrugated roofing has much higher strength. It is used for cladding rooms, roofing and making fences.

Load-bearing corrugated sheeting is the strongest of all types of corrugated sheeting. This type of corrugated sheeting can withstand fairly high loads.

To prevent corrosion and resist chemical attack, the corrugated sheet is coated with polymer-based compounds. This significantly extends the service life of the corrugated sheet.

When using a finishing material such as corrugated sheets, it can be modified for specific functions. It is possible to add roundings, grooves and various specific devices.

In terms of speed of installation, corrugated sheeting differs from siding in much shorter times, due to the fact that the corrugated sheet has a much greater length compared to siding panels.

The advantage of siding is its longer service life, which can be about 50 years. It is not susceptible to corrosion and insect pests. But with bright rich colors, the panels fade very quickly in the sun.  Corrugated sheeting retains its color much longer; the disadvantage is that the metal is susceptible to corrosion. Even if it is treated with an anti-corrosion coating, its service life is about 15 years.

Corrugated sheeting retains its color much longer; the disadvantage is that the metal is susceptible to corrosion. Even if it is treated with an anti-corrosion coating, its service life is about 15 years.

In addition to lower cost, the advantages of corrugated sheeting include the preservation of its inherent properties under all weather and climatic conditions.

Corrugated sheeting is practically non-flammable, and due to its low weight it does not exert excessive pressure on floors and supports. Covering a building with siding allows you to save much more heat, whereas when using corrugated sheets, it is advisable to use an additional layer of insulation.

Corrugated metal sheet has a smooth surface, low cost and durability, but does not allow air to pass through. In this regard, it is not suitable for cladding buildings with a frame-panel construction. Can only be used as a material for cladding ventilated facades.

Ceramic siding- a fairly new invention for cladding and decorating the facade of a building. This best material for finishing in the middle price category.

Developments regarding ceramic siding belong to practical Japanese specialists. They try to use everything that nature provides with benefit and a rational approach.

Ceramics for siding is a mixture of clay interspersed with other natural materials. The panels are environmentally friendly, hypoallergenic and fireproof.

The quality of ceramic cladding can easily be compared with high-strength ceramic tiles.

Cement siding Cement siding contains cellulose fiber and cement itself. At the final stage of manufacturing such panels, a texture imitating wood is applied to the surface using a special method.

Cement siding contains cellulose fiber and cement itself. At the final stage of manufacturing such panels, a texture imitating wood is applied to the surface using a special method.

Among the many advantages of cement siding are the following:

- good resistance to temperature changes, precipitation, wind, ultraviolet rays, mold, mildew;

- cement siding is not exposed to insects;

- allows you to quickly update an existing building, give it a fresh look, decorate the facade, align the walls;

- possibility of use in buildings with increased fire safety requirements due to high fire resistance qualities;

- long service life;

- good color fastness;

- ease of installation and ease of maintenance.

![]() Compared to other types, the following disadvantages can be mentioned:

Compared to other types, the following disadvantages can be mentioned:

- heavy weight, for which the sheathing must be more durable;

- high price;

- inconvenience and difficulty during cutting: it is necessary to use protective equipment (masks or respirators) to avoid getting silica dust in the face and lungs.

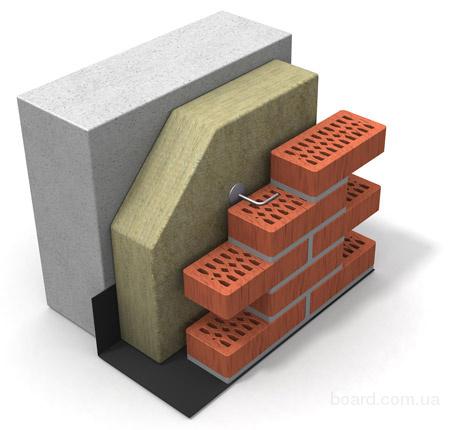

Facade thermal panels with stone-like clinker tiles (outer side) based on polyurethane (inner side) allows for simultaneous cladding and insulation of the facade.  The use of panels with stone-like tiles allows you to avoid the difficulties of joint installation. Installation of thermal panels with stone-look tiles seamless method along the guides ensures the absence of joints in the outer skin.

The use of panels with stone-like tiles allows you to avoid the difficulties of joint installation. Installation of thermal panels with stone-look tiles seamless method along the guides ensures the absence of joints in the outer skin.

The natural ceramic coating of the finish - clinker tiles - is distinguished by its excellent design and special impact resistance.

Tile cladding is not destroyed by fungus, mold, etc., tiles are not subject to abrasion or weathering. Finally, the stone-look tile exterior is simply beautiful and modern.

The variety of design types for cladding thermal panels with tiles (stone, brick) allows you to create facades of a wide variety of decor.

Cladding with facade tiles on a cement-sand base is another opportunity to change the design and appearance of the building, cladding and protecting the walls. The design of the tiles can externally imitate finishing with the most expensive materials - natural stone, marble.

When facing, façade tiles are attached using adhesives. Using lathing when installing façade tiles on wooden walls - necessary condition cladding. The tile then withstands large static and dynamic loads after cladding.  General rule When installing all types of panels, tiles when finishing the wall, they are mounted on the sheathing. The tight fit of the tiles and the entire structure during cladding prevents precipitation from penetrating through the tiles onto the wall, contributing to its preservation.

General rule When installing all types of panels, tiles when finishing the wall, they are mounted on the sheathing. The tight fit of the tiles and the entire structure during cladding prevents precipitation from penetrating through the tiles onto the wall, contributing to its preservation.

A system of profiles, guides, and special fasteners facilitates the installation of tiles, and the use of additional elements of tiling gives a stylish, complete design and an original look to the entire building.

Let us emphasize once again that installing a layer of insulation when installing suspended facade materials provides an additional opportunity to improve the heat-saving characteristics of the building.

The presence of ventilation gaps is especially important for external insulation wooden houses– moisture will not accumulate in the thickness of the log wall, and the insulation will not get wet.

Facade brick

External cladding facades of wooden houses with bricks, layered masonry, leads to a combination of the advantages and design of a structure made of wood and a building made of brick - the main thing is the improvement of heat-saving qualities, in addition, the external cladding of facade bricks reduces the fire hazard.

External cladding with facade bricks has increased moisture resistance and frost resistance. Facade bricks when sheathed will increase the overall strength of the structure. Brick cladding will protect the facade from any type of destruction.  Facade bricks for cladding compare favorably with ordinary brick absence of efflorescence on the material. Many forms of facade bricks for cladding allow you to create a facade of individual design.

Facade bricks for cladding compare favorably with ordinary brick absence of efflorescence on the material. Many forms of facade bricks for cladding allow you to create a facade of individual design.

Facing a house with facade bricks can be done only after complete shrinkage of the log structure. Connecting elements made of galvanized metal (clamps) or flexible plastic connections provide reliable fastening of the façade cladding material to the surface load-bearing walls Houses.  Please note that total weight buildings after facing the facade with brick increases, as does the load on the foundation of the house, the soil, therefore, the foundation should not be too weak.

Please note that total weight buildings after facing the facade with brick increases, as does the load on the foundation of the house, the soil, therefore, the foundation should not be too weak.

Between the brick facade cladding and load-bearing wall a ventilation gap is left at home to ensure natural ventilation, removal of condensate and water vapor from the thermal insulation material. Its size is at least 4-5 cm.

Exterior decoration The use of facing bricks on the facade of a house allows you to qualitatively transform the design of your building, because among building materials brick is a symbol of respectability and strength.

Facing artificial stone of any type of building significantly wins the debate with plaster, which constantly requires attention and care. Brick is a very durable building material that does not require any additional maintenance.

During production, modifying additives are added to the source material - clay - which provide the brick with high strength, reliability, and durability.

Being an excellent insulator, facing brick highly durable, has low water absorption and high frost resistance.

Styrofoam Cladding the facade of a house with foam plastic is effective method insulation of the building. This material has a number of significant advantages:

Cladding the facade of a house with foam plastic is effective method insulation of the building. This material has a number of significant advantages:

- Resistant to frost;

- Does not deteriorate due to changes in humidity;

- Resists exposure to sunlight;

- Various types of foam can be applied to the surface of the foam. facade paint and plaster;

- polystyrene foam is affordable compared to others finishing materials;

- the technology for mounting on walls is quite simple; foam can be used to insulate walls both outside and inside the building;

- energy consumption for space heating in the house will be significantly reduced.

Question how to sheathe a wooden house outside is a purely individual matter.

For example, a house built from rounded logs, as a rule, is not sheathed with anything - it is enough only to impregnate the wood with protective reagents that prevent deterioration in appearance, rot, and insect damage, which also increases the performance qualities of the material.

Another thing is a cottage made of timber, or even more often, a frame-panel house.

External wall cladding insulates the building from weather conditions; You can install such a system on the walls or roof of a building.

Sheathing materials are resistant to moisture, insects, and fire. However, exterior wall cladding requires regular inspection for insect infestation to protect the interior structure of the home.

Some cladding systems are designed specifically for fire protection.  Installation of the cladding system is possible on brick, wood, and cement surfaces.

Installation of the cladding system is possible on brick, wood, and cement surfaces.

As a rule, external wall cladding does not require additional maintenance after installation; The lifespan of the cladding is up to fifty years, depending on the type of material used for the cladding.

Before starting any work, you first need to think through the visual design of the house, decide on the type of materials, calculate volumes, install windows and doors.

In general, when cladding the facade of a wooden house, it is possible to advantageously emphasize in the design precisely the advantages of wood - a traditional building material for Russia.

Wooden elements used in finishing the facade will give a unique appearance to the building, and use in cladding various styles design in their production will allow you to organically combine carved wooden elements with any facade finishing - plastic, brick, decorative plaster.

Looks especially good wood trim platbands, attics, roof overhangs.

The question of how cheaper it is to decorate the facade of a house is relevant for almost all owners of private buildings. After all, on the one hand, you want the cladding of your home to be of high quality and aesthetically attractive, but on the other hand, it is obvious that there is no need for unjustified expenses in pursuit of “exclusive” and stunning appearance. Rare are those families who can afford any solution without regard to its cost.

But it’s definitely not worth going to the extreme, settling on the most budget option, without an objective assessment of the ability of the selected material to “resist” the aggressive outdoor environment - wind, rain, frost, snow, etc. Perhaps you want to verify in practice the effectiveness of the saying “the miser pays twice.”

Of course, it won’t be possible to decorate the façade of a house cheaply, but choose optimal material, which, with all other performance characteristics being equal, will have a lower price, is quite realistic.

Criteria for choosing wisely

In order to decide what is the best way to decorate the façade of a house and not lose financially, it is very important to clearly define the criteria that will help identify the advantages and disadvantages of one or another option.

First of all, you should pay attention to the appearance of the finished facade. Of course, the “presentability” of the cladding is a very, very subjective concept, directly depending on the personal tastes of the owners. However, such parameters of the materials used as:

- number of color variations and textures offered,

- resistance to fading and other visual defects,

- similarity to natural raw materials (if an imitation product is considered)

Under no circumstances should it be ignored. They will help you form an objective impression of the product.

The next quite obvious criterion is the durability of the material. Agree, it will be very sad if an inexpensive house facade turns out to be a real headache with the need for annual reinnovation work. If the type of cladding you like good timing services - know you are on the right track.

It's no secret that façade material is not enough to simply choose. It also needs to be installed. The complexity of the task, the presence of seasonal restrictions, the volume of auxiliary elements and materials - all these factors must be taken into account.

And finally, the final cost of the external cladding. This should include:

- cost of material per kilogram or square meter;

- price of components, tinting, necessary equipment;

- cost of installation (and, if necessary, preparatory work).

All other things being equal, you can safely focus your choice on the final cost of finishing the facade.

Popular options for exterior home decoration

Most often, owners of private houses prefer facade cladding:

- siding;

- facade plaster;

- block house;

- facing bricks - ceramic or clinker;

- facade tiles.

Siding - a good choice or not?

The main types of siding used for cladding the facades of houses are vinyl and basement. Aluminum is used extremely rarely in residential construction. The key advantages of the material are safety, relative ease of installation, and ease of maintenance.

And the most obvious drawback is the artificial appearance. And, we can say that this fact practically negates all the advantages. In Europe, for example, siding is used exclusively when it is necessary to clad outbuildings or temporary buildings. And although basement siding, unlike vinyl, imitates natural brick or stone, it still has a plastic feel to it.

As for the service life, siding manufacturers claim that their “brainchildren” can serve faithfully for 40-50 years. But in practice, this figure is usually much less, since the material is fragile in severe frosts, unstable to deformation, and prone to fading. Cases when siding is sad to look at after only 5 years of use are, unfortunately, not uncommon.

When installing siding in the cold season, it should be taken into account that the material has a high thermal expansion rate.

average cost

Vinyl siding will cost you about 200 rubles/sq.m. m. The total cost of such cladding, taking into account installation and the necessary auxiliary elements, is about 1,500 rubles / sq.m.

Basement siding is a more expensive pleasure. The material itself costs an average of 400-500 rubles/sq.m. The actual cost of finishing a house with it is 3000 rubles/sq.m.

Advantages and disadvantages of plaster

Plaster is a coating that can provide the facade with a decent appearance; moisture-resistant, breathable. Depending on the connecting link, facade plasters are:

- mineral (base - cement);

- acrylic (base - acrylic resins);

- silicate (based on liquid glass);

- silicone (based on silicone resins).

Variety of textures and color range this material is very limited. In the vast majority of cases, such cladding must be additionally painted. And the texture can usually be chosen either rough or rustic.

The service life of a façade finished with plaster is 7-10 years. And although plaster becomes stronger over time, it is not resistant to mechanical damage.

Installation subtleties

It takes 6-8 weeks to decorate a house with an area of 150-200 square meters with facade plaster. The surfaces must be primed first. “Wet” processes make the installation of facade plaster very dependent on weather conditions and the season.

Note! Low vapor permeability acrylic plaster makes it impossible to use it in tandem with insulation such as mineral wool.

Only mineral plaster is “suitable” for aerated foam concrete base.

average cost

- Mineral plaster. The cost of the material is about 40 rubles/kg. Plaster consumption per square meter is 3 kg. Total cost per square meter including installation fees and all necessary materials- 2000-2200 rubles.

- Acrylic plaster. The cost of the material is 50 rubles/kg. Consumption - 1.5 kg/sq.m. Total cost - 2500.

- Silicate plaster. The cost of the material is 100 rubles/kg. Consumption - 2.5 kg/sq.m. Total cost - 2800.

- Silicone plaster. The cost of the material is 100 rubles/kg. Consumption - 3 kg/sq.m. Total cost - 3000.

Features of a block house

Block house is a subtype of lining whose front surface imitates a rounded log. This material is natural and environmentally friendly, but quite expensive and short-lived. Not fire resistant. Defects in appearance include knots, cracks, wormholes and other defects characteristic of wood.

When purchasing a block house, you should make sure that it is not “raw” - otherwise there is a high risk that the material will rot.

Important! A block house, like any wooden surface located in the open air, needs periodic updating - coating with special protective compounds, etc.

average cost

The price of a block house largely depends on the type of wood. The cost per square meter can range from 400 to 1000 rubles (including installation work and necessary processing - 3000-4000 thousand)

Facing brick - quality and durability

Facing ceramic brick is an environmentally friendly material made from natural raw materials (clay), manufactured using special technology. It is frost-resistant, durable, exhibits low moisture absorption and good sound insulation. Face clinker brick is produced in the same way as ceramic brick, but is fired at a higher temperature, so that no voids remain in it. Compared to ceramic, it has even better physical characteristics.

Facing bricks have a wide range of textures, shapes and colors. With it, your facade does not risk fading. The only possible external drawback is the appearance of efflorescence.

House finished face brick, will look luxurious for decades. Clinker brick is an example of durability; it can withstand more than 150 freeze-thaw cycles.

The cladding of a building with bricks should be taken into account at the design stage (the material is laid on the main foundation). Otherwise, additional strengthening of the foundation will be required.

average cost

The range of prices for the material is quite wide, but, naturally, having the status of a leader in durability and quality, facing brick simply cannot be cheap. Professional brick laying is also quite expensive. Therefore, the average Russian rarely chooses this option for façade finishing.

A square meter of ceramic brick will cost 1200-3000 rubles, clinker brick - 3600-4000. A square meter of a finished, beautiful and insulated brick facade will generally require up to 6,000 rubles.

Facade tiles: pros and cons

Facade tiles are a modern and reliable building material. Not afraid of moisture, strong, durable. With high-quality installation, it ensures an excellent appearance of the house. The service life of a façade finished with ceramic tiles can be tens of years. True, a lot depends on the quality of the adhesive solution.

Installation of facade tiles is usually not easy. The process becomes more difficult:

- the need for careful preliminary surface preparation;

- the difficulty of achieving straightness of the seam;

- high fragility of the material before installation.

average cost

Facade tiles, in comparison with bricks, demonstrate no worse quality and aesthetics of the final result, and are much cheaper. The price per square meter of material is 1000-1500 rubles, but the actual cost per square meter of such cladding usually does not exceed 3000.

Finishing the facade of a house can only be truly inexpensive if you do it yourself. As you can see, some materials, at first glance, seem extremely cheap, but in practice, taking into account the cost of all the auxiliary elements and the entire scope of work, it turns out that this is not the case. And only if you decide to take on this rather difficult work yourself can you talk about significant savings.

This video will introduce you to the rules for installing vinyl siding:

When choosing materials for facade cladding, it is very important to objectively assess their “prospects” - how long they will last, how often they will need maintenance and renewal, what investments and how soon they may require.

It would be a good idea to look at the photos on the Internet. various types facades, feel which “execution style” you prefer. Appearance You have to not only like the house, you have to be in love with it. It has been proven that this moment directly affects the psychological comfort of staying inside or near housing.

Photos of various cladding options are unlikely to help you understand how cheaper it is to decorate the facade of a house, but they will clearly help you get a clear idea of what awaits you in the end when using this or that material.

Having thoughtfully weighed all the nuances, we are confident that you will be able to make the right decision that will be optimal for your family, both from a financial and aesthetic point of view.

Siding is a facade covering of the walls of a building, consisting of panels laid on a sheathing.

The range of panels is varied: they can be made of various materials and have a variety of shapes, textures and colors.

Installation of siding is quite simple, its operational period can reach fifty years.

In this article you will learn how you can cover the outside of a house other than siding.

The popularity of siding cladding is primarily associated with its characteristics, which are inherent this species material. Houses covered with siding have an aesthetically attractive and very neat appearance.

Distinctive characteristics of siding are:

- Durability of the material;

- a large assortment;

- variety of materials (wood, vinyl, metal);

- ease of care;

- the presence of an air gap between the wall of the house and the cladding prevents the formation of mold or mildew;

- quite easy to install;

- UV resistant;

- frost-resistant;

- waterproof;

- has resistance to mechanical damage.

Vinyl siding is quite fragile at sub-zero temperatures, flammable and quite flammable..

Metal siding requires care during installation, since even with a slight bend the material cannot be restored: the panel must be replaced.

Wood siding is not durable.

Despite the presence of shortcomings, siding still has much more advantages, which determines the rapidly growing interest in this type of cladding.

Siding analogues

In addition to siding panels, you can also clad your house with other materials that are no less common on the construction market.

These include:

- decorative plaster;

- porcelain stoneware;

- sandwich panels;

- natural and artificial stone;

- tree;

- brick.

Each house cladding option has its own advantages and disadvantages. Before choosing a cladding option, you should be guided not only by the aesthetic appeal of the material, but also by its technical characteristics.

Decorative plaster

Decorative plaster is a budget material, so it is widely used.

Plaster can be non-aqueous or water-free. Popular is mineral plaster, which is made on the basis of cement and additional components.

Decorative plaster can be polymer, silicone or silicate.

ATTENTION!

The material is presented in the form of a dry mixture, and for application this mixture must be diluted with water. Various colors and admixtures can be added to the plaster mixture to achieve the desired color and effect.

Advantages decorative plaster are:

- no toxic fumes;

- high adhesive ability;

- long shelf life of the dry mixture;

- no special care required;

- ease of manufacture and application;

- does not absorb dirt;

- big variety color solutions, textures;

- the vapor permeability of the material ensures a comfortable microclimate in the room;

- resistance to temperature fluctuations;

- good sound insulation and heat insulation properties.

The plaster perfectly withstands atmospheric and mechanical influences.

Decorative plaster has disadvantages, but they are not decisive when choosing cladding:

- in the absence of a reinforcing mesh, the plaster is susceptible to chips and cracks;

- repair work must be carried out at temperatures above +5° C;

- the cost of decorative plaster is much higher than usual.

When using decorative plaster, you should follow the recommendations for its application.

When creating a textured relief, professionalism and a lot of time are required.

Decorative plaster

Porcelain tiles

Porcelain tile is a compressed and fired clay mixture with the addition of quartz, feldspar and natural-based dyes.

The main quality of the material is strength.

Porcelain tiles are made in the form of slabs of various thicknesses, textures and colors. It has properties that are not inferior to natural stone.

The main indicator of the color, structure and texture of a material is its composition, which includes manganese, chromium, iron, zirconium or cobalt salt. The surface can be matte, polished, embossed, polished or glazed.

The features of porcelain stoneware are:

- high strength;

- durability;

- independence from weather changes;

- environmental friendliness;

- no fading;

- soundproofing;

- thermal insulation;

- fire safety and protection of walls from fire;

- resistance to microorganisms;

- ease of installation;

- a ventilated façade ensures a comfortable microclimate.

The aesthetic appearance of a porcelain stoneware building is ensured by the textured coloring of the material., it is easy to maintain and simple to repair.

The disadvantages of porcelain stoneware are the heavy weight of the slabs, which requires a solid foundation for the building and load-bearing walls and high cost.

Porcelain tiles

Sandwich panels

Sandwich panels are a thin aluminum sheet with a thermal insulation layer. They are used for finishing office, administrative, sports and socially significant facilities.

The panels are available in glossy, matte, lacquered color coatings, and also treated with powder or polymer mixtures.

The advantages of sandwich panels are:

- environmental friendliness;

- soundproofing;

- good thermal protection;

- a light weight;

- resistance to corrosion and rotting;

- ease of installation;

- durability;

- low cost.

Sandwich panels are easy to install and the structure itself is not heavy, which does not require additional reinforcement of the walls.

- the possibility of having fire hazardous insulation in the panels;

- limited assortment;

- During installation, the joint areas must be covered with a special sealing tape.

CAREFULLY!

The installation of sandwich panels should be entrusted to professionals, since minor errors can reduce the thermal insulation qualities of the cladding.

Particular attention should be paid to the places where the slabs are connected.

Sandwich panels

Natural and artificial stone

Facade stone can be natural, which is classified by species, and artificial, which is an imitation of natural rock or organic mineral.

Natural stone

There are several types of stone cladding for masonry:

- “from the die”;

- "Castle";

- "Plateau";

- "Shahriar";

- "Assol";

- "Rondo".

The texture of natural stone can be granite, marble, limestone, slate, sand.

The advantage of natural stone cladding is durability and strength. The material is environmentally friendly, frost-resistant and fireproof.

Natural stone cladding requires its treatment with protective agents to prevent the formation of salts on its surface.

The disadvantage of natural stone cladding is its cost and heaviness.

Natural stone

Fake diamond

It is produced by mixing polymer and mineral components, which are poured into molds and hardened under a brick press.

Happens:

- clinker;

- concrete;

- architectural;

- polymer sand;

- resin based;

- ceramic.

Artificial stone has similar characteristics to natural material, but is much lighter.

Compared to natural stone, the resistance of artificial stone to external influences significantly less, and therefore the service life is reduced.

Fake diamond

Cassette facade

Cassette facades are cladding material in the form of slabs. Cassettes can be composite or metal. The design of the structure is worked out by computer, based on the shape, size of the building and the material of the cassettes.

Small cassettes are made from aluminum. For large forms, composite materials are used.

Cassettes differ in color, size and texture.

Positive characteristics of a cassette facade:

- strength;

- resistance to atmospheric and mechanical influences;

- resistant to corrosion;

- ease of construction;

A high degree of decorativeness provides individuality to any building equipped with cassettes.

A significant disadvantage of this type of façade improvement is its high cost.

Cassette facade

Tree

Wood is used as cladding to give the house a natural look.

Can be used under wood modern views cladding:

- lining;

- block house;

- facade board (planken);

- imitation timber.

The lining is a solid board. It has different class quality. It is lightweight, accessible and low cost.

Block house is a high-strength material that is a covering in the form of timber. Classified by color and texture.

Facade board is a profile material resembling siding panels. The peculiarity of the installation is the technology of the permissible distance between the boards to ensure ventilation.

Imitation timber looks like a board. Mounted using tongue-and-groove technology.

The advantages of wood are environmental friendliness, non-toxicity and good thermal insulation and sound insulation properties.

A significant disadvantage of wood is its susceptibility to rotting and fragility. However, with regular treatment of a wooden facade, its service life increases significantly.

Brick

The brickwork that is used to clad the building is designed to give the building strength and protect the internal load-bearing wall.

The structure of facing brick can be:

- ceramic;

- clinker;

- silicate;

- hyper-hyped.

Based on the front surface, bricks are classified into:

- smooth;

- raised;

- glazed;

- engobed.

Brickwork can be of different colors, and the material itself differs not only in texture and composition, but also in color.

The main advantages of brick cladding are strength, resistance to external influences, and protection of the house.

In addition, the brick has:

- fire resistance;

- environmental friendliness;

- frost resistance and low thermal conductivity.

The disadvantage of brick cladding is its significant weight. In addition, the price of bricks is quite high.

Conclusion

Thus, quite a lot of alternative cladding options, in addition to siding panels, can be used when finishing the facade. You can determine what exactly is suitable in a particular case, based on the price, characteristics of the material, the ability to install it yourself, as well as in accordance with design ideas.

Useful video

In this video we will look at all analogues of siding:

In contact with

A wooden house is the highest priority for many individual developers: it is environmentally friendly, it creates the most favorable atmosphere for human health, it heats up quickly and retains heat well. But wooden walls often require cladding for protection from adverse influences, insulation and decoration. Let's consider the options for choosing materials for cladding the outside of a wooden house and for creating an exclusive exterior.

Requirements for facing materials for house cladding

When choosing a material for facade cladding, you need to remember the basic requirements that it must satisfy:

Materials for cladding a wooden house

Facade brick

A wooden house lined with facade/cladding bricks () looks very beautiful, modern, solid and reliable. It retains heat better, it is not afraid of changes in humidity and temperature, but at the same time, covering a house with brick is a rather complicated and expensive task. To build new ones around the perimeter of the house brick walls, it is necessary to strengthen the foundation, and in fact, build a new one, linking it with the old one. In addition, you will have to solve the problems of joining the new walls with the roof.

Siding

- a modern, beautiful and inexpensive option for cladding a wooden house. This construction material accessible, durable, fireproof. It is easy and quick to install.

Siding can be vinyl or metal. Vinyl is lightweight, durable and reliable material, it is not afraid of either heat or frost, is easy to clean and looks great. The richness of the color range makes it easy to choose the desired shade of color. Metal siding is a little more expensive, heavier and looks a little cold, but is just as reliable and durable.

Lining

Wood as cladding allows you to preserve the originality of a wooden house, its environmental friendliness and beauty. This material absorbs sounds well and retains heat. Cladding boards for house cladding are very strong and durable. For biological protection and fire safety, wood is impregnated with special compounds.

Imitation of timber

This type of cladding is a board made of pine or spruce, which is laid horizontally, with no visible intermediate grooves. A smooth and beautiful cladding surface is achieved, which can go well with stone or metal.

Block house

A peculiar type of lining, which is not made in a flat form, but in the form of convex panels. The cladding looks like a rounded log, giving the building the classic look of an old wooden house. The block house is made mainly from coniferous wood: pine, spruce, etc.

There are other options for cladding a wooden house, for example, thermal panels with clinker tiles, facing tiles, and heat-insulating plaster. But these types of cladding are much less popular in our country.