Brick wall cladding technology. How to clad a house from foam blocks

Modern technologies allow you to perform work independently without special skills. All you need is all necessary tools and materials, as well as elementary subtleties and requirements for the installation process. In our article, we will learn all the nuances of building buildings from blocks and bricks.

Foundation selection

Building a house must begin with the selection and construction of a foundation. We will not consider all types of grounds, their advantages, but consider the most optimal option. For this type of construction, a tape structure is best suited. Of course, you can choose other foundations - it depends on your construction and financial capabilities. The most reliable base is considered to be a monolith, but it will cost more.

Preparatory stage

At the preliminary stage of the process, a number of sequential actions should be performed:

- First of all, you need to analyze the soil on the site, which will allow us to find out the information we need. Namely, such indicators: the depth of soil freezing and the occurrence of surface waters, the degree of density of the earth.

Attention! If the soil on the construction site is weak, sand and gravel reinforcement should be added.

- Next, we proceed to digging a trench, which is carried out according to design data;

- Fill up the sand and tamp it well. The thickness of this layer should not exceed 30 cm.

- After filling the sand, you need to put a film on the surface, which will retain the moisture of the solution.

Attention! Houses made of foam blocks require laying a wide foundation. It is worth considering that the thickness of the wall should be thinner than the base.

We fill the solution

Concrete pouring must be performed in the following sequence:

- After completing the trench, you need to install the timber formwork. It is worth considering. That it is imperative to consider the level of the plane.

- Next, we put the reinforcement frame made of metal rods into the ditch.

- The rods can have different sizes from 8 to 12 mm.

- We mix the cement mortar. The standard way to prepare it can be found on the label of the cement bag.

- You need to carry out the work in stages, namely in layers of 30 cm. You can use a special vibro device. To get rid of irregularities and excess air.

- When we fill the last layer, cover the concrete with a film that will provide protection against sun rays and possible sites.

Attention! The main note of the whole process is the need for constant water addition when drying the cement.

A house made of blocks and bricks is a more reliable and high-quality structure than a monolith tape. But, in order to achieve such a result, it is necessary to meet many requirements and factors. A building of this type requires the installation of ventilation, therefore, it is necessary to provide for the presence of holes for pipes.

Creating an inner wall from a foam block

The construction of houses from blocks and bricks is gaining momentum in popularity. Today, such buildings are found more and more often. Aerated concrete technology was invented in Europe, where they strive to save money. It is worth highlighting the following advantages of the material:

- Structures made of foam blocks and bricks have a high level of sound insulation;

- Simplicity and availability of construction work;

- Lightness of elements that do not create a strong load on the base of the house;

- Possibility of optimal interaction with other materials;

- Keeps warm well.

Attention! There is one drawback - the level of strength is lower than that of a brick, and therefore facing is performed.

We carry out laying of material

The masonry process is performed in the following sequence:

- We clean the surface of the base of the house from various contaminants;

- Preparing a solution for blocks;

- With a spatula, apply the mixture evenly to the surface of the building object;

- We lay the block, tapping on it with a hammer, so that it sits tightly on the solution;

- Before laying the second block, you need to lubricate the end of the fixed element with concrete;

Attention! The minimum overlap should be 10 cm.

Features of the masonry process

A house made of bricks and foam blocks should be started with the study of theoretical points. To get the job done, you should familiarize yourself with the situations that may arise when laying materials:

- Reinforcement must be performed every 4 rows. For this, glass wool nets can be used.

- It is also necessary to lay the reinforcement rods. With a special device we make holes for metal pins that connect two walls to each other. After that, the seams must be filled with mortar.

- It is very important not to disturb the verticality of the foam block. The simplest solution to this problem is the constant monitoring of the elements by the level.

- To make the walls of the interior, you need to choose blocks with a thickness of 10 cm.

External wall made of bricks

Necessarily built with brick cladding. Initially, before performing work, you should choose optimal material... For such a process, you can choose blocks from ceramics, solid and hollow types of bricks.

Attention! The best material for cladding is silicate brick M 150. It is most suitable for the construction of the facade, as it has an attractive appearance, and is resistant to the negative effects of atmospheric precipitation. Plus, there are a huge number of shades.

After we have decided on the material, we can begin to perform the masonry. To do this, you must consistently perform the following actions:

- First you need to knead a high-quality solution. It should be plastic, without lumps, and have sufficient density.

- Use a notched trowel to apply the mixture;

- As with work with blocks, it is necessary to carefully coat the ends;

- In the places of contact between the brick and the pin, which is arranged in foam, you need to use a little more concrete mortar, which will increase the degree of contraction of the materials.

Attention! The horizontal seam thickness should be less than 1 cm.

So we built walls of bricks and blocks that will keep heat as much as possible, which will enhance the protective capacity of the building frame. Now let's find out if such a structure needs to be heat insulated? We'll talk about this in the next section.

Thermal insulation for building from foam block and brick

For regions that are characterized by very cold frosty winters, freezing of the premises will occur if the house is built without additional insulation. Construction specialists strongly recommend the use of modern means that will help move the condensate of precipitation closer to the facade of the building. There are some recommendations regarding thermal insulation:

- For this type of building, it is better to use expanded clay, which is sold in powder form. Such a tool is practical, since it provides for the possibility of processing over the entire surface of the wall. Plus, the substance is not capable of disintegrating or deforming when exposed to moisture.

Attention! It should be noted that this material has a higher cost than foam. Plus, air passes between the granules.

- You can use roll or plate elements for insulation. If they are used in conjunction with film, then a better result can be achieved. But, there is also a minus - this is the sequence of construction work.

When making brickwork, you can simultaneously join the joint. This can be done in the following way:

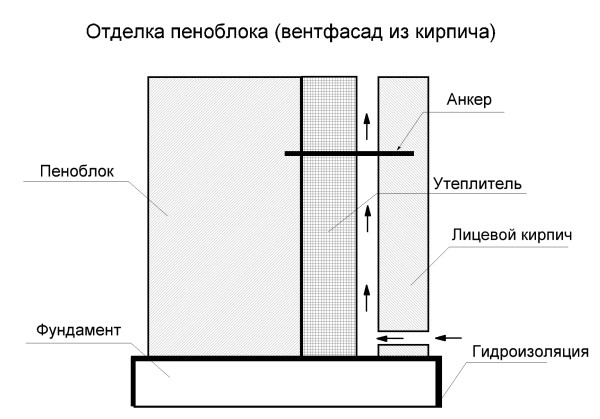

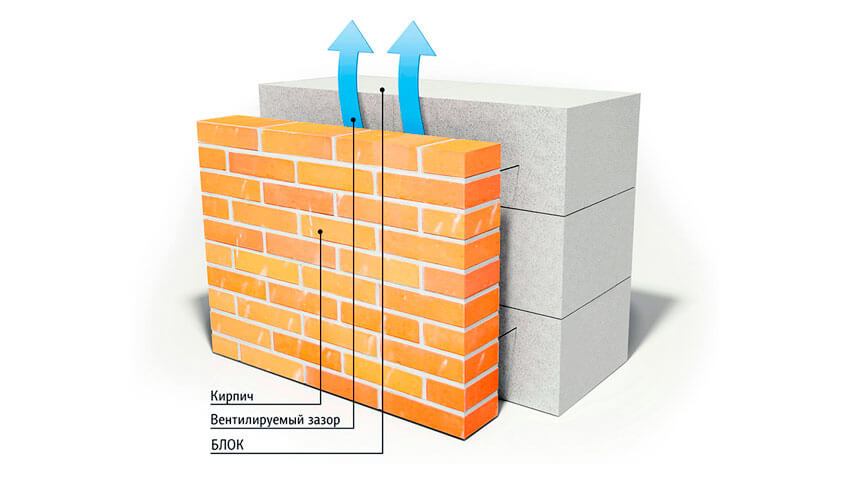

- We leave an empty space between the block and the brick wall, which will allow us to create a certain ventilation system. This action will perform ventilation functions, but insulation will be needed, for example, heating from the inside.

In conclusion, I would like to say that the construction of a building made of foam and brick cladding will create a durable and strong structure of the house. In our article, we examined all the pros and cons of this construction project, now it's up to you to decide.

To build new house you do not need to be a professional builder, the main thing is to know the basic subtleties of the workflow. We invite you to familiarize yourself with these subtleties, learn a few rules regarding installation works, and find the time and money to make your dream come true - to build a country house.

Let's start the article with the most important thing - the foundation.

Strip foundation

We will not make comparisons, describe the advantages of various foundation options, but simply say what is considered the most optimal and practical belt structure... If you want or find something else where the price is most acceptable to you, that's good.

But we will describe our example of building a house from bricks and foam blocks on a strip foundation.

Preparatory work

- The first step is to analyze the soil at the site in order to obtain several indicators. The first is the depth of soil freezing, the second is the presence of groundwater, the third is, in fact, the density of the soil itself.

For your information! If the soil is weak, then it can be strengthened by creating a cushion of sand and gravel.

- Dig a trench according to the data received.

- Pour sand into it and tamp it well. The thickness of the pillow should be no more than 30 cm.

- Place a plastic wrap on the sand surface to prevent the mortar from drying out.

Note! The house is made of foam blocks and requires a wide base, in no case should the thickness of the wall be allowed to be greater than the thickness of the foundation.

Pouring the foundation

- After the trench is prepared, it is necessary to erect a wooden formwork, observing the level of the planes.

- Lay an armo-frame made of metal rods or fiberglass gratings into the trench.

- Prepare a mortar from cement, sand and water, adding no more than 1% of the total volume of the plasticizer. The preparation instructions are usually indicated on the package with the cement.

Important! Filling work should not be carried out during rain or snow. If, nevertheless, this happened, then the fresh cement must be covered with a waterproofing film.

- It is necessary to pour the solution gradually, through each layer. 30-40 cm using a vibrating tool to remove air bubbles.

- After finishing the pouring, cover the freshly poured foundation with a black opaque film, which will protect the material from ultraviolet rays.

Note! Another feature, during the entire drying of the solution, every day it is necessary to water it with water.

Someone will say that building bricks () are better and more reliable than monolithic tape, but this all depends on various factors. For some, for example, buying a brick is expensive, as well as hiring workers to lay it, but someone simply does not like DIY work.

When building a house from foam blocks and bricks, do not forget to leave ventilation holes in the foundation frame so that the base of the house can "breathe"

Foam block - inner wall

Projects of houses from foam blocks and bricks steel in recent times very popular, people felt the advantage of well masonry, both from a technical and financial point of view. The technology came to us from Europe, where people have long learned to save money.

What is good about the foam block

- An excellent indicator of sound insulation.

- Simple and affordable installation.

- Lightweight material that does not put a heavy load on the foundation.

- Interacts with various finishing materials.

- The foam block also shows itself well in terms of keeping warm in the room.

Although there is an unpleasant side, the strength of this material is inferior to brick, which is why facing the foam blocks with bricks is required.

Laying material

- Clean the surface of the foundation / floor, in general, what will be the masonry, from dust and dirt.

- Prepare the mortar for the foam block, its consistency is slightly different from the composition of the cement mortar for the foundation.

- Apply the mixture with a spatula to the work surface.

- Lay down the block by tapping lightly on it with a mallet.

- Before placing the next block, coat the vertical end of the already fixed mortar material.

- Overlap the masonry so that the seams do not overlap.

Masonry features

Before laying a brick on a foam block house, check out some of the points that may raise doubts during the laying of foam concrete blocks:

- Each row 4-5 and window openings should preferably be reinforced using fiberglass mesh.

- It is also necessary to use reinforcing bars. For this, holes are made with a special chasing cutter. Metal pins are inserted into them, connecting two walls (external - brick and internal - foam concrete), after which the grooves are filled with mortar.

- It is equally important for the foam block to maintain a vertical plane. The easiest way to follow the level is to pull a string between the two corners and lay on it.

For your information! Do not think that projects of houses made of bricks and foam blocks are distinguished by wide walls, on the contrary, they may be narrower than with wooden frame with double-sided thermal insulation.

Brick - outside wall

So we have come to the moment when the brick is facing the foam block. Before starting work, it should be noted that you can use both ceramic blocks and. A striking example of a silicate material is double silicate brick M 150.

It is ideal for the façade side, looks attractive and weather-resistant.

Brickwork

Not many people know how to properly lay a house made of foam concrete with bricks, but now we will try to help you in this process.

- First of all, prepare a high-quality solution, it should turn out to be a homogeneous mass, without lumps and not too liquid.

- It should be applied with a notched trowel.

- As in the case of foam blocks, it is necessary to coat all ends.

- In those places where the brick is in contact with a metal pin embedded in the foam concrete, it is necessary to apply a little more mortar. This is required for one hundred percent adhesion.

Here you have a wall of brick and foam block that can keep the heat in the room, providing reliable protection for the entire frame of the house. One question remains - is it appropriate to use thermal insulation material here?

Insulation between foam block and brick

As practice shows, in most regions the winter is quite harsh, the walls are very cold if they are built without insulation. That is why experts advise using modern materials to move the dew point closer to the front.

- Expanded clay is best suited for such cases - bulk material... Firstly, it is practical, you can safely erect walls to the very top, and then fill it in the space between them. Secondly, it does not decompose or deform when exposed to moisture.

Note! On the other hand, the cost of expanded clay may unpleasantly surprise you, it is still more expensive than polystyrene. In addition, air passes freely between the granules.

- As for other roll or plate heaters, their use in conjunction with a windproof film ensures the greatest efficiency of their properties. The disadvantage is the construction of walls, since it is necessary to erect one by one, then the internal, then the external wall, 1-1.5 m in height.

- You can leave a space between brick wall and the foam block is empty, so to speak, to make a ventilated channel. It will be very similar to a ventilated facade system. Only thermal insulation is still required, for example, from the inside of the house, using some kind of liquid material.

Finally, I would like to say that all projects of houses made of foam concrete blocks lined with bricks are durable and reliable in comparison with conventional buildings made of foam concrete products. That is why it is worth considering, maybe there is a sense of a small overpayment at the initial stage of construction, but at the same time saving on repair work in the future?

Output

Now you know how houses are built from foam blocks and bricks, and you can, if you wish, do all the work yourself. There is only one moment that can stop you - time.

Indeed, the entire editing cycle will take more than one week, especially if you work alone or with a partner. If you have free time, then feel free to dare, after all, this is a tangible saving on labor.

A foam block house meets all modern standards for environmental friendliness, fire safety, sound insulation, thermal conductivity. In addition, the construction of a house made of foam concrete according to the project is carried out much faster and is cheaper than from brick. The best option is to build a house from foam blocks and cover it with bricks.

Photo

Instructions

Projects of houses and cottages made of foam concrete

A distinctive feature of stone house projects in our catalog is their variety, most of them are capital houses of average area - from 100 to 200 sq.m., cottage projects from 200 to 300 sq.m. are also presented, a slightly smaller number are estate projects from 300 sq.m.

If we consider this category of projects from the point of view of material for external walls, then this is the most popular and thorough choice of a prudent owner, both in terms of price and reliability. In terms of environmental friendliness, modern building materials are practically not inferior to natural materials, and as a rule, they surpass them in terms of service life.

Despite the fact that the overwhelming majority of projects are standard (ready-made) projects, it is still quite simple to add unique features to them, for this you need to purchase a project and contact us for this service. This approach significantly reduces material costs for a project, which is essentially unique or individual.

With your own hands

Wall masonry made of foam concrete blocks

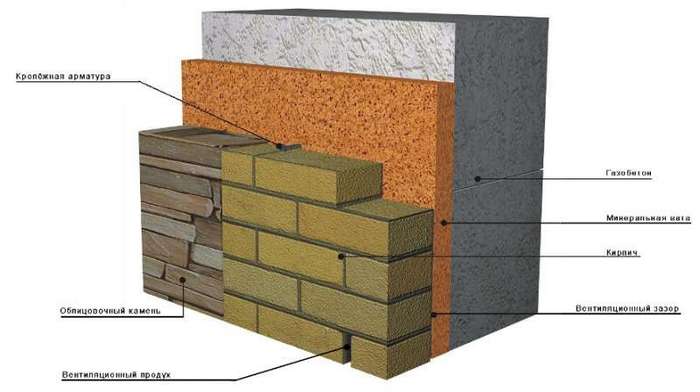

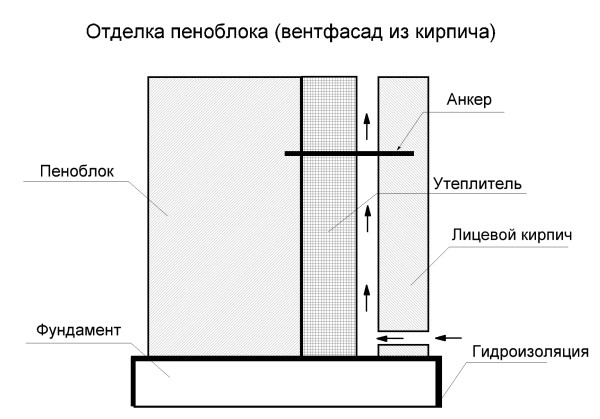

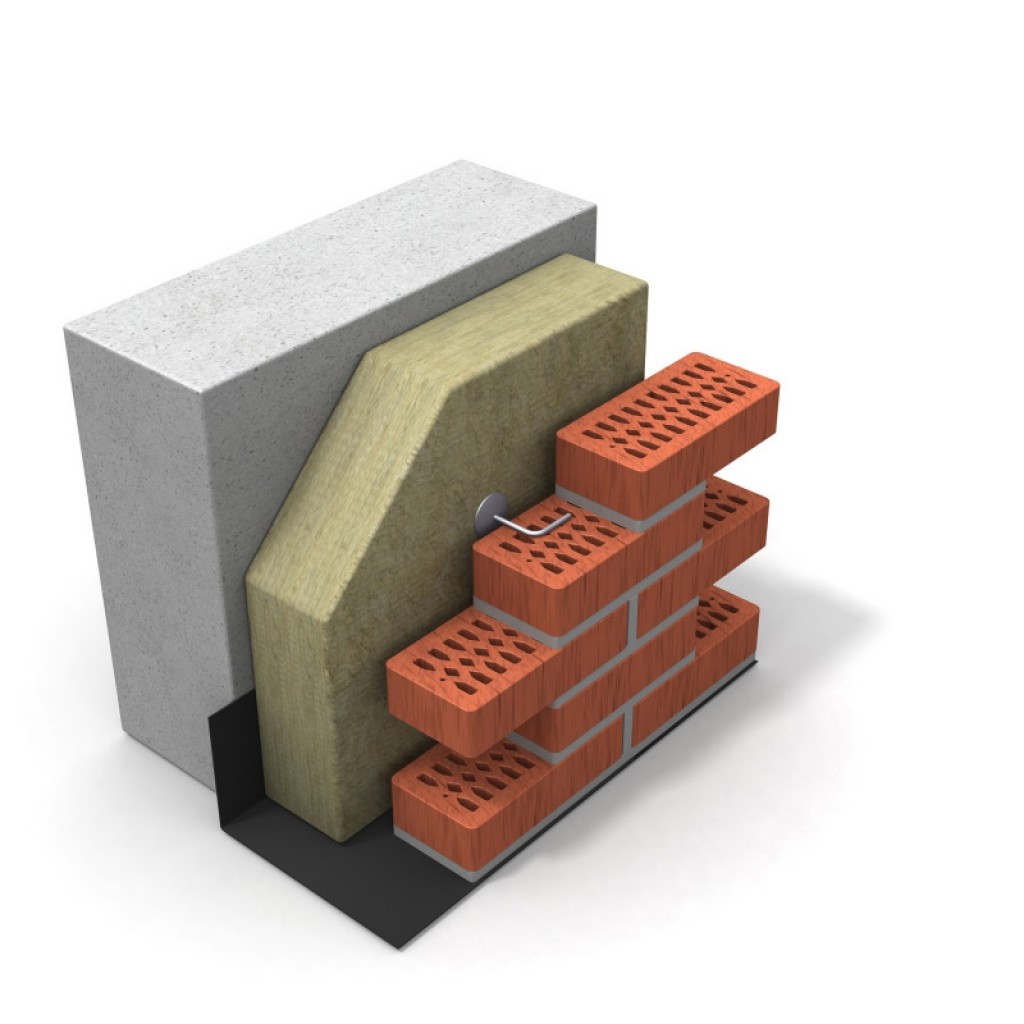

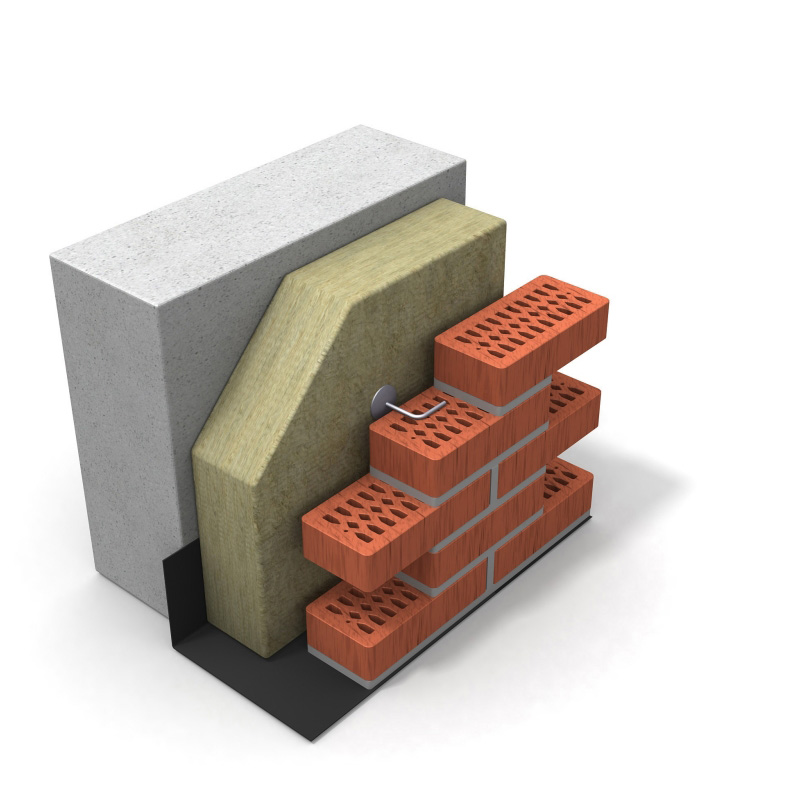

First of all, it must be borne in mind that the masonry of the walls, made of two types stone material, is called mixed, or combined. Walls erected according to the combined method have an external and an internal part. The outer part of the wall is lined, as a rule, facing brick or any other facade protective and decorative material, product or facade system. The inner part of the combined wall consists of heat-efficient building materials, such as aerated concrete, gas silicate, aerated concrete or expanded clay concrete blocks. Since between the inner and outer part walls place an additional layer of heat-insulating material, the structures of such walls are called three-layer.

Laying the walls of a house made of foam concrete, aerated concrete blocks is similar to the construction of a wall made of bricks. Rows of walls made of lightweight concrete blocks are tied up as well as brick walls... When laying walls made of foam or aerated concrete blocks, only one type of dressing is used - spoon, when each upper block overlaps the lower one by half the length. Aerated concrete blocks can be easily cut by hand using a hacksaw or an electric band saw.

how to cut aerated concrete blocks manually

It must be remembered that the laying of walls made of foam or aerated concrete blocks must be carried out on a plinth made of moisture-resistant materials for waterproofing from roofing material with an overlap of panels of at least 100 mm or hydrosol, hydroglass, bikroelast, etc. The height of the base of the outer walls must be at least 400 mm from the blind area.

The walls are laid from the corners of the house, making an indent from the facing rows by the amount of the air gap necessary to fill with an effective insulation. It is also necessary to take into account one very important point when building a house from foam or aerated concrete blocks. Masonry walls made of high-quality lightweight concrete blocks should be glued, which significantly reduces the consumption of bonding material, since the seam thickness is only 2-3 mm. Such masonry looks aesthetically pleasing, does not require labor-intensive, and therefore expensive finishing works, and in addition, increases the thermal resistance of the enclosing structures. Unfortunately, in practice, "cheap" low-quality foam concrete produced in violation of technical regulations and production technology, the dimensions of which have significant deviations from the standard indicators, and the blocks are laid on the mortar, which negates all the thermal engineering advantages of this material. If the blocks are laid on mortar, we recommend using a cement-lime mortar of grade 25 or higher (composition by volume: cement M400-500, lime, sand - 1: 0.9: 8).

The minimum width of the walls in load-bearing walls is determined by calculation, but not less than 1030 mm. As a rule, factories manufacturers of aerated concrete blocks offer in their assortment U-shaped tray blocks for the installation of lintels in window or doorways, but most manufacturers of foam concrete blocks do not produce such blocks. In this case, you can apply reinforced concrete lintels, with entry to the walls of blocks of at least 250 mm. Under the support of the lintels, it is necessary to lay reinforcing meshes with cells of 70x70 mm from rods with a diameter of 4 mm.

Where does the interior decoration of a foam block house begin?

Interior decoration of a foam block house Interior decoration of a foam block house begins with an understanding of the material. No matter what technology the construction would use, it is important to remember about the great vulnerability of this material. The worst thing for a foam block is the impact of the environment on it. Constant freezing and thawing of the water inside, leads to many undesirable consequences. Therefore, the external and internal decoration of houses from foam blocks is very important. Without finishing, it is very likely that the blocks will crack, defects are formed due to a violation of the macrostructure.

Given the porosity of the structure of the foam block, I categorically do not recommend using it at high humidity.

So, before proceeding with the finishing, it is necessary to make waterproofing. But, as a rule, treatment with only waterproofing compounds has low efficiency, due to the large number of surface defects. The most the best option exterior decoration of a foam block house is considered to be the construction of ventilated hinged facades.

Interior decoration of the house from foam blocks. Where to begin.

It is advisable to carry out the interior decoration of the walls of the house from a foam block from gypsum plasterboard hinged structures. This is necessary for better surface ventilation. The problem of vapor barrier can be solved by using vapor-tight membranes, which in turn are integrated into the space between the drywall and the wall. In order for the air to move freely in the interior decoration, drywall should be placed at a distance of at least 45 mm from the wall. Do not forget that the porous structure of foam blocks requires the use of special fasteners. This significantly complicates the entire installation process, because for most standard walls (made of brick, wood and concrete), dowels, nails, screws, etc. are used.

Depending on the specific situation, I also recommend making the interior decoration of the house from wood, MDF, chipboard, moisture-permeable wallpaper and acrylic paints on plaster. Just do not forget that such finishing methods depend on the properties of the foam blocks and the ambient air humidity inside the room. If you have a dry microclimate, you can finish it from almost any finishing material.

Equipment

Projects of houses from foam blocks.

The foam block is a modern and economical building material. A house made of foam blocks has a number of indisputable advantages, among which one can single out the lightness of the load-bearing walls, thanks to which you can save money by abandoning a powerful foundation, durability, good heat-preserving properties and foam blocks do not burn.

Another plus is that the foam concrete "breathes", so a person feels good in the house, which is very important to agree.

Foam concrete is an economical material and in the sense of time, finished projects houses from foam blocks allow you to complete construction in the shortest possible time.

It should be remembered that foam concrete and brick are interchangeable and you can build any project of a house from foam blocks from bricks and vice versa.

Foam concrete is made by mixing in certain proportions special foam and filler under pressure. Foam concrete is poured into various forms- this is how the foam block turns out. The service life of foam blocks is not limited, and the most amazing thing is that over the years they only become stronger.

Ready-made projects of houses made of foam concrete are an excellent choice, this is a house that will serve a long and loyal service to its owner.

And what is the difference between finished projects of aerated concrete houses from foam block analogues? The words are similar, but different. Firstly, aerated concrete is even lighter than aerated concrete, at the same time the heat-retaining properties of aerated concrete are worse and it absorbs moisture.

Aerated concrete blocks have high geometric shape accuracy, which additionally facilitates construction.

Firms

Construction of houses from foam blocks

Building houses from foam blocks is a profitable investment for their owners. Indeed, in comparison with the same brick, foam blocks are cheaper, and the thickness of the walls of such a house is 30 cm or more. In terms of thermal insulation properties, corresponding to a meter-long brick wall, this material gives a lot of room for the architect's imagination - foam blocks are easy to saw and combine in various combinations. From aerated concrete, which forms the basis of foam blocks, a lot of various products are made for the construction of cottages - floor slabs, flights of stairs, blocks, jumpers and more. Another advantage of foam block houses is their ability to "breathe", so living in such a cottage is much more comfortable.

Advantages of the foam block

The construction of houses from foam blocks simplifies the supply of communications, in a foam block it is easier to groove channels for electrical wiring, heating systems and left communications. The speed and low cost of installing this material also speaks for the construction. country house from foam blocks, because foam blocks are usually produced in large sizes, which can significantly speed up the process. The foam block, unlike brick, does not lose its mechanical strength in case of fire. And it meets all the sanitary and hygienic requirements for building a house.

Specifications

Ventilation device for walls made of foam concrete, aerated concrete blocks lined with brick

The insulation is fixed on the finished load-bearing wall made of lightweight concrete blocks with wire anchors pre-installed in the masonry (I play the role of clamps: special washers with an anti-corrosion coating), or special disc dowels, at least 5 pcs. for 1 sq.m. To protect the fibrous insulation from blowing, they are covered from the side of the air gap with a wind-proof canvas or other appropriate material (for example, membrane type). It should be borne in mind that an additional 20-40 mm wide ventilation gap must be left between the insulation and the facing layer.

The outer wall, which protects the insulation from adverse external influences and forms the facade of the building, is constructed of facing brick(or lightweight concrete blocks with a plaster layer). Its thickness is 1/2 brick.

To ensure ventilation of the walls, special air vents are arranged in the lower row of the masonry - gaps between the ends of some bricks 10-12 mm wide at the rate of 75 cm for every 20 m2 of wall surface (Fig. 1). As a rule, each finished wall should eventually have 4 holes in the first row of masonry and 4 holes in the upper, cornice part of the house. The spacing between the holes should not exceed 4 m.

Reviews

Comments (1)

by Anonymous - 2013-07-18 23:07

Advantages of the foam block.

Foam concrete blocks are relatively inexpensive. They are lighter. The weight of your home will be less. Therefore, you do not need to build a powerful foundation under the house. This will save you money.

In addition, houses from foam blocks are erected quickly, since the blocks themselves are larger in size than bricks. During your vacation, you will be able to install the walls yourself. Laying walls from foam blocks is much cheaper than laying from bricks. It is also possible for an inexperienced builder to build walls from foam blocks, since laying is much easier.

Foam block is a material from which you can easily build elements with a more complex fit. This material is easily processed not only for external work, but also for internal work. It is easy to hide the wiring in the foam block wall, as well as water pipes.

Foam blocks are considered an ecological material. In its production, water, cement and sand are used. The percentage of impurities in it is very small. So you shouldn't have any concerns about your health.

The blocks have a porous structure. Thanks to her, they better protect the house from wind and frost. In areas with a changeable climate, this is very important. Foam concrete creates a microclimate in the house. V hot weather foam blocks will provide the optimal temperature in the room. They are ready to withstand high temperatures. Thanks to its additional ducts, this material ensures good ventilation.

Another advantage of foam concrete is its sound insulation.

For finishing foam blocks, you can use different materials: plaster mixes, tiles, natural or fake diamond, front decorative compositions and much more.

Building a house from a foam block is very profitable. Compared to brick, foam blocks are cheaper, while the thickness of the walls of such a house is 30 cm or more. In terms of thermal insulation properties, corresponding to the meter price of a brick, a foam block gives great opportunities when creating an architectural project for a house, since foam blocks are easy to saw and combine in various design and architectural solutions.

Aerated concrete, which forms the basis of the foam block, is used to produce a lot of various products for the construction of houses and cottages - floor slabs, blocks, etc. The undoubted advantage of a foam block house is the ability to "breathe", which is of course useful  for the health of their owners. In a house made of foam blocks, it is easier to bring communications - in foam concrete it is easy to groove channels for electrical wiring, heating systems and water pipes. The speed and low cost of installing foam blocks is another plus of this building material, because foam blocks are produced in large sizes, which significantly speeds up the construction of a house.

for the health of their owners. In a house made of foam blocks, it is easier to bring communications - in foam concrete it is easy to groove channels for electrical wiring, heating systems and water pipes. The speed and low cost of installing foam blocks is another plus of this building material, because foam blocks are produced in large sizes, which significantly speeds up the construction of a house.

Foam concrete does not burn, does not rot, and, unlike brick, does not lose its mechanical strength in case of fire. The only drawback of a foam block house is its unpresentable appearance, but this drawback is easily corrected by external decoration. You also need to remember that walls made of foam blocks must be protected from getting wet. Therefore, they are plastered or faced with bricks. But this minus is easily covered by a big plus - houses made of foam blocks are rightfully considered stone houses, because cellular concrete is an artificial stone, and houses made of it are durable, geoseismically resistant, strong, non-combustible and combine all the advantages of a stone house.

Bubble stone

The technology for the manufacture of foam blocks is extremely simple: liquid concrete foams, and, solidifying, forms foam or aerated concrete filled with many small bubbles. It is lightweight and durable material which retains heat well and has excellent sound insulating properties. Basically, the technology of building cottages from foam blocks is similar to the technology of building brick houses. But there are also small nuances.

Foam concrete blocks are easy to shape with a hand saw, they are easy to drill, plan and mill. Cutting aerated concrete, when building a cottage, you can create geometrically complex elements - arches, semicircular and multifaceted bay windows, as well as impeccably even gables that fit any angle of inclination of the roof. Therefore, any architectural projects easily implemented when choosing a given building material. But to increase the reliability of the structure when constructing a cottage - if the project of a foam concrete house includes more than one floor - it is necessary to put reinforced monolithic columns around the perimeter, on which the floor panels will rest. Foam concrete is a light material, so your cottage will not need a particularly strong (and, accordingly, expensive) foundation.

When building a country house from foam blocks, you can use special glue to connect them. This technology makes it possible to narrow the gaps between the blocks to 2-3 mm, and also to exclude the appearance of "cold bridges" - in such a cottage 30% more heat will be stored. However, from the point of view of reliability, the usual cement-sand mortar is much more reliable. All the same, the walls of such a house need to be insulated - if you overlay the facade with expanded polystyrene plates, you can live in it all year round.

In addition, in areas where the temperature drops below -20C in winter, roof insulation may be needed when building a country house from foam blocks. The type of roof will depend on the shape of the roof and the materials you choose to use to build it. As for interior decoration, there is also a trick here - if you invite professionals to work, they will make such a high-quality and even masonry that after that you only need to slightly align the walls. This means that you can save on rough finishing materials.

Benefits of foam and aerated concrete

The construction of houses from foam blocks simplifies the supply of communications - in foam and aerated concrete it is easier to groove channels for electrical wiring, heating systems and water pipes. The speed and low cost of installing this material also speak for the construction of a country house from foam blocks - after all, they are usually produced in large sizes, which can significantly speed up the process. Unlike wood, gas and foam concrete does not rot, does not burn and, unlike brick, does not lose its mechanical strength in case of fire. And it meets all the sanitary and hygienic requirements for the construction of cottages.

The only negative material

Aerated concrete has an unpresentable appearance, therefore, when developing a project for a house made of foam concrete, it is necessary to provide exterior decoration... In addition, when building a country house from foam blocks, it is advisable to protect the walls from getting wet. Therefore, they are either plastered (and then covered with a hydrophobic compound), or faced with brick or vinyl siding.

But still, the main advantage of foam concrete houses is that they can rightfully be called stone. After all, cellular concrete is nothing more than an artificial stone. Therefore, such cottages - durable, geoseismically stable, strong, non-combustible - combine all the advantages of a stone house.

The current demand for stone houses, brick houses and foam block houses relatively not high.

This is primarily due to the relatively high cost of construction, as well as the low number of contractors able to build such houses on high level.

The company "SIB STROY" has a sufficient staff of professionals capable of building such houses with high quality and in the shortest possible time.

Stone houses have the following disadvantages:

- High price, both the stone itself and the construction of the house;

- (often only a seriously fortified reinforced foundation with a deepening below the level of soil freezing is suitable for construction);

- long time construction;

- not on every type of soil it is possible to build a stone house;

- with a long absence during the winter season it takes a long time for a stone house to "warm up".

- Own microclimate(the stone absorbs moisture well from the surrounding air and, in case of dryness, gives it back, the effect of breathing walls is manifested).

- With proper design and installation, a stone house is warm in winter and cool in summer.(house insulation at the right approach not required).

- Excellent sound insulation.

- High fire resistance(the stone is not flammable).

- High resistance to adverse external influences (temperature drops, precipitation and others).

- Durability (of all existing materials, the stone is the most durable, the service life of such a house can be calculated for centuries).

Brick houses have the following disadvantages:

- High price, both material and work (although this price of such a house is usually significantly less than a similar one made of stone);

- high requirements for the foundation of the house(a reinforced foundation is suitable with a deepening below the freezing point of the soil, in each case the requirements for the foundation are calculated separately);

- long time construction;

- not in every area the soil allows build a brick house;

- with a long absence of tenants in winter it takes a long time to "warm up" brick house.

- Own microclimate(a brick absorbs moisture well from the surrounding air and can also give it away well, the walls of such a house "breathe").

- A brick house is warm in winter and cool in summer.(with proper design and construction).

- Good sound insulation.

- Good thermal insulation.

- Good fire resistance(brick is not flammable).

- High resistance to external influences(sharp changes in outdoor temperature, precipitation).

- Durability (brick houses, of course, are inferior in terms of this indicator to stone ones, however, subject to the construction technology, such a house will work exactly for its 100 years).

Cons of foam block houses:

- Fragility (the foam block does not hold the shock load poorly);

- High degree of water absorption(depending on the specific manufacturer, it is from 10 to 20%, foam block manufacturers claim the opposite, but here they are cunning in order to sell their goods), which in turn leads to a loss of heat insulating properties;

- Low aesthetic qualities(the foam block is not the most beautiful building material);

- Low wall holding capacity(it is extremely difficult to securely fix an elementary bookshelf in the wall, not to mention more "weighty" items);

- With a prolonged absence during the winter season it takes a long time for a foam block house to "warm up".

- High construction speed(regarding houses made of brick and stone).

- Light weight of material(relative to houses made of brick and stone), which means that they are smaller in comparison with stone and brick houses the requirement for the foundation and soil on which the construction is supposed to be.

- A foam block house is usually warmer than a brick and stone house.(in case there was no moisture collection from the environment).

- High fire resistance(the foam block is not flammable).

- Relatively low cost of foam block houses, especially when compared with stone houses or brick houses.

When summarizing the properties of stone houses, brick houses and foam block houses, we get the following:

Well-made foam concrete blocks are the best solution for private construction. Individual houses from this type of aerated concrete they are quickly erected, while they can be built independently, without resorting to expensive help from professionals. You can also improve the attractiveness of such houses yourself, with the help of wall cladding made of foam blocks. A house made of foam blocks, lined with brick, will give its owner many advantages. The main ones will be the respectable appearance of the building and its reliable protection from negative external influences.

General information about masonry

Laying foam concrete walls is easier brickwork... Foam concrete blocks are easy to saw, shape. The only thing to remember: the bases for the walls need mandatory waterproofing. For these purposes, you can use hydroisol. Roofing material is also suitable. To connect foam blocks, you can use not only a solution, but also a special glue. It will allow you to make very thin seams, securely fix the foam concrete, and protect it from water. Facing walls made of foam concrete blocks with bricks is a much more complicated job than masonry. Therefore, it should be given special attention.

Laying foam concrete walls is easier brickwork... Foam concrete blocks are easy to saw, shape. The only thing to remember: the bases for the walls need mandatory waterproofing. For these purposes, you can use hydroisol. Roofing material is also suitable. To connect foam blocks, you can use not only a solution, but also a special glue. It will allow you to make very thin seams, securely fix the foam concrete, and protect it from water. Facing walls made of foam concrete blocks with bricks is a much more complicated job than masonry. Therefore, it should be given special attention.

Preparatory work

To perform preparatory work on facing walls from foam blocks, you will need a lot of tools and building materials. Facing houses made of foam concrete with bricks is complicated by the fact that two materials cannot be installed end-to-end. A number of complications prevent this, the main of which is the formation of condensation. To avoid problems, you need to choose one of two ways of doing the work.

To perform preparatory work on facing walls from foam blocks, you will need a lot of tools and building materials. Facing houses made of foam concrete with bricks is complicated by the fact that two materials cannot be installed end-to-end. A number of complications prevent this, the main of which is the formation of condensation. To avoid problems, you need to choose one of two ways of doing the work.

- The first way: to make wall cladding from foam concrete blocks along the way of construction. But you can do this only in one case out of a hundred. This method is aimed at perfect results, so it will take a lot of time and effort;

- The second way: traditional wall cladding made of foam blocks. This process begins immediately after the end of construction. It is important to start and finish work before the first rain. If this condition is not met, then a lot of additional work will have to be done. In the article we will talk about the second method.

After completing the construction of the walls, you need to make sure that there is enough foundation stock for the construction of the facing wall. The minimum stock is 20 cm. If it turns out that you have not foreseen the foundation, you need to build up. This process will take additional time. Below we will tell you more about it.

Building up the foundation for cladding

The build-up is carried out in several stages.

The build-up is carried out in several stages.

- a trench is dug, similar to the depth of the foundation. In this case, there should be a margin on the sides. Requirements for width - from 40 cm, for stock - 20 cm each;

- the sand cushion is backfilled. It should lie at the bottom in its original state for two days;

- carefully using a diamond drill, holes are made in the main foundation;

- a reinforcing frame is created;

- the concrete surface is cleaned;

- the formwork is installed. In this case, the distance between its inner surface and the plane of the existing foundation should be 20 - 24 cm;

- concrete solution is poured. You need to wait 25 days for it to grab and gain strength, and then continue working. Polyethylene film will be required for the period of solidification of the solution - it will protect the walls from moisture during precipitation. After two days, the wooden formwork is removed.

Let us dwell in more detail at the stage of creating a reinforcing frame. Vertical reinforcement mesh formed from rods with cells 8 by 2 cm. The intersection points are welded - for this purpose, an electric arc welding machine is used. A horizontal rod is welded to each of them. In length, it should be equal to the length of the extension. The rods are necessary for the joint with the main reinforcement cage foundation. For these purposes, as a rule, a welding machine is used. You can also use liquid welding, which, however, will not be able to provide the same good reliability as the machine.

Below we will talk about what kind of insulation you need to choose for a house made of foam blocks lined with brick.

Wall insulation process

So, let's move on to the insulation of walls made of foam blocks with brick cladding. I must say that this is a difficult and responsible process. In this case, it is necessary to make a kind of layer cake to protect the walls from various adverse factors. For walls made of foam blocks under brick cladding, it is recommended to use sheet insulation. For example, it can be expanded polystyrene or mineral wool, which are attached to the walls from the outside using glue or any mechanical means of fastening. A house clad with bricks and insulation must be protected from moisture condensation, which can be done by laying a vapor barrier on the inside of the wall, as well as a wind and moisture protection film outside.

So, let's move on to the insulation of walls made of foam blocks with brick cladding. I must say that this is a difficult and responsible process. In this case, it is necessary to make a kind of layer cake to protect the walls from various adverse factors. For walls made of foam blocks under brick cladding, it is recommended to use sheet insulation. For example, it can be expanded polystyrene or mineral wool, which are attached to the walls from the outside using glue or any mechanical means of fastening. A house clad with bricks and insulation must be protected from moisture condensation, which can be done by laying a vapor barrier on the inside of the wall, as well as a wind and moisture protection film outside.

Cladding tools and materials

Having finished the work on the insulation of walls made of foam concrete for facing with bricks, you should proceed to the very process of facing the house from foam concrete blocks. Here is a partial list of building materials and special tools that will be required for this:

- brick (facing is recommended);

- medium grain sand and water;

- rubber hammer;

- puncher;

- level;

- capacity;

- roofing material.

Next, it is important to make the perfect masonry, since the durability of the work on facing the walls of foam blocks with bricks as a whole depends on the quality of its implementation. First you need to prepare a cement mortar. This process occurs as follows: dry cement and sand are poured into the container in a ratio of 1: 1.5. A drill with a nozzle is used to mix these materials. Further, as an additive, you need to apply 0.3 shares of slaked lime and, having mixed all this, you need to pour 0.6 liters of water. The result is a thick solution.

Laying and aligning the front row

The stages of laying the front row of the future house with brick cladding and sheet insulation are as follows. At the first stage, the thread is pulled, it is forbidden to go beyond it during work. Next, a little cement mortar is applied. It fits under each of the bricks. After that, the material installed in its place is nailed. It is better to use a rubber hammer rather than a metal hammer as a tool for this work, because the latter can lead to negative consequences. For example, the material may crack or split altogether.

The stages of laying the front row of the future house with brick cladding and sheet insulation are as follows. At the first stage, the thread is pulled, it is forbidden to go beyond it during work. Next, a little cement mortar is applied. It fits under each of the bricks. After that, the material installed in its place is nailed. It is better to use a rubber hammer rather than a metal hammer as a tool for this work, because the latter can lead to negative consequences. For example, the material may crack or split altogether.

Then, using the level, a control measurement is made. Further, each brick with a poke is processed with mortar. The next brick is checked against the level of the previous one. If necessary, it is knocked out with a hammer. In the last step, a trowel is used to remove excess mortar.

Of course, when building a house from foam blocks with brick cladding, not a homogeneous load-bearing wall is built, but whole system from foam concrete and brick. Therefore, between the facing layer and foam concrete blocks it is required to provide constructive connections. It is recommended to install at least five ties per m2. To do this, you can use spiral nails, which are wound with one end into load-bearing wall, and others - in the clutch. The use of basalt-plastic ties is also very popular.

The higher you have to climb while working, the more difficult it becomes. At this stage, you will need scaffolding or a stepladder.

Ventilation device and seam treatment

For ventilation of the facade in the second and penultimate horizontal rows of masonry, it is recommended to leave gaps between adjacent bricks in the plane of the masonry in increments of five bricks. As a result, we get vertical joints, unfilled with mortar. This avoids the appearance of dampness and mold in the walls made of foam blocks, faced with bricks. By the end of the work, the seams are rubbed, while the depth of abrasion should not exceed 3 mm. For this, a tool such as a rounded emery is used.

For ventilation of the facade in the second and penultimate horizontal rows of masonry, it is recommended to leave gaps between adjacent bricks in the plane of the masonry in increments of five bricks. As a result, we get vertical joints, unfilled with mortar. This avoids the appearance of dampness and mold in the walls made of foam blocks, faced with bricks. By the end of the work, the seams are rubbed, while the depth of abrasion should not exceed 3 mm. For this, a tool such as a rounded emery is used.

Thus, all the work of facing walls made of foam concrete with bricks is a rather tedious process. However, difficulties from the technical side can arise only during preparatory work. It must be remembered that vertical joints have a negative effect on the strength of the brickwork. To avoid this, each row must be laid out with a shift of half a brick relative to the other row.

Observing all the nuances described above, you will receive cozy home from foam blocks with beautiful lining and reliable insulation that will serve you faithfully for many years.