Concrete grade for the foundation slab. Construction of slab foundations for garages, cottages, houses

A sketch of any house is performed against the background of a summer landscape. Under the snow, engineering communications laid in the ground will not be visible. As mentioned above, the purchased site should be inspected in the summer. Since, initially, there may be a swamp, former peat extraction, which are not visible under the snow. Also, construction is best done in the summer, especially laying the foundation. And it's warm and the daylight hours are long. There are no long breaks to keep workers warm. Although winter has its advantages: swampy soft ground becomes hard and passable, low groundwater is frozen, and you can dig it with an excavator. And also, it is easier to take out sawn trees by dragging through the snow.

Therefore, the construction of a house begins with the construction of a foundation-slab for fragile soil. However, there is a procedure for heating concrete in mixers of concrete trucks and adding antifreeze additives to cement, which reduce the pour point of concrete, and as a result, a reinforced concrete foundation slab of acceptable quality is obtained.

According to statistics, in the Moscow region there are a number of places where the soil is weak, heaving, groundwater is very shallow. These are Pushkino, Noginsk, Orekhovo-Zuevo, Shatura. As practice shows, houses built on such soil, as a result of its subsidence, receive uneven settlement. Because of what cracks are obtained on the walls, the doors do not open. For such complex soils, it is advisable to build a house on a slab foundation. This is a monolithic slab, which will no longer give sediment. However, the slab foundation is also suitable for building houses on any soil.

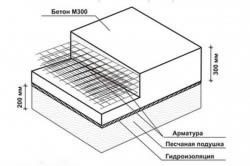

The concept of slab foundation. A slab foundation for a house, that is, a layer of good reinforced concrete up to 35 cm thick, is difficult to drill and gouge. Therefore, it will be quite difficult to arrange a basement after the manufacture of a slab foundation. You need to think about the basement in advance. For example, a basement floor, submerged shallowly, can become a basement, a workshop, and a garage. The decision to build a slab foundation for a residential building is made if a high level of groundwater, perched water or pressure artesian water is found at the construction site. The strength of the slab foundation is given by spatial reinforcement along the entire plane of the slab. Longitudinal and transverse reinforcement bars are rigidly connected to each other, utility networks are located in the space between the reinforcement bars.

For your information, the use of a slab foundation can significantly reduce the amount of excavation work. And under the load-bearing walls, together with the slab foundation, a reinforced strip foundation is arranged, or a plinth is erected by means of foundation blocks. Along with this, you can immediately plan a slab foundation for the garage. Reliable thermal insulation and waterproofing of the slab foundation is guaranteed to preserve the integrity of the slab foundation in the future. And those who have engineering communications, that is, water supply, sewerage, heating mains and electricity, are best brought to the house underground. To do this, in the design of the foundation - a concrete slab, the input of these networks must be protected from damage. And these inputs should be built along with the foundation.

Gas networks are usually carried out by air. They do not require space in the foundation. For convenience, the pumping station and the sewage treatment plant are located away from the residential building. If a heating main is approaching the house, then it must be arranged along with a slab foundation for the house. Since a monolithic slab foundation is laid on waterproofing, the foundation reinforcement should be connected to an artificial ground electrode. The fact is that under the slab foundation, over time, groundwater will leave, and the grounding resistance will increase. And the remote grounding always has a wet ground and a constant resistance to current spreading. The grounding conclusion is made near the future introductory electrical panel. This will achieve equalization of the potentials of the foundation area and obtain a reliable protective grounding of the neutral wire and lightning protection in accordance with the PUE.

The foundation project in the form of a slab for a residential building provides for the removal of groundwater from foundation slab- so to speak drainage of the slab foundation. This will eliminate the possibility of washing away the soil under the foundation, as a result of which the house will not float due to an increase in the groundwater level. The branch is built with a slope towards the roadside ditch from the house, for this reason, on the site with high level groundwater should not deepen the foundation in the form of monolithic slab. It is worth noting that water passing through crushed stone or geotextiles, which are laid in the groundwater outlet, subsequently falling into the laid plastic pipes, already filtered, goes by gravity into the ditch. The slope for this is required at least 3 ppm (1:3000). However, the design of the drain provides for the possibility of flushing the pipes with high pressure water to ensure continuous performance.

The slab solid foundation and the house itself are being built for a long time. This means that builders will need a temporary place to live, as well as to store tools. To do this, they build or deliver a ready-made light house with a kitchen and a utility block for inventory. For obvious reasons, the price of a slab foundation cannot be low due to significant energy costs. For an approximate estimate of the cost of a slab foundation, you can use the value of 12,000 rubles / m³. The rationale for this is that this includes work on geodetic markings of axes and foundations, removal of trees and vegetative soil, adding sand, crushed stone, waterproofing, reinforcement and pouring with liquid concrete, builders' accommodation.

It has been confirmed by practice that professional builders will complete the project and make the foundation on soft ground quickly, observing all the requirements of the technology. The designers will name the specified price of the slab foundation after geodetic surveys and the implementation of a preliminary design.

Requirements for the design of the slab foundation. So, in the project for the construction of the foundation of a monolithic slab, solutions should be reflected:

Binding points (benchmarks) to the power line pole, neighbor's fence, big tree)

Commissioning of engineering networks (water, sewerage, heat supply, electricity),

Specification of materials and possible replacement,

Walkway to garage

Drainage,

Estimated power and metering and distribution electrical panel for construction equipment and builders' accommodation,

Artificial grounding and lighting,

Minimizing the cost of the foundation slab.

The procedure for manufacturing a slab foundation on soft soil.

1. Marking. According to the developed project for the construction of a slab foundation, it is necessary to bind the axes of the house to reference points - benchmarks. Using a laser level, a clean floor level line is applied to the benchmarks. These points must remain intact during earthworks. Shrubs and small trees should not interfere with the ropes used for marking. Therefore, interfering vegetation must be removed.2. Removal of vegetable soil. Since the soil must be removed from large area(more than 100 m²), earth-moving equipment is used for these purposes - a bulldozer and an excavator. With a smaller area of the foundation, or if it is impossible to use equipment, earthworks are carried out manually (link) The bottom of the quarry is leveled manually, shovels must be brought to an error of 5 cm between the extreme points. You can also take a mini excavator with a leveling bucket without teeth and level the bottom with a laser level.

3. Sanding. On weak soil, after removing the vegetation layer, water should soon appear. It is necessary to bring a sufficient amount of sand in advance and fill it in place of the removed soil. Then it needs to be leveled and compacted with an electric rammer.

4. Leveling the bottom with concrete. Liquid concrete of a low grade is applied in a layer of up to 10 cm. This will finally allow you to level the bottom of the quarry. In the heat, in summer, the concrete is moistened and covered with polyethylene so that the water does not evaporate quickly. It is needed for concrete to harden and acquire a given strength. Also, concrete can be prepared on an electric concrete mixer, but then you have to do a lot of mixing. It is most reliable to buy a ready-made concrete solution and pour it using construction machines, for example, a concrete pump. All supplied concrete will be of the same brand. After the concrete has hardened, a bituminous primer is smeared on the entire surface of the foundation. This is such a sticky mastic for the subsequent gluing of waterproofing.

4a. insulated foundation. The foundation for a bath and a warm ground floor should be kept shallow and warm. By itself, heat will not be taken from anywhere, it is supplied to the layer of foundation material from the future boiler room. All possible heat leaks are also eliminated. This is called - to carry out the insulation of the slab foundation. The construction of the insulated foundation (Swedish plate) proceeds in the usual way. First, a pit is dug, geotextiles are laid on the leveled ground. Arrange an annular drainage system. Gravel is poured and leveled. But before laying the plinth and the first layer of concrete, as practice shows, where a significant amount of heat goes into the air and soil, a heater is laid on the sand and the plinth. It turns out something like a heat-insulated bathtub up to 200 mm thick for a slab foundation. Next, foam is laid in two layers (most often Knauf). Waterproofing is placed between the foam layers. And the heat insulated slab enters the thickness of the foundation through pipes with hot water as a heat carrier.

To your attention, in many apartments they arrange one of the options for underfloor heating. The boiler house for heating the house will supply hot water for both the insulated foundation and domestic hot water supply. Pipes for the heat carrier in the foundation slab are laid according to a certain pattern in order to evenly distribute heat throughout the floor except for the bearing walls. The reinforcing mesh device is combined with the laying of heating pipes. A ready-made fine reinforcement mesh is laid on the pipes to protect these pipes from damage during the construction process. After pouring concrete and careful grinding, a flat warm floor is obtained, on which it is already possible to lay a laminate, linoleum. That is, it turns out the foundation is a warm slab. And if you still make slopes in the floor and install ladders with access to the sewer, you can build a bathhouse on such a foundation.

5. Foundation waterproofing. For waterproofing the foundation slab, a built-up bituminous waterproofing material is used, for example, Uniflex EKP. It spreads along the entire length of the foundation, and then across the entire width, and specially leave tails 2 meters long outside the foundation. These tails will be needed to throw over the edge of the grillage (the future tape part of the foundation under the wall). It turns out something like a non-leaking pool. This is the purpose of waterproofing the slab foundation. When rolling out a roll of waterproofing material, it is heated with a gas propane-butane burner and the material is immediately glued to the base.

6. Formwork manufacturing. Formwork is better made from laminated plywood than from edged boards, less work, lighter and more even. The assembly should be performed only on wood screws, since everything should go smoothly, as a result it will be stronger and it will be possible to easily correct the mistakes made. Upon completion of the foundation, the formwork is easily disassembled without damage and reused elsewhere. In addition, even thin plywood can be bent and curvilinear formwork can be obtained according to the architect's intention. Horizontal alignment of the formwork must be done with an accuracy of 2 cm in opposite places using a laser level. The foundation for the house - a monolithic slab has high reliability, and changes can be made during the construction process to increase strength.

7. Laying reinforcement in the grid. The reinforcing mesh is made in two layers. The lower layer of reinforcement with a smaller diameter will work in tension, and the upper one with a larger diameter will work in compression. In order to prevent the mesh from pushing through the waterproofing with its weight, plastic dish-shaped supports for reinforcement are placed in the nodes of the mesh at regular intervals. The lower flat round dish-shaped part has a large area and reduces the pressure on the waterproofing material. Reinforcement of the foundation slab is carried out with a step of laying reinforcement of 200 ... 250 mm, so that workers can still walk along the bottom of the foundation. The longitudinal and transverse reinforcement bars are connected, of course, at the crossing points, with knitting steel wire using a hook rotating on the handle. But it is better to knit reinforcement with a knitting gun. It makes 3 turns of 0.8mm wire and a knot around a rebar in less than one second. The reinforcement in the slab foundation should not come into contact with the ground, otherwise metal corrosion will begin, water from the ground will be drawn into the concrete body and its destruction will begin.

At the calculated distance from the lower grid according to the project, the upper row of thicker reinforcement is laid with the help of supports and is also connected with wire. When pouring the foundation of the slab under the house to create a floor in the basement, a slight slope is made in the center of the room to collect water that has leaked into the basement and a pit is arranged in it. Subsequently, the formed water is pumped out of this pit by a pump into the existing sewerage system. In the place of concentrated load, where it will be located bearing wall, the concrete thickness is at least 200 mm. In the place of a clean floor, the thickness of the concrete should be up to 100 mm.

8. Pouring concrete floor. Since the volume of concrete will need about 10 m3 or more, it is better to order it at the factory and deliver it to the place in a mixer. Concrete is ordered of a higher grade, for example M300-350 on granite chips. The pouring of the foundation slab is done with a long-hose concrete pump. It will reach any point of the foundation. After pouring, concrete is compacted with vibrators. Then it is leveled with a leveler with a needle roller on a long handle. There are also manual smoothing machines for surface treatment of concrete. Rotating round vibrator with electric drive on a long handle will allow you to easily, quickly and well level a large surface. By the way, the device levels the floor even at the junction with the wall.

Making a slab foundation on your own, however, can take a long time, and the quality of this wonderful design is likely to be very low. Let the experts do it better. The use of modern devices and tools at the construction site will reduce the production time monolithic foundation slab and its price.

Pile-slab foundation. A recent Russian invention "pile-slab foundation" for multi-storey buildings, used in seismically unstable areas. Houses built in such areas are much more sustainable thanks to technology pile foundation with deep piles and slab foundation. The reinforcement of the grillage and piles is connected to the reinforcement of the foundation slab in the upper part of the grillage. The plate can be quite thin. The piles (85%) and the slab (15%) take on the load from the walls. The depth of immersion of piles is done exclusively until a solid ground is reached. Piles are installed vertically or obliquely. Top part piles are connected to the reinforcement of the slab foundation. First of all, piles are made according to the study of the soil and the project, and then the slab and grillages are made.

What types of slab foundations do we build?

Strip-slab foundation. A reinforced concrete strip under the walls and a reinforced slab connected to it can be called a strip-slab foundation. Such a foundation is very good for houses with garages or basements. The trench under the tape part of the foundation is usually made below the freezing depth of the soil. But for a light wooden frame house the tape part is not deeply made. The reinforcement of the slab is rigidly connected to the reinforcement of the tape part. Laminated plywood formwork is made prior to concrete pouring. It is worth noting that all preparatory work is carried out, as for the slab foundation.Shallow slab foundations. If, according to the terms of reference, it is not required to make a deep basement, then shallow slab foundations can be made, and practically on the ground. To do this, you will certainly need to level the soil and be sure to sprinkle with crushed stone and sand. Next, formwork is made, a layer of roll waterproofing (for example, hydrostekloizol) is laid, laid on stands and reinforcement is knitted. After that, concrete is poured, then it is leveled and the foundation is ready. Such a non-buried slab foundation is perfect for a bath and for a change house, and for a gazebo on fragile ground.

floating slab foundation. For a bathhouse and other outbuildings on a site with fragile intumescent soil, a floating slab foundation is made. He is a variety strip-slab foundation, reinforced over the entire area, the floating slab foundation withstands the entire load from the house when the soil moves. It is applied for small houses on moving subsiding soils and for simple-shaped houses, therefore, the house should not have a high base. On bulk soil, a floating slab foundation with a rare arrangement of reinforcement is arranged. The laying step is 1 ... 1.2 m. But stiffening ribs are made around the perimeter like a strip foundation.

Slab lattice foundation. Combined slab and strip foundations for relatively tall buildings called slab lattice foundation. All these foundations are essentially slab, but with a predominance of certain sizes that determine their name. Everywhere for them, with weak soil, a deep or shallow selection of soil is made, sand or gravel filling, as well as leveling the soil, reinforcement and concrete pouring.

Foundation with ribbed slab. In addition to the flat shape, the foundation slab can also be ribbed to increase the rigidity of the structure. Stiffeners, in other words, trenches under load-bearing walls and partitions to save material and labor, are completed earlier than the slab itself. The outlets of the reinforcement are then connected to the reinforcement of the future foundation by a ribbed slab. And then it is poured with concrete and a slab. According to the results of the research, the resulting design of a monolithic foundation slab is well resistant to soil bulging, and the foundation reliably serves for two to three-story houses.

Foundation plate on piles. If geological surveys have shown that the upper soil at the site of the future house is weak, soft and viscous, but strong enough at a depth, you can not make a thick foundation slab. It will be easier to install several piles that reach solid ground. They will serve as supports, and on them you can “lay” the foundation for the house - a slab. Piles are screw, driven and made in a hole drilled in the ground.

screw pile- this is a rod with welded screw ribs and screwed into the ground. A monolithic reinforced concrete pile is quickly driven into soft soil with a special machine. If you drill a deep well in the ground and fill it with reinforcement, then after pouring concrete, the pile will be ready for use in the slab foundation. Of these types of piles, the fastest and simplest are screw piles, as a result of which the foundation can be completed in a short time.

A slab foundation on piles can be used on sloping ground where the architect wishes to emphasize the terrain. Under the house you can build a garage, and above it a large veranda. And what is not unimportant, piles in the form of columns can not be hidden.

AT modern construction slabs are often installed monolithic structures, for the device of which you should know which brand of concrete for the foundation of a private house should be used.

It's important to know!

The slab foundation is also referred to as solid, floating or swedish stove. Shallow solid foundations are very often used in low-rise housing construction. The laying of this foundation is carried out literally on any soil. Thanks to the plate, the cost of work is significantly reduced, in addition, it is ideal for literally any building. In Russia, a reinforced concrete foundation of this type has been used for only a few decades, while in Europe it has been used for a long time.

Thanks to the complex production of the slab, it is possible to obtain an efficient insulated foundation with engineering common systems in a short time. The adjustable stove has a large number of advantages, i.e. it has a sufficiently high bearing capacity and is simple in design. This foundation will not be subjected to large deformations after a change in the condition of the soil under the building. Even if the soil is difficult, the slab will be the most rational, only here you should consider which concrete for the foundation of the house will be the best.

concrete mix

The slab foundation requires the use of appropriate building materials, including special insulation. It is required to know what exactly the composition of concrete should be for this type of foundation. For concreting the slab, concrete with an overall strength class of B22.5 should be taken, and its water resistance should be W8 or even more. The next important factor is frost resistance, and it should be equal to F200.

The concrete foundation used must have P-3 mobility, this will be enough. If the groundwater is high, sulfate-resistant special mixtures will be appropriate, but here it is required not only the quality of concrete, but the reinforcement used, the class of which depends on its fastening in the reinforcement cage. It is also mandatory to use waterproofing special materials required for monolithic bases.

To pour the mixture, you should clearly and correctly know what kind of concrete is needed for the foundation and how to calculate the amount of mortar for pouring. Not only the high-quality functional preparation of the concrete mixture is important, but also its ramming after pouring, which should go over the entire area at once, is also very important. The pouring of this foundation should be carried out immediately over the entire surface, and this is a very important requirement.

In addition to knowing and understanding the factor of what kind of concrete is needed for the foundation of the house, one should also take into account the aspects of knitting the reinforcement used. The device of the reinforcing common belt should be dealt with immediately after the manufacture of the formwork.

The armored belt consists of a mesh with cells of 20x20 cm on average, where reinforcement No. 14 is used. It is necessary to maintain a gap between reinforcing meshes, it is enough to make a distance of 10 cm. The fixation between these grids is due to a vertical support called a fungus.

Cooking Factors

To make a rational high-quality foundation, you should correctly select the composition of the mixture itself. Those. it is important to solve the problem of how to make concrete for the foundation and how to use it.

The brand here is selected according to the type of base and depends on the climatic zone, as well as on the geological characteristics of the soil. Further, the composition is determined by the loads from the building itself, i.e. here the weight of the future structure should be taken into account. Naturally, the mobility of the soil itself, and the presence of groundwater, and even the flowability of the soil will also be taken into account here.

The greater the mass of the building, the higher the brand of concrete mix used. If it is a simple prefabricated panel building, M200 concrete is quite suitable, and for a more serious house made of wood, M250 will already be required. For two-story buildings, the best would be M300 or more, which will provide greater strength to buildings.

If the house is built from a material such as silicate or reinforced concrete, the loads will be even greater, and the M350 brand is already used here. The brand of concrete for the foundation of a private house plays a huge role, so this aspect must be taken into account when planning and carrying out construction work.

Composition and preparation

The general composition of concrete for the foundation, the proportions of which you need to know, is almost the same as the choice of foundation. To get M100 concrete, 1 kg of cement, 4.6 sand, 7 parts of crushed stone in kilograms are taken. If you want to get M200, take 1 part of cement, 2.8 parts of sand, and 4.8 kg of crushed stone. And to obtain M400, a different composition is already used - this is 1 cement, 1.2 parts of a certain sand and 2.7 kg of crushed stone. It is recommended to purchase cement immediately before construction, as it takes moisture over time and can quickly deteriorate.

For concreting, many factors must be taken into account, and the amount of concrete itself is calculated first. This is done simply, i.e. width multiplied by height and length. If the width and total length are 10 m, and the height is 25 cm, after multiplication, 25 m3 is obtained. Often, for the manufacture of concrete material, special polymeric additives are required, thanks to which the mixture is even stronger and more resistant to external aggressive factors. Before the device of this foundation, you should clearly know how and with what concrete to pour the foundation of the house.

The brand of the mixture used must meet the conditions of the housing construction itself. If required, reinforcing special additives and plasticizers can also be included in the mixture in the required ratio, where strength depends not only on the proportion of ingredients, but also on the quality of the components. It should also be remembered that the concrete mixture should be developed within 2 hours after its preparation. If everything is done clearly and reasonably, the reinforced concrete foundation will be rational and stable, the main thing is that it will perform its functions for a long time.

A few words in conclusion

To arrange a high-quality foundation for a house, you should know how much concrete is needed for the foundation and what kind of mortar you need to prepare. If all aspects are done correctly, i.e. the mixture is made competently and rationally filled, the base will serve for many years.

Foundation monolithic slabs are included in the class of non-buried foundations. Concrete is poured into the pit, along the perimeter of which the formwork is exposed, with the installed reinforcing cage, on a compacted sand and gravel pillow. The height of the slab is from 0.2 m. The base of this type can be used on various soils. This is a great option for unstable soils. In order for the erected base to last as long as possible, be strong and reliable, it is necessary to choose the right brand of concrete for the slab foundation. There are a number of factors to consider when choosing. From its correctness will depend on material and labor costs.

The foundation slab is used mainly in areas with problematic, unstable soils, in places with groundwater close to the surface. Also, such a base is used when there is a likelihood of landslides or on bulk soils.

The technology for creating a monolithic slab is implemented in several stages:

- conduct a geodetic survey of the construction site;

- dig a pit of the required depth;

- expose the formwork;

- the bottom of the excavation is covered with a sand and gravel cushion, the thickness of which varies from 0.1 to 0.3 m;

- knit two rows of reinforcement;

- pour the mold with concrete.

The slab-type base is also called “floating”, because it can withstand quite significant ground movements without consequences for the building. Also, such a foundation allows you to build multi-storey, heavy buildings.

Big expense building material, and, accordingly, funds for the implementation of the project in practice is considered the main disadvantage monolithic foundation. Construction work is also accompanied by high labor costs, compared with the creation of other types of foundations.

The choice of concrete of the highest grade will provide a high-quality result in terms of reliability, strength and durability, but financial expenses while increasing significantly. In most cases, this will not be justified in terms of the existing loads, therefore, in each specific case, the choice of concrete grade should be approached, taking into account the factors acting on the base being built.

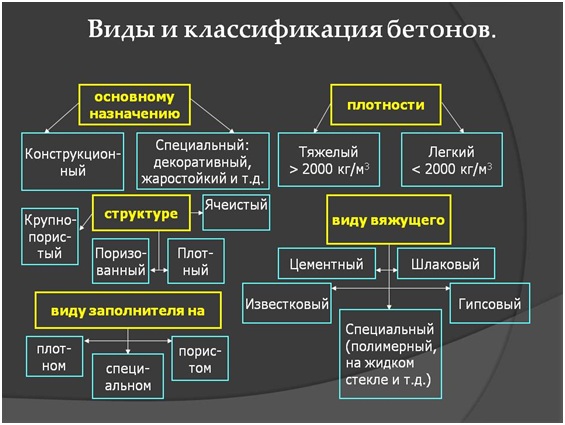

Concrete classification

The main components that make up concrete are cement, water, filler and various additives. The first acts as a binder, with the help of which other constituent elements are connected.

Scheme of varieties of concrete

Scheme of varieties of concrete The following materials can be used as fillers:

- gravel;

- sand;

- crushed stone;

- various loose materials.

Fillers are designed to reduce internal stress in concrete when it gains strength (hardening).

The final strength of the monolith depends on the presence of water in the required proportion in the solution. An excessive amount of liquid leads to a mechanical weakening of the created structure.

Classify concrete according to the criteria given in the table below.

| Classification criterion | Letter designation | Characteristics of the indicator |

|---|---|---|

| brand | M | is the most important characteristic of the material, which determines its performance |

| Class | AT | shows the guaranteed strength of the composition, gives an idea of the compression of concrete during curing |

| mobility | P | determines the optimal water content in the solution, its fluidity |

| water resistance | W | shows the degree of permeability of the monolith for water |

The material class is in the range from B3.5 to B60. In practice, B7.5 - B35 became widespread. Under the guaranteed strength is meant the load that the monolith is able to withstand in 95% of cases.

It is recommended to use compositions with a high degree of frost resistance in order to avoid the appearance of cracks after a few years due to the effect of temperature changes. The parameter setting range is from F25 to F1000. Frost resistance is an important parameter in very wet soils where there is constant contact of the supporting structure with the soil.

The value of the water resistance coefficient ranges from 2 to 20. When erecting the base, choose W2 - W12, focusing on the level of groundwater.

The final quality of the fill is determined by many factors. One of the main ones is correct ratio incoming components. The material should be of high quality.

Concrete grades

The grade of concrete defines the construction area in which it can be used. It shows how a foundation that has gained full strength will resist the impact of operational loads. The brand is the main characteristic when choosing a building material, its strength is shown in kgf / cm2. At the same time, water resistance and mobility are lowered.

Among the existing grades of concrete (from M50 to M1000), M100-M450 received practical distribution.

The table below shows the material grades and their characteristics.

| № | brand | Material characteristic |

|---|---|---|

| 1 | M100 | not suitable for the construction of foundations, but is used for the construction of blind areas, car sites, sidewalk paths |

| 2 | M200 | suitable for the construction of foundation strips with small masses, structures erected on them, and is also used for the construction of monolithic, reinforced belts and floor slabs |

| 3 | M300 | supporting structures based on this material can withstand heavy loads, so it is used for construction different types grounds and houses |

| 4 | M400 | they create from it bearing structures buildings and industrial facilities |

| 5 | M500 | structures created from this brand are distinguished by the maximum level of strength, reliability, therefore it is used in the construction of dams for hydroelectric power plants, metro, bank safes, bunkers |

Due to its high cost, the M500 is not popular. Most widespread from private developers received the brand of concrete M350. She is the best option in relation to the price of the material to its quality.

Factors determining the choice of concrete for a monolithic slab

When building light structures on a slab, such as a garage, a gazebo, a barn, a small frame or wooden house, the foundation material can be selected taking into account the current loads. Suitable concrete grades M200 and M250. Very rarely do light structures slab base. Often they manage with pile or columnar types of foundation.

To choose which concrete is best suited to create a reinforced monolithic slab in a particular case when erecting heavier buildings, it is necessary to analyze a number of factors:

- geological conditions at the construction site: type of soil, its structure, soil water level;

- climatic features of the region: temperature regime and degree of air humidity;

- the weight of the building being erected and the accompanying loads from snow, furniture, residents, household appliances and equipment.

All the factors considered must be taken into account in order to correctly determine the appropriate brand of concrete. Independent construction of the foundation (completely the entire structure) requires certain knowledge and practical skills to perform the work.

If the necessary experience is not available, then it is better to use the services of specialists who will not only skillfully build an object, but also choose the material that is suitable for specific conditions.

Concrete grades for creating a monolithic slab

In solid, rocky and sandy soil types, the entire load from the structure is evenly distributed. To build light buildings on them, you can use concrete grade M150 or M200. Heavier buildings will require the use of the M300 or M350.

Clay soil is characterized by a high degree of heaving, its volume greatly increases when freezing unevenly in different directions. In this case, only varieties M350 - M450 are suitable.

On any soil, the heavier the building being erected, the higher should be the brand of concrete used to build the foundation for it.

In most cases, to pour a monolithic slab foundation, you can use concrete with the following performance characteristics:

- from F200 degree of frost resistance;

- mobility P-3;

- the value of the water resistance coefficient, starting from W8;

- brand M300;

- class B22.5.

If soil moisture is increased on the building site or groundwater is close to the surface, then you should pay attention to Special attention on the water resistance of concrete. Proper waterproofing of the base from below and on the sides will also help to cope with the problem. When choosing a method of protecting the foundation from water, economic feasibility is often the decisive factor. It is often cheaper to use waterproofing materials than waterproof varieties of concrete.

Ready mixes offered by building trade networks contain ingredients in the required proportions. They simply need to be mixed in the right proportion with water. The marking of the finished mixture is determined by the quality of the materials included in its composition: the brand of cement, the size and strength of the particles of crushed stone and sand.

If you mix M400 cement, crushed stone and sand in a ratio of 1: 4: 2 with water (50%), you get concrete with the M250 marking. If you add a binder component M500, then the brand of the final material will be already M350.

During the manufacture of the mixture in the factory, many related factors are taken into account when marking products. At home, often the best option is to use M300 formulations, which have the recommended parameters for frost resistance, mobility, and water resistance.

Calculation of the required volume of material for pouring the foundation

To determine the amount of concrete required for the construction of a slab, it is necessary to know its volume. It is found by multiplying the height by the width and length or by the area of the base.

The table below, according to GOST 7473-94, shows the conformity of the class of concrete to its brand and the consumption of cement (M400) with a certain frost resistance, water resistance, mobility per 1 cubic meter of solution along with crushed stone, sand and water.

Knowing the volume of the slab, from the table you can determine the required amount of sand, crushed stone and cement to fill the foundation with the required strength. The working mixture in the indicated proportions can easily be prepared independently.

The technology for building a slab foundation is presented in the video below.

Recommendations for choosing crushed stone, sand and concrete grade for the construction of the base are given in the video below.

From right choice the brand of concrete used for the construction of the slab foundation will depend on the operating time, reliability and strength of the entire building. The choice of material is determined by the geology of the site and the mass of the future building. Products with the required parameters can be purchased in the form of ready-made mixtures or prepared independently.

In any construction, from residential buildings and ending with economic structures, it is necessary to have enough durable material. Today, concrete performs its function very well. But before concrete appeared in our lives, more than one millennium passed. Next, we will talk about which one is considered the most suitable for the foundation slab and about some other nuances of construction monolithic base. But first, let's talk about the origin of concrete as a building material.

Table of concrete brand and operating modes.

A bit from the history of the origin of concrete

There were times when, instead of concrete mortar, a mixture of clay, water and greasy soil was used for construction. This building material is quite a lot of years old, more than 10,000. It had a peculiar tensile strength and was used for the construction of various structures with great success.

Table of ratios of cement, sand and crushed stone in the production of concrete.

The next composition, preceding the appearance of concrete, was a mortar based on lime and gravel. The buildings erected with the help of this composition survived until today, of course, in the form of ruins. This construction took place a very long time ago, about 8000 years ago. Now this date is considered the beginning of the era of concrete construction.

Modern concrete firmly entered our lives only at the beginning of the 19th century. At this time, cement was invented, which is the main binder in concrete and other building mixtures.

Particularly popular in last years was the construction of foundations using monolithic reinforced concrete slabs. This type of foundation is distinguished by its production right at the construction site. The main component for it is concrete.

Today, ready-made blocks that have a standard shape and size are already becoming a thing of the past. This is due to the possibility of manufacturing monolithic products of any desired shape using liquid. This means that you can easily use any type of foundation during construction, and its construction will not cause you much trouble.

Back to index

Concrete, grades, selection criteria

For whatever purposes you need concrete, in any case, you should think about the question: what kind of concrete mixture to choose? The brand of ready-made concrete mortar is most often chosen, focusing on the foundation, or rather its appearance, climate and geological characteristics. Here is another small list of factors to be taken into account that are important when calculating the proportional ratio of the components of concrete for the manufacture of the foundation.

Table of ratios of concrete strength to compressive strength.

- it is necessary to know the load of the future building on the foundation and its, at least approximate, weight;

- geological characteristics of the construction site, such as soil mobility, groundwater level, soil flowability, etc.;

- arrangement of the basement and basement parts of the building, more precisely, their characteristic features.

And now in more detail. As for the expected load, this is one of the most important parameters, and it will depend on it to a greater extent for the manufacture of the foundation.

Everything is very simple - the greater the degree of load, the higher the grade of concrete required.

Without taking into account other factors, the following examples can be given.

- So, you can get the necessary degree of strength during the construction of a prefabricated panel version of the house by using M200 concrete for the cement mixture. If the house is made of wood, then concrete marked M250 is better than others.

The use of foam blocks for construction in terms of density, specific gravity, and hence the load will be similar to a wooden structure. - When erecting a building using expanded clay concrete (gas silicate) blocks, you will need M300 concrete to make the foundation. Materials with a more solid weight, such as precast concrete or sand-lime brick, respectively, increase the load, which means that you cannot do without M350 concrete, or you will have to opt for concrete with a higher degree of marking.

What to do with the calculation of the load when choosing is now more or less clear. Basically, it all depends on the building material used for laying the walls. Now let's look at the rest of the parameters listed above.

If a building object will be located on a site with sandy or rocky soil, then, without hesitation, you can use M200 concrete. This type of soil is considered the most optimal for any type of foundation. But such options are quite rare. Most often, clay or loamy soil prevails in construction sites. They are more capricious in terms of selecting the brand of the mixture.

Graph of the ratio of the class and strength of concrete.

In this case, you first need to calculate the load, in accordance with it, and you will have to purchase concrete one more category (grade) higher. Do not save, your costs will definitely show themselves in the future on the good side. Let's take a concrete example. During the construction of a building wooden frame M250 concrete is usually used, but if there is clay or loamy soil, the grade rises, which means you need M300 concrete.

Another important factor is the type of foundation chosen. It will also influence the choice of concrete mix. The decision is made in direct proportion to whether the house will have a basement or not. This is due to the need for the concrete mixture to have such a quality as water resistance.

If we take concrete with the M350 brand, then its water resistance coefficient is 2 times greater than that of the M250 brand. But to achieve perfect water tightness of the basement is possible only by performing a whole range of measures in the form of the following actions:

- applications for the construction of mortars marked M350 and higher;

- when using concrete grades of average value, it is necessary to use special bridging impregnations in the form of additives;

- waterproofing work to protect the foundation in this case must be carried out thoroughly in compliance with all requirements, which require a device that meets the parameters of reliability and high quality.

Back to index

Concrete mixtures, their grades and proportions

After it became clear which concrete is more suitable for the construction of the foundation of a building, you can proceed to the study of concrete mix grades. So, the most important in determining the brand are indicators of the proportional ratio of the mixture, in other words, the proportions of its constituent components.

Ready-mixed concrete is simply diluted with water.

- Ready-mix concrete is a composition that includes four main ingredients, such as cement, sand, water and crushed stone. Mix them, clearly observing the necessary proportions.

- Please note that the grade of the finished concrete mix will be affected by indicators such as the grade of cement used, the quality of crushed stone and sand, and the use of various special additives. As for the properties of sand and gravel, we are talking about the size of the constituent fractions, their strength qualities, etc.

Let's consider a specific example.

A proportional ratio of the following type: 1 part of cement, 4 parts of crushed stone, 2 parts of sand and 50% of the water component will result in concrete marked M250. But there is one caveat, if M400 cement was used in this proportion, then the concrete mixture will have the M250 grade, but if it is higher, for example, M500, then the concrete grade will be different - M350.

If the concrete mixture is manufactured under industrial production conditions, then, in addition to the factors listed above, other parameters that are of the nature of narrow specialization are also taken into account.

Back to index

Slab foundation - how to choose the right types of building materials?

With independent, it is necessary to pay special attention to the parameters of the concrete mixture. For a monolithic foundation slab, it is best to use concrete that meets the following characteristics:

- marking of concrete must correspond to the value of M300 or higher;

- the water resistance coefficient should not be lower than W8;

- frost resistance coefficient - F200 or higher;

- to assess mobility, the characteristic P-3 is sufficient.

Now about the reinforcing component, which is used to make the slab base of the foundation. The most common option will do. Its class must be selected depending on the method of attachment to the frame structure. For classical knitting with wire, fittings of any class are suitable.

If frame structure will be made using electric welding, then the best option there will be reinforcing steel a500s, or similar to this option. Such fittings are designed specifically for installation by welding. The diameter of the rod in this case will be more than 12 mm.

As for waterproofing, in order to reliably protect a monolithic foundation slab, any commercially available building materials will do. This refers to rolled waterproofing products. But the best option is considered to be materials on a bitumen-polymer basis.

What brand of concrete is used for a monolithic slab?

To answer the question what brand of concrete is used for a monolithic slab there are several important factors to be aware of. This includes the scope, operating conditions and much more.

A monolithic slab is a product that is poured in one step. It serves to create the most reliable and efficient, as well as floors. The area of use is extremely wide. It is rational to use the slab in cases where it is necessary to create a foundation on weakened soils, in places with shallow water flow, as well as with a small bearing capacity. To strengthen the structure, reinforcement with steel bars or mesh is used.

Considering all these factors, the optimal M250-350. It combines affordable cost and very high performance. It is worth noting the waterproofing capabilities. They allow you to effectively counter most of the emerging problems in this area. The hardening time of such a plate to the required strength indicator is about one month.

Sometimes, concrete grade for monolithic slab is quite high. For example, M350 and more. They are practically not used in private construction, since there is no need for such significant parameters. In addition, the product has a high cost.