Engineering structures

Part I. Design Basics

Building and structure concept. Classification of buildings by purpose

A building is an artificial ground structure or interior space designed and adapted for human activity. Construction - an artificial structure intended purely for technical purposes (posts, chimneys, towers, treatment facilities, etc.).

So, according to their purpose, buildings are subdivided into Civil industrial agriculture.

Civil buildings: residential public

Public buildings

agricultural: livestock poultry breeder veterinary warehouse

The concept of a room, floor. The main elements of the building and their purpose

The room is a single space fenced off from all sides inside the building that does not have subdivisions

Floor - premises located on the same level, divided, covered

basement - a floor completely or for the most part buried in the ground (also called "basement floor"); floors: aboveground basement attic basement attic technical

semi-basement, or ground floor the floor level of which is deepened from the level of the sidewalk or blind area by no more than half the height of the room;

overground - a floor (first, second, third, etc.) located above ground level;

attic (or attic) - a floor located between the roof and the ceiling above the last floor of the building (the so-called "attic floor");

attic (or attic) - a floor fenced off inside the attic space formed by a pitched roof, and is intended to accommodate residential or auxiliary heated premises; the area of the horizontal part of the ceiling of such rooms must be at least 50% of the floor area, and the height of the walls to the bottom of the inclined part of the ceiling must be at least 1.6 m);

technical - a floor intended for placing engineering equipment and laying communications.

All these and other rooms are elements of the space-planning structure of the building. The material envelope of the building is made up of interconnected structural elements - independent parts or elements of the building, each of which has its own specific purpose: walls, foundations, roofs, etc. (Fig. 1.2). Structural elements are either composed of smaller, pre-fabricated elements - building products supplied to the construction site in finished form (prefabricated plates, steps, roofing products, etc.)

The main structural elements of civil buildings include: foundations, walls, ceilings, partitions, roofs, stairs, windows, doors, balconies.

Foundations are a supporting part through which the load from the structure is transferred to the ground - the foundation.

The foundation is called natural, when the soil under the base of the foundation is in a state of its natural occurrence.

When the soil is preliminarily artificially strengthened, then such a foundation is called artificial.

Foundations are exposed to groundwater, often "aggressive, and variable temperature. Therefore, for the construction of foundations, materials with high strength, water and frost resistance are used: reinforced concrete, concrete, rubble stone.

In mass construction, foundations for the walls of buildings are constructed, as a rule, prefabricated: from reinforced concrete cushions and blocks. Usually foundations that have a flat sole are subdivided into strip foundations, which are laid under the wall, or columnar - under free-standing columns or pillars. Foundations can be piled, when the building rests on wooden, concrete or reinforced concrete piles immersed in the ground.

Walls by purpose and location in the building are subdivided into external and internal.

External walls shield the premises from the external environment and protect them from atmospheric influences.

Internal walls- separate some premises from others.

Both external and internal walls perceive wind loads on the structure, provide noise and heat insulation of the premises.

Walls are load-bearing, self-supporting and non-bearing.

Bearing walls perceive not only their own gravity, but also loads from other structures (floors, roofs, stairs).

Itself load-bearing walls transfer to the foundation only their own gravity and wind load. No ceilings or other building structures rest on such walls.

Curtain walls only shield the premises of buildings from the external space and transfer their own gravity within each floor to other load-bearing structures of the building.

Partitions are enclosing elements that divide the internal space of a building within one floor into separate rooms. They are built from bricks, gas silicate blocks, gypsum-fibrolite plates, ceramic and other hollow stones. The partitions rest on the floors and transfer their own gravity to them.

Overlapping - combine fencing and bearing functions. Interfloor ceilings are divided in the building by rooms adjacent in height.

Overlapping over the basement is called basement, and over the top floor - attic. The slabs are usually made of precast concrete slabs, decking or panels. In low-rise buildings, floors are sometimes arranged from wooden beams, to which ceiling parts made of plywood, particle boards or gypsum plasterboards are attached.

Roof - combines enclosing and load-bearing functions and serves to protect the structure from atmospheric precipitation and remove them outside of it.

It traditionally consists of rafters, to which the roof sheathing is attached. As a covering, called a roof, asbestos-cement sheets, tiles, roofing felt, roofing felt, roofing steel are used. In some buildings, coverings are made in which the functions of the roof and ceiling are combined. In this case, a roof made of rolled materials, ceramic or concrete tiles is laid over the insulated covering of the upper floor. Such a covering is called an attic. Attic roofs are also made of precast concrete slabs.

Cornice - called top part outer wall beyond its plane. The functional purpose of the cornice, in addition to its decorative qualities, is to protect the building from water flowing down from the roof.

If the building does not have a cornice, a parapet is arranged along the perimeter of its roof.

A window is an opening specially created in the wall of a house during the construction process. Light enters the rooms through the windows; they can also be used for room ventilation.

Windows are the main source of heat loss in buildings.

A door is a structural element designed to provide access, or vice versa, to restrict penetration into an enclosed space.

Doors as a sash differ in the material of manufacture. These are iron, wood, glass, plastic, aluminum doors, etc.

By location. These are entrance, interior, corridor, temple, kitchen, etc.

By design features- swing, sliding, pendulum, etc.

General purpose - emergency, fire-fighting, spare, secret, etc.

Stairs - used for communication between floors.

Place stairs in rooms with load-bearing walls (stairwells).

The part of the staircase between the landings is called the march. In the stairwells, in most cases there are also elevators.

Building requirements

Any building must meet the following basic requirements:

Functional feasibility - the building must fully meet the process for which it is intended (convenience of living, work, rest, etc.).

Technical feasibility - the building must reliably protect people from external influences(low or high temperatures, precipitation, wind), be strong and stable (withstand various loads), be durable, maintaining normal performance over time.

Architectural and artistic expressiveness - the building should be attractive in terms of its exterior and interior, it should have a beneficial effect on psychological condition and the consciousness of people.

Economic feasibility, providing for the most optimal for this type of building the cost of labor, money and time for its construction. In this case, along with the one-time construction costs, it is also necessary to take into account the costs associated with the operation of the building.

All of these requirements must be considered together. When designing a building, decisions made should be the result of optimization and consistency in meeting all requirements to ensure its validity.

Technological feasibility is the most important function of a building, which is determined by the solution of its structures, which must take into account all external influences perceived by the building as a whole and its individual elements. These influences are divided into force and non-force

Planning compositional schemes of civil buildings

Planning solutions for civil buildings are very diverse, as they reflect various functional processes occurring in certain conditions. However, this variety of solutions comes down to just how many planning schemes: cell, hall and their combinations (combined).

The cell scheme is used in those buildings where relatively small rooms of the same area are needed. The cell scheme can be solved according to the corridor, enfilade, centric (non-corridor) and sectional planning schemes.

A - corridor; b - suite; в - centric; g - hall; d - sectional

The corridor planning scheme is characterized by the arrangement of premises on both sides of the corridor. With a one-sided arrangement of the premises, the layout is called a gallery. Communication between rooms is carried out through a corridor or gallery. The corridor scheme is widely used in various civil buildings: hostels, hotels, boarding schools, administrative, educational, treatment-and-prophylactic, etc.

The enfilade planning scheme provides for a direct connection of adjacent rooms located in series, one after the other. The enfilade scheme, formerly common in residential, palace and religious buildings, has limited use: museums and exhibition pavilions, commercial buildings.

The centric planning scheme provides for a clearly defined one main large room, and secondary, smaller areas are grouped around it. Examples of this scheme can be spectacular buildings - theaters, cinemas, concert halls, circuses.

The sectional layout scheme includes a number of repeating and isolated parts-sections. Within a section, rooms can be located according to different planning schemes. This scheme is most often used in apartment residential buildings.

The hall layout is typical for buildings consisting of one room per floor - markets, exhibition pavilions, sports facilities, garages, etc.

The combined scheme is based on a combination of cell (corridor, suite or centric) and hall schemes. In it, large halls are grouped with smaller rooms. In multifunctional buildings and complexes with complex construction conditions, as a rule, several planning schemes are combined.

Part 2 Building structures

Foundations. Soil types

The base is a part of the soil mass to which the load from the structure is transferred. The foundation is called natural if the foundation is erected directly on the soil of natural constitution, and artificial, when the bearing capacity of the soil is increased in various ways.

Soils used as a base are subdivided into clay, sandy, coarse, rocky and bulk soils.

Clay soils - bonded, having plasticity in a wet state. Such soils can shrink, erode and swell when frozen.

Sandy soils are free-flowing in a dry state, which do not have plasticity in a wet state and contain less than 50% by weight of particles larger than 2 mm.

Coarse soils - unconsolidated soil containing sand and more than 50% by weight of particles larger than 2 mm. They are divided into two types. Crushed soil (gravel) - the mass of particles larger than 10 mm is more than 50% of the mass of dry soil and the soil is grit (gravel) - the mass of particles larger than 2 mm is more than 50%.

Rocky soils are the most reliable. They are durable, do not sag, erode or swell. They lie in the form of a solid massif

Bulk soils include soils with a disturbed structure, the strata of which are formed as a result of dumps, dumping of construction pits, alluvial overburden, overburden works during opencast mining.

Artificial grounds.

Artificial foundations are resorted to in cases where natural soils in their properties do not meet the normal conditions for the construction and operation of a building or structure, that is, they are weak. In these cases, the soil is compacted and consolidated or replaced with more durable ones, that is, an artificial foundation is created.

Mechanical compaction of soils can be carried out in three ways: by direct weight of the mechanisms (rollers), shock (rammers) and vibration (vibrators).

The consolidation of soils is achieved by cementation (cement is pumped in), bituminization, silicification, stabilization, and also with the help of polymer resins.

The thermal method can be carried out by injecting air heated to a temperature of 600-800 ° into the ground, or by burning various fuels (mainly diesel oil) directly in the soil. The second method is more economical.

The electrical fixing of soils is based on the fact that when passing a constant electric current through water-saturated clay soil, electroosmosis (i.e., the transfer of water from the positive pole to the negative pole), electrolysis and secondary chemical reactions occur. The result is dehydration and compaction of the soil.

Replacement of soils is used when their compaction or consolidation causes a number of difficulties.

Foundations. Foundations requirements. Classification of foundations.

Foundation-building bearing structure, part of a building, structure, which takes all the loads from the overlying structures and distributes them along the base

Requirements for foundations:

1) strength;

2) resistance to overturning and sliding in the plane of the base of the foundation;

3) resistance to aggressive groundwater;

4) resistance to atmospheric factors (frost resistance; heaving of soils during freezing);

5) compliance in terms of durability with the service life of the building;

6) industrialism;

7) profitability

a - tape; b - columnar; in - solid; g - pile

According to the constructive scheme (Fig. 2), the foundations are divided:

1) on tape (in the form of a continuous tape under all load-bearing walls);

2) columnar (in the form of separate pillars);

3) solid (in the form of a solid slab under the entire building);

4) pile.

According to the work of the foundation material under load, there are rigid foundations that work mainly in compression, and flexible ones that work in tension and shear.

Hard foundations include rubble, rubble concrete and concrete foundations... Flexible foundations are made of reinforced concrete.

According to the method of construction, foundations can be monolithic and prefabricated.

Depending on the depth of the basement basement, deep (more than 5 m) and shallow foundations are distinguished.

Pile foundations

Pile foundation Is a foundation in which piles are used to transfer the load from the building to the ground. It is advisable to erect a foundation on piles in cases where the incompressible soil layer is so deep that it is impossible to build other types of foundations, namely in the case of building a house on soft soils (for example, on peat soils or in swampy areas).

Piles are wooden, metal, or reinforced concrete rods that are buried in the ground at the base of buildings and structures to give foundation strength.

Waterproofing of foundations

Waterproofing methods are usually divided into two types. They can be performed in different planes - in the vertical, in the horizontal.

Vertical waterproofing is usually carried out from the outside of the foundation itself. In this case, waterproofing is best applied to the level of the sidewalk or blind area. Thus, the foundation will be ideally protected from groundwater, while the horizontal waterproofing is more likely to protect the walls of the basements (walls of the building) from water. This is the water that can penetrate from the base of the foundation through the capillaries of the porous materials used in the construction.

In both types of insulation, a hydraulic lock made of clay is used, the only difference is that in the vertical waterproofing between the lock and the foundation there is also a pressure wall made of brick.

Tiled foundation

Waterproofing slab foundation performed with rolled roofing material. At least two layers, with an overlap of ten to twenty centimeters. It is best to take hot bitumen mastic as an adhesive base. Waterproofing is laid directly on foundation slab, but if there are irregularities on it, then they are leveled with a screed. The insulation is laid on top of the waterproofing, and it is on it that the screed is made.

Strip foundation waterproofing can be done in several different ways.

The most economical option should be considered to be coated with bituminous mastic. Also, waterproofing can be done using roll materials. The simplest of them is roofing material, which, in addition to its economy, pleases also with its strength (stronger than coating) and durability. The penetrating waterproofing method is one of the most effective modern methods.

Pile, columnar foundation

It is extremely difficult to waterproof piles and poles. For columnar foundations, bulk-type waterproofing is most often used. For pillar and pile foundations, coating or painting waterproofing can be used. Such materials are presented, as a rule, in the form of bituminous, latex - bitumen quick-drying compositions. There is also penetrating waterproofing, which is considered the most effective and optimal waterproofing method for this type of foundation.

Walls. Classification. Requirements. Stone walls

Vertical building envelopes located above foundations are called walls. They are divided into external and internal. Internal walls that absorb loads from floors, enclose staircases and separate rooms with different temperature and humidity conditions are called capital. By the type of materials, walls are distinguished from brick, ceramic, concrete and; natural stones, block, panel, as well as monolithic reinforced concrete. In addition, the walls can be wooden, asbestos-cement or steel sheets. Depending on the structural scheme of the building, the walls can be: load-bearing, which, in addition to the mass of the walls, perceive loads from ceilings, roofs, cranes, wind, etc .; self-supporting, taking the load from the own mass of the walls of all floors of the building, as well as the wind load; non-bearing (hinged), which perceive the load only from their own weight and from the wind within one floor with a height of no more than 6 m.Depending on the complexity of the architectural structure, the walls are divided into smooth, simple, medium complexity and complex. For example, walls of medium complexity include a wall containing up to 30% of its area of architectural details. External walls must meet the requirements of strength, thermal protection, sound insulation, frost resistance, weather resistance and architectural expressiveness, while internal walls must meet the requirements of strength and sound insulation. Wall structures and materials must meet a certain degree of fire resistance of both the walls themselves and the building or structure as a whole. Wall structures should be as industrial as possible.

Stone walls

Stone walls (brick and block) are durable, strong, fire-resistant, have good sound insulation, but are massive and laborious to build, slowly warm up, but keep heat for a long time.

Depending on the type of stone materials used masonry subdivided into masonry from natural and artificial stones.

Natural materials include stone (limestone, sandstone, dolomite). It can be ragged, irregular in shape, or bedded (has approximately two parallel planes). In terms of strength, the stone can be from 25 to 100 grades.

Artificial stone materials- these are solid concrete blocks (may be with voids), usually made of lightweight concrete, and clay bricks, fired, as well as sand-lime bricks.

In the construction of buildings and structures, the following types of masonry are used: - brick; - ceramic stone masonry; - masonry of artificial large blocks made of concrete, brick or ceramic stones; F masonry made of plastic pressed ceramic bricks.

Wall elements and details

Elements and details of walls, depending on the purpose, have different names. The lower part of the wall, located directly on the foundation and protruding from its plane, is called the plinth. It is designed to protect the wall from moisture and mechanical stress; finish it with durable moisture-resistant materials. The upper protruding part of the wall is called the cornice (Fig. 1).

Horizontal protrusions in the walls (except for the crowning cornice) are called belts, vertical ones - pilasters, or semi-columns. The part of the wall located between the window openings is called a wall, and the structure that covers the opening from above is called a lintel.

Openings in solid walls overlap reinforced concrete lintels, as well as ordinary wedge and arched lintels made of unreinforced masonry. The main type of jumpers are precast reinforced concrete (GOST 948-76).

Balconies, bay windows and loggias should also be referred to the architectural and structural elements of buildings directly connected to the walls. A balcony is an open fenced area protruding beyond the plane of the outer wall. The level of the balcony floor corresponds to the level of the interfloor overlap. The elements of the balcony are its supporting structure, floor and railing. A bay window is a closed balcony located behind the outer surface of the outer wall and enclosed by walls. The bay window is part of the room. A loggia is called a platform built inside the building and open from the side of the facade, fenced off on three sides by walls.

Wooden walls - panel, frame, log (chopped) and cobbled - do not require massive foundations. It is warm and dry inside. And although they retain heat worse than stone ones and cool faster, they heat up faster when heated (Fig. 1).

Log and cobbled walls are the warmest, strongest, low-sound-conducting. They are characterized by the disadvantages of handicraft construction. Cutting corners and manually cutting grooves is unproductive, produces a lot of wood waste, and requires highly qualified carpenters. Log walls are beneficial if logs of buildings being dismantled are used for them.

Log (chopped) walls are a structure in which the walls are assembled from debarked logs (round wood).

Chopped walls are made mainly in cold areas where there is a lot of wood, as well as when using round wood from demolished buildings. These walls are a structure of logs laid horizontally one on top of the other, connected at the corners by cuts. The skeleton of a building with walls of this design is called a log house, and each row of logs in a log house is called a crown.

Partitions

Partitions are internal curtain walls, which are designed to divide a room into several parts or to highlight some functional areas in the room.

Partitions divide the internal volume of a building floor into separate rooms. Partitions must have the required strength, rigidity, in most cases soundproofing, nailing; must meet sanitary, hygienic and architectural requirements, be economical and allow industrial methods of work.

V residential buildings partitions are subdivided into interroom, interroom, into partitions that enclose sanitary facilities in the kitchen.

According to the method of construction, partitions are prefabricated, mounted from large-sized elements; made on site from piece materials (slabs, bricks, stones, lumber) or monolithic reinforced concrete,

Depending on the design, partitions can be solid solid and layered, with an air gap or with solid sound-insulating gaskets made of mineral wool, fibreboards and other materials.

In accordance with the purpose, partitions must have certain sound insulation qualities, fire resistance and strength.

To the partitions of bathrooms and kitchens, increased requirements are imposed on the hygiene of the surface finish, in addition, the partitions of the bathrooms

Overlapping. Classification. Requirements. Reinforced concrete floor slabs

Slabs - horizontal enclosing structures dividing the volume of the building into floors by height; at the same time, they are load-bearing, since they perceive vertical loads from people, equipment and materials on the floor, and horizontal wind loads transmitted from the walls of buildings, that is, the floors play the role of stiffening diaphragms in the horizontal direction, ensuring the stability of buildings.

According to their location in the building, the ceilings are divided into interfloor, attic and ceilings above the basements.

By the type of materials, the main load-bearing elements of the floors can be reinforced concrete (prefabricated, monolithic), wood and combined, in which the load-bearing beams (crossbars) are made of steel, and the floor slabs are reinforced concrete.

By constructive schemes floors are divided into beamed, ribbed and panel (non-beamed).

The main elements of the floors are: supporting structures (beams, girders and slabs); decking boards; sound, heat and waterproofing layers; structural elements of buildings.

Depending on the purpose of buildings and ceilings, in addition to the mandatory requirements for strength, rigidity, industry, minimum height (thickness) and economy, additional requirements for heat and sound insulation, fire resistance, gas, steam and water tightness are imposed on them.

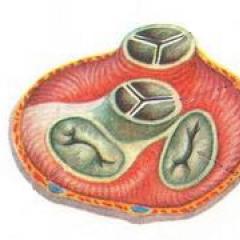

Design reinforced concrete floors... For the construction of reinforced concrete floors, slabs, floorings, panels are used that rest on load-bearing walls, load-bearing partitions or floor beams. Used in construction: hollow-core panels; solid panels;

ribbed panels (they have less weight, but their significant drawback is the need for a false ceiling); flooring; plates.

Hollow-core panels (Fig. 3) have smooth surfaces, so ceiling decoration is most often limited to painting. The seams are embedded in concrete. Hollow-core panels are reinforced with high-strength cold-drawn wire and rebar. When constructing continuous decks, conventional reinforcement is used in the form welded mesh... Floor elements are made of concrete M-200, M-300, as well as from expanded clay concrete, slag concrete, foam concrete, aerated concrete.

Roofs. Requirements. Views. Elements and structures of pitched roofs

The roof is one of the main architectural and structural elements of the building. Its purpose is to protect the building from external atmospheric influences. The roof must be strong, durable, economical and have an aesthetic appearance that is in harmony with the overall appearance of the building. By their shape, the roof can be divided into flat and pitched. Flat ones are usually used only in the construction of outbuildings: a barn, a garage, a bathhouse, premises for keeping livestock and poultry. When building residential buildings, it is advisable to use pitched roofs, which, in turn, are divided into attic and non-attic. Attic roofs can be cold (over unheated buildings) and insulated (over heated rooms). Attic roofs are usually kept cold. The attic can be used both for household needs and for arranging an additional living space in it - an attic.

Rice. 1. Types of pitched roofs: a - flat gable; b - steep gable; in - hip hip; g - lean-to (in the form of a desk); D - broken (attic) gable; e - hip hip; g, h, and - half-hip (mansard) four-pitched. For cottage-type houses, as a rule, pitched (attic) roofs are used. They consist of an upper part - a roof, a base (lathing or solid flooring), which directly supports the roof, and a supporting structure - rafters, which are usually supported by external and internal walls. To obtain a rigid frame, the rafters are fastened together, and so that the roof is not blown off by the wind, the frame is reliably tied to the box of the house.

Rice. 1. Types of pitched roofs: a - flat gable; b - steep gable; in - hip hip; g - lean-to (in the form of a desk); D - broken (attic) gable; e - hip hip; g, h, and - half-hip (mansard) four-pitched. For cottage-type houses, as a rule, pitched (attic) roofs are used. They consist of an upper part - a roof, a base (lathing or solid flooring), which directly supports the roof, and a supporting structure - rafters, which are usually supported by external and internal walls. To obtain a rigid frame, the rafters are fastened together, and so that the roof is not blown off by the wind, the frame is reliably tied to the box of the house.

Flat roofs

With the same architectural basis, the area of a flat roof was less pitched, that is, the economy of materials - on the face. Laying a flat roof itself is more convenient than a pitched one - it is easier to mount a roofing "pie" under your feet than at a high altitude in an unsafe position. Maintenance of a flat roof, preventive inspections, cleaning funnels, etc. are also not particularly difficult, and control technical devices, working with chimneys, antennas, ventilation ducts and the flooring itself in this case is not an extravagant mountaineering activity, but a common procedure. In addition, the flat roof device allows you to find additional area without increasing the outline of the structure. Such a roof, if desired, can easily turn into a terrace, garden, promenade, etc.

Roof

The roof is an important element of the home. It protects it from atmospheric precipitation, thereby extending its service life. Therefore, the roof must be waterproof, which depends on the quality of the materials from which it is made, as well as on the way they are laid. In addition, the roof must be durable, easily accessible for repair, and also have fire resistance.

With all the variety of material choices, the following types of roofing can be distinguished:

Roll;

Bulk or mastic;

Film or membrane;

Leafy;

The most durable (60 years) and fire-resistant roofing tiles are considered, which can be of several types: flat, grooved, tape, etc.

The second in terms of service life (30 years) is a roof made of roofing steel, but unlike tiled steel, it is semi-fire resistant.

Asbestos cement roofing is also fire-resistant, but its service life is no more than 20 years.

The most fragile is the roof of roll material. It is not fire resistant and lasts only 11-12 years.

Roofs are made with a certain slope, which depends on the materials used and the weight of 1 m2 of the roof together with the lathing.

The main requirements for roofs are: waterproofness, durability, fire resistance, low weight, economy in terms of initial and operating costs.

Floors. Requirements. Composition. Classification

Floor - multi-layer construction, consisting of: cover - top layer exposed to

operational impacts; interlayer - an intermediate layer (glue, mastic);

underlying layer - (preparation) cement-sand mortar; screed - serves for

leveling the surface or to give the coating a slope (concrete, tile adhesive);

base - compacted soil or floor slab.

Additionally, soundproofing layers can be included in the floor structure,

thermal insulation or waterproofing.

The name of the floor is taken according to the material from which the covering is made

(parquet, boardwalk, etc.). The gaps in the places where the floor adjoins the wall are closed

skirting board.

Floor classification:

At the location of the device:

Laid on floors;

Laid on the ground.

By coating material:

Wooden;

Concrete;

Ceramic;

Made of synthetic materials.

By type of coverage:

Solid;

Piece;

Rolled.

By the construction of the underground:

Hollow with a ventilated space between the base and the clean floor;

Void-free - having no underground space.

Floor requirements:

Strength;

Rigidity;

Hygiene;

Ease of use;

Decorativeness;

Profitability

Ladders. Classification. Requirements. Types of stairs

Ladders are used to communicate between rooms or parts of a building located on different floors, to enter the roof, to the attic, etc. Ladders are divided: by purpose - into main, service, fire, emergency; according to the type of material used for their device, they can be made of rustic, metal, in addition, they can be made of prefabricated reinforced concrete or stone steps along reinforced concrete or metal kosoura, reinforced concrete monolithic and prefabricated from ready-made marches and platforms.

The main and service stairs are located inside the building and are used for everyday use. Fire and emergency ladders are located outside the building and are designed to lift firefighters to the roof and attic and to evacuate people from the floors of the building during a fire.

The stairs consist of inclined flights and platforms. Stairs are usually placed in the stairwells of the building.

Outdoor stairs are exposed to various atmospheric precipitations and multiple temperature changes. Temperature changes and changes in humidity can lead to deformations, and in extreme cases, to the destruction of the main structural elements of the stairs.

In addition, one should take into account the possibility of icing on the steps in winter, which significantly reduces the degree of safety of the stairs. Therefore, special requirements are imposed on the materials from which the external staircase is made.

Window. Classification. Requirements. Design

Window (window opening) - an architectural detail of construction specially conceived in the structure of the building: an opening in the wall, which serves for the flow of light into the room and ventilation

ground and above-ground (on overpasses, etc.) structures - structures located above the level of the earth's surface (flat and multi-tiered), as well as in the above-ground space. (See: MGSN 1.01-98. Temporary norms and rules for the design of planning and development of the city of Moscow.)

A source: "House: Construction terminology", Moscow: Buk-press, 2006.

- - Terrestrial, or, as they are also called, aerial, algae surround us everywhere, but we usually do not notice them. And this is understandable, since it is difficult for a layman to imagine that algae, ...

Biological encyclopedia

- - land skulls are a genus of land turtles. Includes 5-7 species inhabiting the Mediterranean, the Balkan Peninsula, the Caucasus, Asia Minor and Central Asia. The most famous Mediterranean turtle ...

Biological encyclopedic dictionary

- - a complex of ground work related to the preparation of an experimental aircraft for the first takeoff ...

Encyclopedia of technology

- - The subsection "" includes engineering - construction objects, the purpose of which is to create the conditions necessary for the implementation of the production process by performing certain technical functions, does not ...

Business glossary

- - "... Ground and above ground - structures located above the level of the day surface, as well as in the above ground space ..." Source: DECISION of the Moscow Government dated 25.01 ...

Official terminology

- - "... 11. are intended for the development and improvement of fire and tactical training of air crews, subunits, units and formations for action against ground targets ...

Official terminology

- - "..." "means any sanitary means of transportation by land .....

Official terminology

- - ".....

Official terminology

- - fruiting bodies of fungi developing on the soil surface ...

Dictionary of botanical terms

- - "... Ground panels - means of outdoor advertising and information, placed on the surface of the earth, consisting of applied or embedded in the road or earth surface building materials.....

Official terminology

- - make up several families of the Triclada suborder. They often have a separate now narrow, now wide plantar plate, with the help of which they crawl and lead a terrestrial life ...

-

Encyclopedic Dictionary of Brockhaus and Euphron

- - that is, living on land. These include the following forms ...

Encyclopedic Dictionary of Brockhaus and Euphron

- - a combat weapon designed to defeat enemy manpower and equipment, as well as to destroy roads and various structures in order to reduce the pace of advance and complicate the maneuver of his troops ...

- - types of algae that live on the bark of trees, rocks and ground structures, on the surface of the soil and other out-of-water substrates ...

Great Soviet Encyclopedia

- - the general name for all turtles living on land and in fresh waters and opposed to sea turtles ...

Great Soviet Encyclopedia

"land structures" in books

GROUND BOMB STRIKES RED

From the book First and Last. German fighters on the western front 1941-1945 author Galland AdolphGROUND BOMB STRIKES RED In early June 1937, General Franco's best Navarre brigades broke through the "Iron Ring of Bilbao", and the Condor Legion took an active part in this victory. In order to ease the pressure on this sector of the front,

Appendix 18. Ground radar on June 22, 1941 in Sevastopol

From the book The Great Secret of the Great Patriotic War. Eyes open the author Osokin Alexander NikolaevichAppendix 18. Ground radar on June 22, 1941 in Sevastopol Source: http://www.8oapvo.su/history-logs/80-16-rtbr.html 16th radio technical brigade (Sevastopol) Wartime VNOS began at 1 hour 30 minutes on June 22, 1941, when from the VNOS posts located on the cape

Ground communications

From the book of the Aztecs, Mayans, Incas. Great kingdoms of ancient America the author Hagen Victor vonGround Communications Apart from the famous Inca road system (which they are somewhat similar to), the Mayan roads were the best in the Western Hemisphere, until 1792 in North America the Lancaster toll road did not open. Those sakbeob roads that are better known

LAND COLONIES OF ATLANTIS

From the book History of Humanoid Civilizations of the Earth the author Byazirev GeorgyLAND COLONIES OF ATLANTIS How the heart shrank ... wrinkles On it - from the bird "Kurla" ... And pulling their necks after the wedge Well cranes. They pull their necks after the birch, And the forest blows into the pipes of the pines ... Not autumn rain - bird's tears Pour and pour from heaven on the ground. The birds are chirping about

LAND COLONIES OF ATLANTIS

From the book Alien Civilizations of Atlantis the author Byazirev GeorgyLAND COLONIES OF ATLANTIS People suffer not from inaction, but from what they do not know - what to do and how. The High Priests foresaw the explosion of the "Firestone" long before the artificial cataclysm. As early as 400,000 years ago, they announced to their cheerful disciples that

Ground technical objects

From the book Shine and Poverty by K.E. Tsiolkovsky the author Salakhutdinov Geliy MalkovichGround technical objects It was already noted above that the idea of an air cushion dates back to the beginning of the 18th century C.E. Tsiolkovsky actively collaborated with the head of the department of the Petersburg (Leningrad) Institute of Railway Engineers N.A. Rynin and,

LAND OPERATIONS

From the book German Parachutists 1939-1945 author Querri BLAND OPERATIONS An Italian parachutist wearing an Italian parachutist helmet and a jacket with a specific camouflage pattern. He is in the service either in the German 4th Parachute Division, or in one of the Italian units (578/1931 / 11A). Crete was the last major

Land mines

From the book Great Soviet Encyclopedia (MI) of the author TSBTerrestrial algae

TSBLand turtles

From the book Great Soviet Encyclopedia (HA) of the author TSB11.3. Terrestrial types of extreme tourism

From the book Special types of tourism author Babkin AV11.3. Terrestrial types of extreme tourism Mountain biking is becoming more and more popular, despite its high cost. To seriously engage in mountain biking, you have to spend a lot of money. So, a bike for a beginner costs from $ 300 to $ 500, there are mountain bikes

Ground-based combat lasers: from chemistry to fiber optics Andrey Vasilkov

From the book Digital magazine "Computerra" № 159 (full) the author Computerra magazineGround-based combat lasers: from chemistry to fiber optics Andrey Vasilkov Published on February 06, 2013 The concept of the military use of lasers has gone a difficult path from stillborn projects costing the annual budget of a small country to fruitful programs that help

Chapter 4. Penetration of assault groups into ground vehicles

From the book How to Destroy Terrorists [Actions of Assault Teams] the author Petrov Maxim NikolaevichChapter 4. Infiltration of Assault Teams into Land Vehicles Bus and Automobile In the previous chapter we have already considered the assault on the bus, which was served at the prison gates at the request of the mutinous prisoners. A similar case is often found in

Land cruisers of the P series

From the book Hitler's Secret Weapons. 1933-1945 by David PorterLand cruisers P series The idea of gigantic "land warships" can be traced back to at least 1903, when HJ Wells wrote about the likelihood of winning a war with such armored fighting vehicles in the story "Land Battleships." By the 1930s

Ground simulators

From the book Full Immersion. How to swim better, faster and easier by Laughlin TerryGround Trainers It has been argued that working on a swim trainer is in some ways even better than swimming in a pool. The manufacturer promises that they will make your stroke perfect and allow you to practice even better at home than in the pool, etc.

What is called a structure?

1. A system of interconnected building parts and elements (load-bearing and enclosing).

What is called an engineering structure?

3. Structures performing tasks to meet the needs of industry and transport (bridges, roads, pipelines, overpasses, etc.).

What structures are considered architectural?

3.Constructions with an artificial environment characterized by appropriate parameters (temperature, humidity, illumination, etc.).

How are buildings classified by purpose?

4. Civil, industrial and agricultural.

What types of buildings (by purpose) are the train stations?

3. Public.

What types of buildings should be classified as depots, garages, pumping stations?

4. Manufacturing.

At what number of floors is a building referred to as a multi-storey building?

2.4-9 floors.

What buildings are classified as buildings increased number of storeys?

3.With 10–20 storeys.

What is a floor in a building?

3. Part of a building with rooms located on the same level.

What is called a room in a building?

2Part of the volume of the building, limited by the enclosing structures.

What floors are called underground (basement)?

2.With a floor mark below the planned surface of the earth, more than half the height of the room located in it.

Which floor is called the attic?

2.Floor, located in the volume of the attic space, with a room height of more than 1.6 m.

Which floors are taken into account when determining the number of storeys in a building?

2. Above ground floors and attic.

What tasks determine the functional requirements for buildings?

2. Providing conditions for rational planning, dimensions of premises that satisfy the normal functioning of technological processes.

How many degrees of fire resistance are buildings divided into and what is fire resistance characterized by?

3.Five degrees, characterized by the fire resistance limit and the flammability group of the material.

What flammability groups are the building materials from which buildings are built?

4. Combustible, hardly combustible, non-combustible.

How is the fire resistance of a material measured?

3. The time in hours from the start of the fire resistance test to the collapse of the structure, loss of stability, the appearance of through holes or the heating of the structure from the side, fire fire up to 140 ° С.

What is the minimum degree of fire resistance of buildings of 5-9 floors.

2.Not lower than the second.

What characterizes the degree of the building's durability?

2. The ability of a building to provide consumer qualities during a given period of operation.

What characteristics of materials of structural elements of buildings are set according to the requirement of durability?

3. Frost resistance, strength, bio- and corrosion resistance.

Engineering structures include all construction objects, except for buildings, for example, a bridge, water supply, overpass, gallery, pipeline, shelves, water towers, etc. At industrial enterprises, engineering structures differ depending on the nature of production. They can be located both inside and outside industrial buildings, as well as independent of buildings, having an independent meaning.

Engineering structures should be distinguished from technological and engineering equipment, buildings, systems engineering support, production facilities. Unlike engineering structures in industrial buildings, a technological process is carried out to obtain the main and intermediate product of production, but they are erected, like engineering structures, by construction methods.

Technological and engineering equipment is erected in most cases by mechanical engineering methods, that is, they are assembled from elements manufactured at enterprises of the engineering industries.

The main types of engineering structures and their functional purpose are shown in Fig. 1.17.

Supports and overpasses... Pedestals for horizontal and vertical equipment are intended for all kinds of apparatus in which various chemical and other processes can take place. Most often found in the chemical, oil refining, rubber industry, in factories of reinforced concrete and plastic products. Free-standing supports and overpasses for pipelines are used in cases where industrial communications are laid in an open way.

Pipelines are used with diameters ranging from a few centimeters to 2-3 m for gas pipelines. Medium and large pipelines are cylindrical beams and have a large bearing capacity, which allows them to be supported on free-standing supports with steps of 6-12-18 m.Pipelines of small diameters require more frequent supports, therefore, it is necessary to use overpasses with span structures for them. on which the transverse traverses are supported with steps of 3-4-6 m.

The pipelines can be located in three levels:

On reinforced concrete sleepers, laid on a sand cushion on the ground;

On low reinforced concrete supports 0.9-1.2 m high;

On high reinforced concrete or steel supports and overpasses with a height of 5-6 m or more.

Single-tier and two-tier freestanding supports are usually prefabricated reinforced concrete. With a traverse width of up to 1.8 m, they are made single-column T-shaped, and with a width of up to 2.4 m, single-column with separate traverses.

With a wider traverse, the supports are made two-post.

Multi-tiered supports, and in the northern and hard-to-reach areas - all supports, can be made of steel. The height of the supports to the top of the lower traverse is taken as 5.4; 6; 6.6; 7.2 and 7.8 m.

Typical two-tiered overpasses with a span of 18 m can be reinforced concrete with segmented bezel trusses, with steel lattice girders resting on reinforced concrete or steel columns. Temperature blocks can be up to 72-75 m long.

Double-deck ramps in prefabricated reinforced concrete are heavy, complex, have a low repeatability of elements, therefore, such ramps are in most cases made of steel.

Three-tiered overpasses, as well as overpasses in hard-to-reach areas and overpasses with spans of more than 18 m are made of steel.

Reinforced concrete support columns are usually made rectangular, with a cross section of 400x400 mm, clamped into separate foundations, in the form of separate pile-columns driven into the ground, pile-columns, united into flat or spatial systems by placing steel cross ties. Columns installed on single-pile foundations from shell piles or bored piles are also used. With light loads and dense soils, the columns can be installed in wells drilled into the ground, followed by concreting. Column piles are the most economical type of support. They are recommended in all cases, permissible for soil conditions.

Columns of steel supports are made rigidly connected to the foundations. It is allowed to use a hinged bearing on foundations, provided that the stability of the supports in the longitudinal direction is ensured.

Supports and overpasses are designed using the following regulatory and technical documents: SNiP 2.09.03-85 "Structures industrial enterprises"; GOST 23235-78. “Single-tier overpasses for technological pipelines. Types and main dimensions "; GOST 23236-78. “Two-tier overpasses for technological pipelines.

Types and main dimensions "; GOST 23237-78. “Stands separately for technological pipelines. Types and basic parameters ".

Unloading racks are intended for unloading various materials from railway cars, transporting materials (coal, peat, timber, sawdust) and laying pipelines.

An overpass is an open horizontal or inclined structure, consisting of a number of supports and a superstructure, designed for laying railways, motorways and pedestrian roads and communications. Overpasses for unloading various materials from railway wagons can be made from precast concrete and steel structures. Overpasses intended for laying pipelines with flammable flammable liquids and gases must have fireproof supporting and enclosing structures.

Open crane racks are designed to service warehouses equipped with overhead electric cranes with a lifting capacity of 10-50 tons and more. Steel crane beams are used for heavy duty cranes or with a lifting capacity of 50 tons or more.

Galleries. Galleries - ground or elevated, horizontal or inclined extended structure, designed for engineering or technological communications (conveyors, cables, pipelines), as well as for the passage of people.

The most widespread are conveyor and, to a lesser extent, pedestrian galleries. The passage of cables and pipelines is usually carried out along the way in combined galleries, combined with conveyor or pedestrian ones.

The width of pedestrian galleries is determined by their throughput in one direction at the rate of 2 thousand people. per hour per 1 m of width, but not less than 1.5 m.

The height of the galleries from the floor level to the bottom of the protruding roof structures is at least 2 m (in inclined galleries, the height should be measured along the normal to the floor).

Conveyor (transport) galleries are used in the mining, coke-chemical industry, building materials and products industry, in boiler houses and others. industrial sites... The conveyor gallery is based on conveyor (continuous) transport. The height of the galleries is 18, 24, 30 m. The slope of the galleries is from 1 to 20 °, depending on the technological requirements.

Channels and tunnels. Channels and tunnels are underground, closed, horizontal or inclined extended structures designed for laying communications (conveyors, pipelines, cables) or for the passage of people.

The channels are suitable for non-through, semi-through and through channels with a passage width of at least 0.6 m. The height of non-through channels is 0.3; 0.6 and 1.2 m, semi-through - 1.2-1.8 m. In channels with a height of 1.2-1.8 m and more, hatches with dimensions of 600-800 mm are provided, with a distance between them no more than 60 m.

Plates that block channels with pipelines for flammable liquids and gases passing through the building must be non-combustible. Open channels located in workshops should be fenced along the entire length with handrails with a height of at least 600 mm with a device in the necessary places of transitions.

The channels have a height of less than 2 m to the protruding parts, as a result of which the passage of people through them is not allowed. To inspect and repair communications, it is necessary to excavate and open channels.

The tunnels have a height of 2 m or more, allowing inspection and repair of communications during operation. They should be provided with passages, entrances and hatches, lighting, and, if necessary, ventilation to ensure the safety of workers in the tunnels.

Tunnels and canals should be designed in accordance with SNiP 2.09.03-85. "Constructions of industrial enterprises" and carried out, as a rule, reinforced concrete prefabricated from standard structures.

The routes of tunnels and canals should have the shortest length, the smallest number of turns, as well as intersections with roads and other communications, and will be executed in accordance with the requirements

SNiP II-89-80. "General plans of industrial enterprises". Tunnels and channels in which cables are located should be designed taking into account the "Electrical Installation Rules" (PUE) of the Ministry of Energy of Russia.

Bins and silos. Bins and silos - containers for bulk materials. The shape of the bunker depends on its purpose, the layout of the structure, the required stock of material, physical properties bulk material, type of supporting structures, etc. Recommended forms of bins: pyramidal-prismatic, cone-cylindrical, chute, parabolic.

The bunkers are of open and closed type. Open bunkers are cheaper than closed ones, but they are used only for materials that are not susceptible to atmospheric precipitation and do not emit dust harmful to human health and the environment.

Rice. 1.17. Views

engineering structures

Closed hoppers with conical lining have no empty areas when filling. On the other hand, there are always empty areas in bunkers with flat surfaces, especially when the loading opening is located on the side. Empty areas not only reduce the volume of the bunker, but also pose a hazard when explosive gases and dust accumulate in them.

The bunker parameters (shape, size and volume) should be established together with the space-planning solutions of buildings and structures, while unified grids of columns and the height of the floors of the bunker span should be adopted. The grid of bunker columns is adopted 6´6, 6´9, 6´12 m.

By the type of supporting structures, reinforced concrete, steel and combined bunkers are distinguished. As a rule, bunkers are designed with reinforced concrete. It is allowed to design out of steel funnels, tapering parts of bunkers, parabolic bins, as well as bunkers, which, due to technological conditions, are exposed to mechanical, chemical and temperature effects of bulk material and cannot be made of reinforced concrete.

When bunkers are operated in an aggressive environment, their outer surfaces are protected against corrosion in accordance with the requirements

SNiP 2.03.11-85. To protect the walls and bottom of the bunker from impacts when loading large and medium-sized material, protective steel grates are arranged above it. The inner surfaces of the hoppers, which are subject to wear from impact and abrasion, are protected by linings of various materials. At high temperatures or aggressiveness of bulk material, special wear-resistant protection is provided.

When calculating silos, the friction of bulk material against the wall surface is taken into account, which reduces the vertical pressure of the upper layers to the lower ones, which leads to a decrease in horizontal pressure. Separate silos are combined into silo buildings, which are used as warehouses for finished products and as intermediate tanks for raw materials and semi-finished products. To remove dust from the air escaping from the silos during their loading, filters are usually installed on the silo cover.

Silos are not suitable for storing materials that can cake, ignite spontaneously, or have a structure that breaks down under significant pressure. The dimensions of the silos, their shapes, the number in the body, as well as the location in the plan are assigned in accordance with the requirements of the technological process, the conditions of loading and unloading, technical and economic considerations, as well as the unified construction parameters existing for silo warehouses. In Russia, mainly round and square silos are used. Preference is given to round silos, the walls of which work mainly for central tension. When required big number small silos for storing various materials or the same material of different grades, then square silos are used, which are rational with side sizes not exceeding 3-4 m. Abroad, there are cases of hexagonal, octagonal and other cross-section of silos.

Silos can be free-standing or interlocked in silo buildings and have a single-row or multi-row arrangement. A common arrangement of round silos is one or two rows; this achieves the simplest mechanization of the supply and shipment of stored material.

For large volumes, as well as in order to better use the area of the site, a multi-row arrangement of silos is used. In this case, cavities are formed between the silos - the so-called "stars" - which can be used as additional containers for storing non-cohesive material or for arranging stairs in them, installing technological equipment and passing various pipelines. Currently, the following types of silos are used, differing mainly in bottom designs:

With a flat bottom and padding;

With a flat bottom, a steel half-funnel and a block;

With steel funnel;

With reinforced concrete funnel.

In the cement industry, double-deck silos are used. For the purpose of uniformity of space-planning and design solutions of silos, Gosstroy of Russia has approved unified construction parameters, in accordance with which the following shapes and sizes of silos are recommended: round - with a diameter of 3, 6 and 12 m; square - with a grid of 3'3m. Design of reinforced concrete silos with a diameter of 18, 24 and more meters (multiple of 6) is allowed. The grid of centering axes passing through the centers of the silos in the buildings should be a multiple of 3 m. The height of the silo walls from the bottom plate to the bottom of the over-silo slab is assumed to be 10.8; 15.6; eighteen; 20.4; 26.4 and 30 m. Other wall heights are also allowed, differing by a multiple of 0.6 m. The height of the sub-silo floor (from the floor level to the bottom of the bottom plate or the reinforced concrete support ring of the funnel) is assumed to be 3.6; 4.8; 6; 10.8; 14.4 m.

Columns of the sub-silo floor with a silo diameter of up to 6 m and a funnel for its entire diameter are installed along the perimeter of the silo walls. With a silo diameter of more than 6 m, if a flat bottom is arranged, the columns are also installed inside the silo contour. The distance between the columns is assigned taking into account the dimensions of the approximation Vehicle... Columns of square silos are installed at the intersection corners of the walls. The width of the flights of stairs, when there is an elevator for lifting people and equipment to the top of the silo buildings, is recommended to be taken cleanly at least 0.8 m, with an inclination of no more than 45 o.

In accordance with the unified building parameters

standard “Structures of reinforced concrete silos with a diameter of

6 and 12 m for the storage of bulk materials ”.

Metal tanks and gas holders... For storage and technological processing of oil and oil products, water, chemical products, mineral fertilizers, liquefied gases, ore pulp, coal and other liquid and semi-liquid products, metal tanks are used. Reservoirs can be buried, round and rectangular.

Tanks in the form of cylindrical or drop-shaped tanks are used in industrial enterprises for the closed storage of flammable liquids: oil, kerosene, gasoline, oil, alcohol and

etc. Reservoirs and cisterns can be underground, semi-underground and aboveground.

Location of fuel tanks on master plan should be linked to rail and road roads, water and coastal devices. There are three types of vertical cylindrical tanks: fixed roof, fixed roof and pontoon, and floating roof. Such reservoirs have a volume of up to 50 thousand m 3, a diameter of 4.7-60.7 m, and a height of 3-18 m.

Projects of vertical tanks with a volume of 100, 120 and 150 thousand m 3 have been developed. Vertical tanks with a fixed roof are intended for storage of slightly evaporating products and consist of a cylindrical wall, bottom and cover of various types (conical, spherical, "momentless", etc.). A "momentless" coating is a shell of negative Gaussian curvature.

Similar tanks with a fixed roof and a pontoon differ from the described tank by the presence of a pontoon of a special design floating on the product inside the tank, which ensures the reduction of evaporation during the storage of volatile products. The pontoon moves along two vertical tubular guides; when the tank is emptied, it is installed on the bottom on racks.

The space between the wall and the pontoon contour is sealed with various types of sealing gates. Vertical tanks are intended for storing petroleum products and are widely used in refineries, oil pumping stations of oil pipelines.

Vertical floating roof tanks are designed, like pontoon tanks, to store volatile products. In tanks of this type, the functions of a pontoon and a fixed roof are combined in one structure, which, in contrast to a pontoon, is designed for atmospheric loads. In this regard, the floating roof has a "water outlet" - a tubular structure that provides water drainage from the roof surface outside the tank.

All vertical tanks are manufactured at specialized plants of tank metal structures using the method of rolling walls, bottoms, central parts of floating roofs, pontoons and "momentless" fixed roofs.

Roof elements of other types, as well as other non-rollable structures (crowns of pontoons and floating roofs, stiffening rings, etc.) are manufactured by industrial methods in the form of finished large elements. The assembly of tanks is preceded by unrolling the rolls and placing them in design position... Floating roof tanks are used to store oil. They are effective and applied in southern and temperate regions. Their metal consumption is on average 20% lower than that of tanks with a fixed roof and a pontoon.

Vertical isothermal tanks, double-walled and single-walled, are intended for storage of liquefied gases under excess pressure, close to atmospheric and at low negative temperatures

(-34 about C for ammonia, -46 about C for propane, -106 about C for ethylene, -160 about C for liquefied natural gas, -196 about C for oxygen).

In double-walled insulated tanks, the outer casing is made of ordinary carbon or low-carbon steel and is designed for atmospheric loads and loads from thermal insulation in the space between the walls. The inner casing, as well as the casings of single-walled isothermal tanks, are made of cold-resistant steel grades and are designed for loads from hydrostatic pressure due to the liquefied product, overpressure in the vapor-air space, pressure from thermal insulation and vacuum. Isothermal tanks are manufactured at the factories of tank metal structures using the wall roll method, as well as by assembling from individual sheets.

Ball (spherical) tanks and gasholders with a volume of 6 and 2 thousand m 3 are intended for storing liquid and gaseous products at high internal overpressure from 0.25 to 1.8 MPa.

The calculation of spherical tanks and gas tanks is performed for the hydrostatic pressure of the liquid, overpressure in the gas space, atmospheric and other loads, taking into account the requirements of the Gosgortekhnadzor of Russia. The shell of such a tank (gasholder) is made of individual petals made by cold rolling. The assembly of the shell at the installation is carried out using a special manipulator or in another way. Assembly welding - automatic.

The tank (gasholder) is installed on tubular racks (supports), which are connected to each other.

Ball tanks (gasholders) are equipped with external shaft ladders, internal revolving observation ladders, as well as platforms for equipment maintenance. Several such reservoirs (gasholders) are combined into parks and connected by transition platforms.

Gas tanks of variable volume (constant pressure) are subdivided into gas tanks with a water basin (wet gas tanks) and cylindrical piston gas tanks (dry gas tanks).

Wet gasholders consist of a vertical cylindrical reservoir filled with water and one or two movable links - a telescope and a bell. In a large-volume gasholder, there may be several such links.

There is no small telescope in gasholders. The change in volume is achieved by extending the movable links when filling with gas and lowering them back as it is consumed. Gas tank pressure

(~ 5 kPa) is supported by special weights and the mass of the moving links. The tightness of adjacent links is ensured by water seals.

In dry gasholders, the volume is changed by moving the piston (washer) inside the gasholder.

Reservoirs of underground location, trench and casemate type with a volume of up to 10 thousand m 3 are intended for long-term storage of light oil products and liquid raw materials for food products.

Cooling towers, water towers... Cooling towers, spray pools and cooling ponds are structures designed to cool water. In tower drip cooling towers, the high temperature water entering the sprinkler, falling, passes the sieve system, crushes into drops and cools. The cooled water accumulates in a tank, from where it is fed to production.

The main structural element of tower cooling towers is an exhaust tower. Cooling tower towers are made of steel and monolithic reinforced concrete. Precast towers were not widely used due to possible destruction at the joints. Previously built low-capacity cooling towers have wood chimney towers.

For cooling towers of small and medium capacity, towers in the form of a spatial steel frame with inner lining wooden shields or asbestos-cement corrugated sheets. All these cooling towers are pyramidal in shape, with the lower tier of the tower being vertical. Structurally, the frame-sheathing exhaust tower is a lattice multifaceted structure.

Spatial rigidity of the frame is provided by horizontal lattice rings located along all tiers, corner truss posts and diagonal braces (braces) located along the inner edges of the frame. Constructive solution of the frame is subject to the possibility of mounting the tower in enlarged blocks, equal in height to one tier, and in width - to one face of the tower. The overall dimensions of the draft tower are determined based on the capacity of the cooling tower. So, the exhaust tower of the cooling tower with an irrigated area of 1600 m 2 has a height of 54 m, the radius of the inscribed circle at the bottom is 23 m, and at the top - 15.2 m. In the plan, the tower is a regular dodecahedron, and in height it is divided into five tiers.

The drainage basin of tower cooling towers is usually made of monolithic reinforced concrete. Its inner surface is protected by waterproofing (a layer of cold asphalt mastic, etc.). There is no drainage basin in dry cooling towers. Bearing structures The sprinkler is made of prefabricated reinforced concrete columns with a cross section of 300 × 300 mm with sub-columns, crossbars with a cross section of 300 × 400 or 300 × 600 mm, a span of up to 4.8 m and beams carrying a sprinkler with a cross section of 200 × 400 mm.

In irrigation devices, two types of film sprinkler are widely used (on the same reinforced concrete frame): a single-level block sprinkler made of antiseptic wooden parts and a two-level sprinkler made of flat asbestos-cement pressed sheets (1.6 x 1.2 x 0.06 m in size). Erection of metal structures is carried out in the usual way.

Reinforced concrete cooling towers usually have a single-sheet hyperboloid shape that is the most rational from an aerodynamic point of view.

Depending on the design of the irrigation device and the way in which an increase in the surface of contact of water with air is achieved, cooling towers can be of film, drip-splash and mixed drip-splash types. Structurally, the drip sprinkler is made of special shaped cross bars; film - from asbestos-cement sheets, located vertically at a short distance from each other.

The direction of air movement in relation to the cooled water in the cooling tower sprinklers can be: countercurrent (opposite); cross-exact; mixed (cross-countercurrent).

A special type of cooling towers are radiator coolers, sometimes called "dry" cooling towers. The water cooled in them gives off heat to the air passing through the cooler by means of heat transfer through the walls of the radiators. The advantage of these cooling towers is complete protection of the environment from the steam emitted by all other cooling towers.

Fan cooling towers have different volumes and shapes in terms of plan: round, square, rectangular, and polygonal. Of these, the most plastic volume is possessed by single-fan cooling towers, round and polygonal in plan.

Fan cooling towers are advisable to use in the following cases:

If it is necessary to reduce the area for placing water cooling facilities or placing them on an area with unfavorable conditions for air movement (presence tall buildings around the cooling tower, a significant number of windless days during the warm season, etc.);

When cooling the circulating water in hot climates.

Cooling ponds, as a rule, belong to off-site structures, other types of water coolers are placed directly at industrial sites.

Water towers are structures designed to increase the water pressure in water supply networks in the absence of pumping stations and in emergency cases, as well as to regulate water consumption. They are used in the systems of drinking, industrial and fire-fighting water supply of industrial enterprises, agricultural complexes and settlements.

The main elements of a water tower are a reservoir (or tank) and a support. Depending on the capacity of the tank and the height of the support (to the bottom of the tank), the dimensional diagrams of the water towers are determined. The architectural appearance of the structure depends on the shape of the tank and the support and their proportional relationship with each other.

For mass construction, as a rule, towers without tents are used, with steel tanks and supports made of reinforced concrete, brick or metal.

Tank capacity 15, 25, 50 m 3 at a support height (from ground level to the bottom of the tank), multiple of 3 m, and 100, 150, 200, 300, 500 and 800 m 3 at a support height multiple of 6 m. towers with a large tank volume.

Tanks can be spherical, conical, drop-shaped, bowl-shaped and other shapes; trunks - from shells of cylindrical, conical shape and hyperbolic outlines, as well as from lattice structures. Monolithic reinforced concrete and metal can be used as the main structural materials. Sometimes, based on architectural considerations, the tower is designed with a tent. Unique towers made of monolithic reinforced concrete are erected using sliding formwork. The tank can be mounted on the ground and then raised to the design level.

Flue pipes... Chimneys are designed to remove flue gases generated in industrial heat and power plants.

The trunk of a brick chimney consists of individual belts in height. The transition from one belt to another is carried out by reducing the thickness of the masonry with the formation of a ledge on the inner side of the trunk. The thickness of the walls of the trunk of the upper belt is not less than 1.5 bricks. For the perception of internal stresses from the outside of the barrel, clamping rings made of strip steel are installed.

Monolithic reinforced concrete chimneys are currently being designed with a height of up to 420 m, lined with lightweight polymer-cement concrete. Gas exhaust shafts are made of steel, ceramics, plastics and other materials.

Currently, there is a trend towards the use of multilateral pipes. In such pipes, each industrial unit is connected to a separate gas outlet, which makes it possible to repair pipes without stopping all units.

1.10. Special design issues

chemical enterprises

Heating, ventilation and air conditioning. Large-volume chemical production buildings (more than 3000 m 3) with round-the-clock operation, as well as buildings and rooms with forced ventilation during two- and three-shift operation, are equipped with air heating, combined with forced ventilation, using heating and circulation units. When operating in one shift, mixed heating is provided: during working hours - air heating, combined with supply ventilation, and during non-working hours - on duty, in the form of heating and recirculation units or local heating devices.

Air heating, combined with forced ventilation, is used in those rooms where vapors or gases can be emitted, which, when mixed with air, can ignite spontaneously under the influence of high temperatures. In addition, air heating combined with supply ventilation can be used in those rooms (regardless of volume) where dust can be emitted, which ignites when in contact with water or water vapor, or explosive and harmful vapors and dust (phosphorus, salt, aluminum powder, calcium carbide, etc.).

It is not allowed to use full or partial recirculation for air heating if the air contains pathogens, potent toxic substances, pronounced unpleasant odors; premises, in the air of which the concentration of harmful substances may suddenly increase (production, working with easily evaporating liquids, liquefied gases, etc.).

All rooms, regardless of their purpose, provide mechanical, natural or mixed ventilation.

In the direction of air flows, supply (injection) ventilation and exhaust ventilation are distinguished. Supply and exhaust mechanical systems are designed only where it is impossible to arrange natural or mixed ventilation.

Air conditioning is provided in cases where it is required to comply with the technological regime (for example, in the production of chemical fibers) to quickly remove hazardous substances from the equipment that have penetrated from the equipment during production malfunctions and accidents from the premises, arrange special emergency exhaust ventilation systems, taking into account the type of production, properties and the amount of hazardous emissions.

Ventilation is designed in such a way as to ensure the movement of air from clean rooms in more polluted or air leaks outside. If the supply of air is provided from outside, it is necessary to ensure the constancy of its temperature inside the room by heating the supply air or by installing additional heating devices. When designing, the places of possible emission of harmful vapors and gases are taken into account in advance for the device of local suction.

With general ventilation, if gases and other harmful substances are emitted in the room, an exhaust from the upper zone in the amount of at least one volume of the room per 1 hour is provided in all workshops and in all cases, regardless of the volume of air removed from the lower zone. Exhaust from the upper zone, as a rule, should be natural (through deflectors, shafts and - in some cases - through non-blown lanterns). Air from the lower zone is removed mechanically.

In rooms with high toxicity of emitted gases and vapors, mechanical exhaust ventilation is arranged. Full aeration is provided only in shops with an excess of heat sufficient to heat the incoming outside air (for example, in furnace departments of chemical plants, etc.). In those workshops where gases and dust are released simultaneously with the release of heat, full aeration is possible only if the supplied outside air does not interfere with the natural exit of polluted air from the room through the upper zone. In cases where this condition is not met, mixed supply and exhaust ventilation systems are provided: for the summer period - full aeration, for the winter - mechanical supply ventilation and natural exhaust.

With a large release of water vapor in the room in winter, the supply of unheated air is not allowed. Fresh supply air is supplied to the working area by mechanical fans through distribution nozzles. Fresh air must not be supplied directly to the places where gases and dust are most emitted, as the latter can spread throughout the room.

The concentrated supply of supply air to the working area is usually arranged in workshops that meet the following requirements: technological equipment is located in regular rows with free passages between them; the equipment has local suction, and dust is not emitted in the premises; at small amount there are no fixed workplaces for the maintenance personnel even with a closed technological process.

Emergency exhaust ventilation is provided in cases where many hazardous products can enter the premises in a short time. The air removed by emergency ventilation units must be discharged above the building covering, but not closer than 20 m from the chimneys. For emergency ventilation, axial fans installed in niches are used. At present, the automatic activation of emergency ventilation from gas analyzers configured to the maximum permissible concentrations of gases or vapors according to sanitary or fire safety standards is widely used, with a simultaneous sound signal.

Air conditioning is provided in windowless, hermetically sealed rooms. External air intake for ventilation is done in the most remote places and protected from the emission of harmful gases, vapors and dust. Minimum distance between the air intake and the nearest source of its pollution (exhaust pipes, exhaust ventilation shafts, chimneys, sewer wells, etc.), at least 6 m vertically and 10-12 m horizontally are taken.